This isn’t rocket science, but our high-speed tour of Britain’s car factories still owes something to the line uttered by John F Kennedy when he committed the US to the space race: “We do these things not because they are easy, but because they are hard.”

That’s doubly true when it comes to getting to Sunderland in time for 9am if your starting point, like ours, is Twickenham in South-West London.

The idea is simple: visit every significant car manufacturing site to put a sense of scale on what remains Blighty’s most dynamic industrial sector. Readers with longer memories might remember that we’ve done something similar before, with a 2005 expedition serving as the partial inspiration for this one, but it has also been made topical by Brexit and all the unanswered questions about what it will mean for our car industry. Whereas the original tour was a marathon, including taking a car from each factory to the next (see ‘All change since 2005’, below), this one is definitely a sprint, given the need to compress a tour of the 16 UK sites that produce more than 100 road-legal cars a year into just three days.

Day one

For transport on this high-mileage mission, we’ve opted to go straight to the top. The Bentley Bentayga Diesel has been selected on the basis of its Britishness and general niceness as a place to spend time, but also by the fuel range given by its huge 85-litre tank. There’s steady rain throughout our four-hour trip from Autocar HQ to Wearside, but the gauge still reads half full as we arrive.

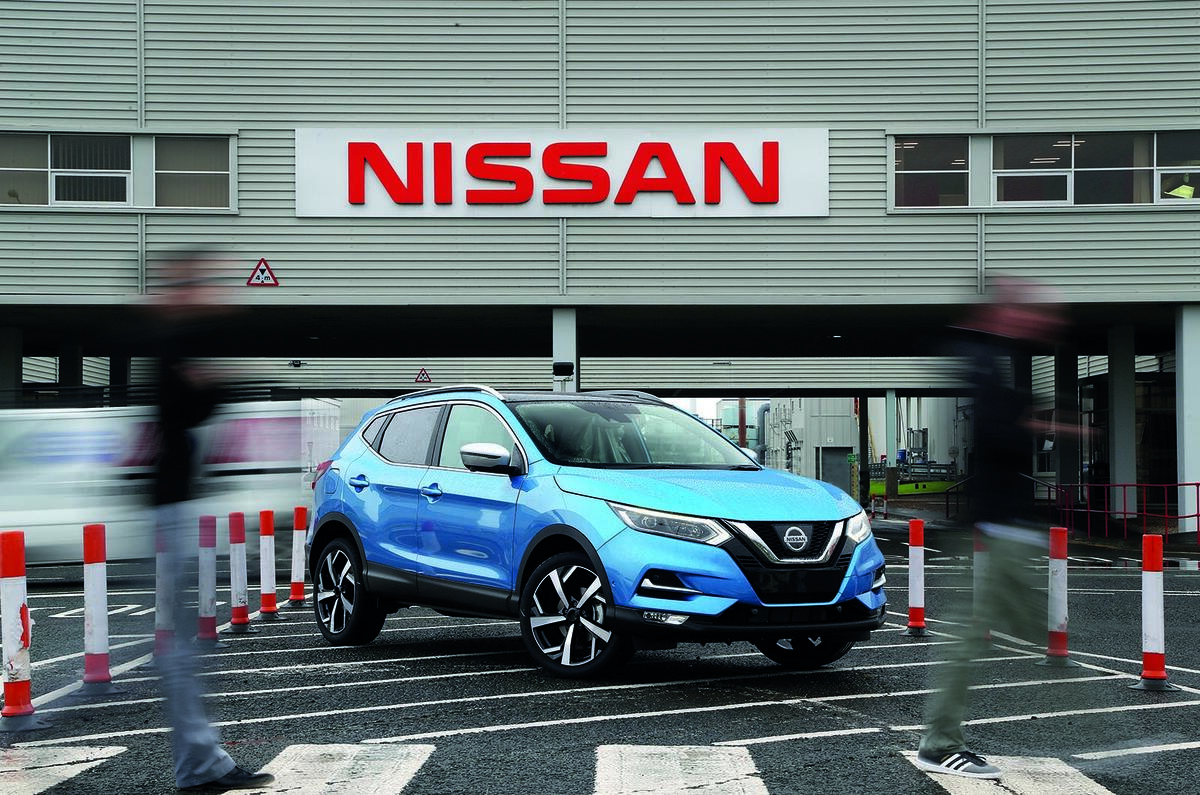

Sunderland is a long way from the heart of the British car industry, but the Nissan plant is one of the most productive in Europe. Jaguar Land Rover might produce more vehicles overall, but no other British plant got close to the half-million Nissan Qashqais, Nissan Jukes and Infiniti Q30s that Sunderland built last year, along with a smattering of Leafs. A total of 7000 people work here and its importance to the local economy is emphasised by the fact that the entire workforce is being given the freedom of the city two days after our visit, although nobody we speak to seems sure what this will entitle them to do. There’s just one problem, though. Our plan is to photograph the whole production line-up outside each factory, but there’s an absence of available cars here, with only a box-fresh Qashqai waiting to go. “You wouldn’t believe how hard it is to get cars in a car factory,” says plant PR Stuart Boyd, ruefully.

Join the debate

Add your comment

Sam Jenkins wrote:

Hard Brexit might mean the Police will be driving Jags again!!!!

I suppose if there was an "Hard Brexit", maxbe we'd all buy British again???

