The launch in September of Audi’s first pure-electric car, the E-tron, and the increased amount of digital content in such models mean the German firm is completely reinventing the way it approaches quality procedures at its factories.

“Audi is going through its biggest change ever as it transitions to become a digital company,” said head of quality assurance Werner Zimmermann, “and quality is one of our core competences, with our customers having expectations for the function, comfort, value and reliability of our cars.”

All of the quality departments, covering 500 vehicle functions and their 2800 staff, mostly based at Audi’s Ingolstadt HQ in Germany, are adopting new procedures to deal with the increased electrical complexity of the Audi of the future.

Audi RS5 Sportback revealed with 444bhp turbocharged V6

For example, a battery-electric Audi will be equipped with more than 100 computer control nodes and generate 100,000 signals in its electrical wiring, compared with the 12,000 signals that a typical combustion-engined car generates today.

Audi’s quality teams get most directly involved in new car launches in the final six to 10 months of the typical four-year product cycle, when they can best influence the quality of the finished model.

Mind the gap

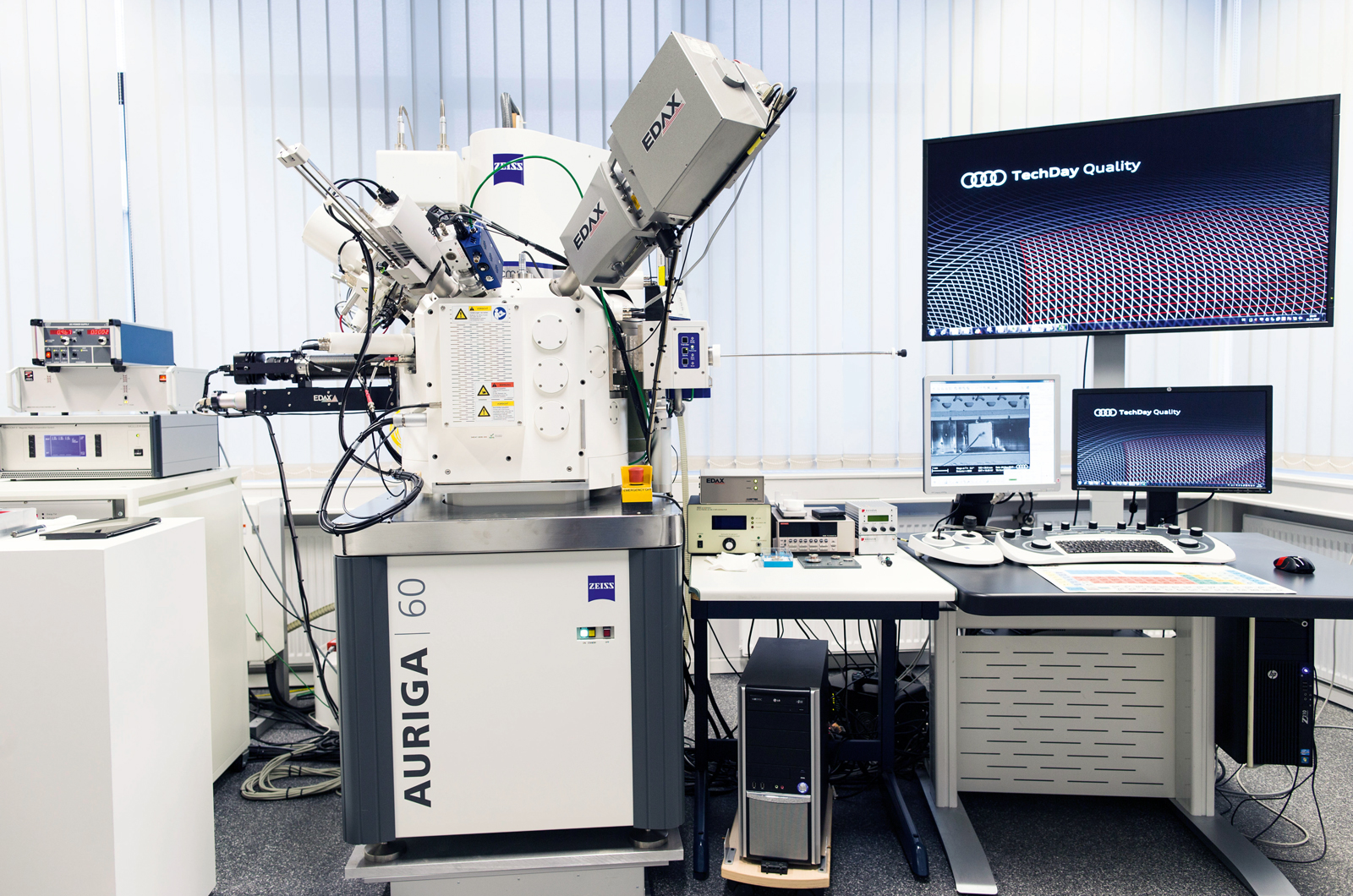

An Audi’s tight panel gaps don’t happen by luck. Metrology is the science of measurement and Audi is using digital advances to improve the correlation between design and manufacture to improve the 0.2mm panel-gap tolerance.

Currently, a master jig is created 10 months ahead of Job One (the start of production), when production tooling becomes available to fine-tune the body to a perfect panel fit. Audi uses the same 0.2mm tolerance in its interiors, which also have their own master jig. A new bit of kit in the department is an optical jig, built around two 16MPM digital cameras mounted on robotic arms, which can build up a 3D picture of a complete production body in four hours – a 100GB file. The ‘tactile’ scanners of old took 48 hours to do a similar but less thorough job.

Join the debate

Add your comment

All hot air

This is a company that struggles to design decent mechanical suspension and as far as I know their real claim to motoring fame is to use "2000 nuts and bolts in the interior" to impress passengers and bystanders.

What does that mean?

Becoming a “digital” company. That means absolutely nothing to me. Lots of use of the word digital, and as far as I remember it’s a bunch of 1’s and 0’s. Management twaddle.

Hard choices

The fact that the Audi will undoubtably be at least 18%more expensive in base format than the IPace does place us in another mind. German v British (except it isnt British anymore than a Nissan Leaf is) The design is going to be the factor. ntil we see the Audi in finished form not ruling can be made. The IPace has pinched the glory for now but AUDI has the advantage of hindsight and they wont mess up or miss up anything where the Jag may fall short of.