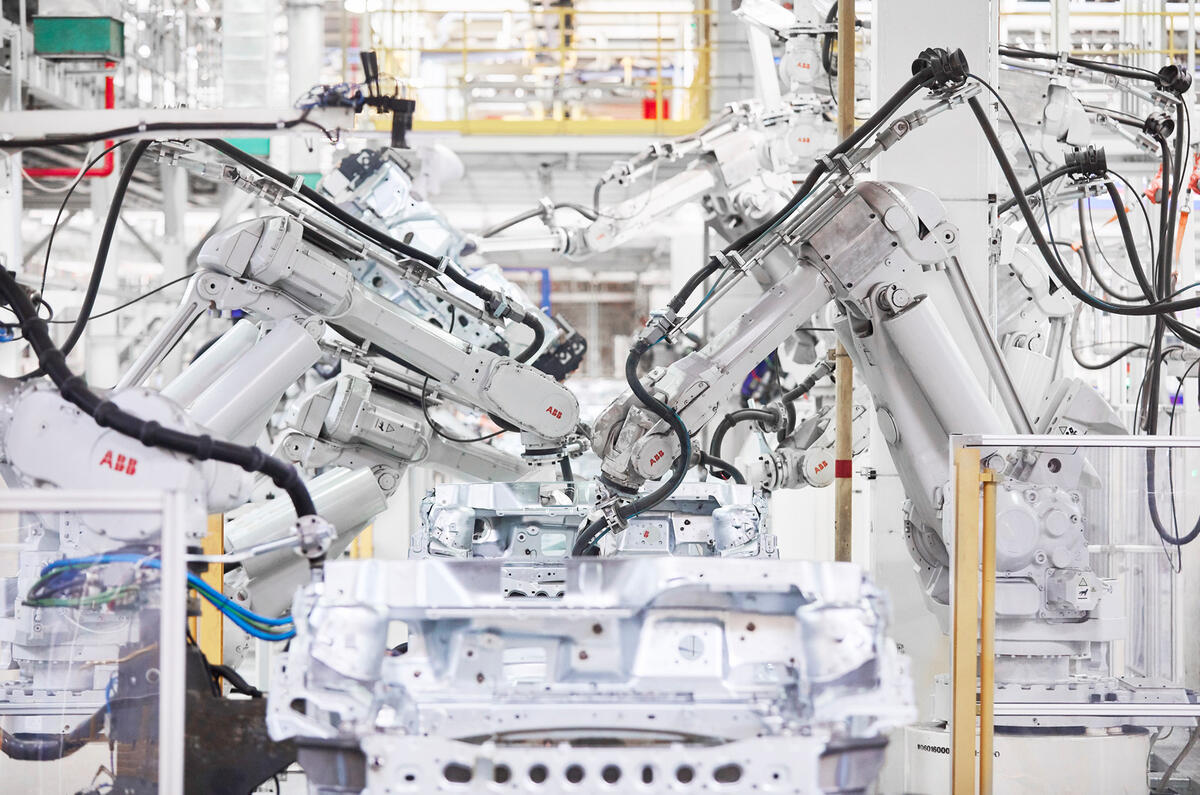

A radical reshaping of automotive production lines, to include flexible manufacturing cells, robotic guided vehicles and automated parts warehouses moved to trackside, are the key to making electric cars affordable, Europe’s second-biggest maker of robots, ABB, believes.

ABB is pushing a radical new production system that abandons the traditional assembly/trim line, with its dozens of sequential assembly stations, in favour of multiple flexible manufacturing cells between which vehicles and parts bins are hauled on trolleys by automated mobile robotic vehicles.