Just think all the Police & Vilans will be driving around again in Jags again, just like in the Sweeney!!!

All the Ice Cream Vans & Ambulances would be based on Bedfords (Vauxhall Vivaro's) & not Mercs!!!

Cor blimey gov'ner, I'm warming to that idea!!!!!!!

jagdavey wrote:

As Paul pointed out earlier, the Uk buys lots of cars from the Germans. In fact we import more cars from Germany than does the USA. Or than does the whole of Asia combined. And that's just from Germany, never mind all the ones from France, Italy, Spain, Czech Republic, Sweden or Belgium. And don't forget to add on top of that all those vans and lorries we buy from VW, Mecedes, Renault, Volvo, Fiat and so on.

But it's the German ones which are most important in the current situation. Then add in all the other German goods from the likes of Siemens, Neff, Bosch, Staedtler, Bayer, Liebherr, Jungheinrich, Adidas, Hella, Haribo, Osram, Miele, Puma, BASF, Recaro, Becks, Steinway, Stabilo, Loewe, Sennheiser, Knorr, Hugo Boss, Leica, Carl Zeiss, Aldi and Lidl, because no country buys into the German equals quality spiel like the UK does, we are Germany's best export market. The Germans say what's what in the EU, and German industry is going to tell Merrkel that she'd better make sure they don't lose the UK market or they'll be stuffed. Because if there's no free trade deal with the EU, the Japanese makers won't be leaving the UK, they'll be selling us loads of cars that we used to buy from the Germans, and laughing their cocks off all the way to the bank.

Hard Brexit

I hope you are right & that instead of all those German cars (including all the Ford's), we'll all buy Japanese "British" built cars & of course Jags & Land Rovers.

Buy you bet the EU will make it difficult for the UK.

jagdavey wrote:

The EU are in no position to make things difficult for us. We are leaving their corrupt and undemocratic little institution, and will be deciding our own future from now on, free from the constraints of their protection racket, which is all their Paneuropa project is when one boils it down. An attempt to force members to continue with threats of reprisal if they try to leave. The gangsters say we're going to get petrol through our letter-box, but once we've gone they'll have bigger problems on their own doorstep about which to worry.

As for JLR, the bosses there need to grow a pair, scrap the Slovakia plans and keep the jobs in Britain, like they should have done in the first place, instead of taking EU bribes to betray British industry.

For what...

Maybe a lifestyle like Norway - Norway was ranked as the best place to live in the world in 2015 according to the UN.