Bentley’s W12 is more than just an engine: it’s a byword for the British company’s heritage, its current positioning as a luxury brand and also its future ambitions.

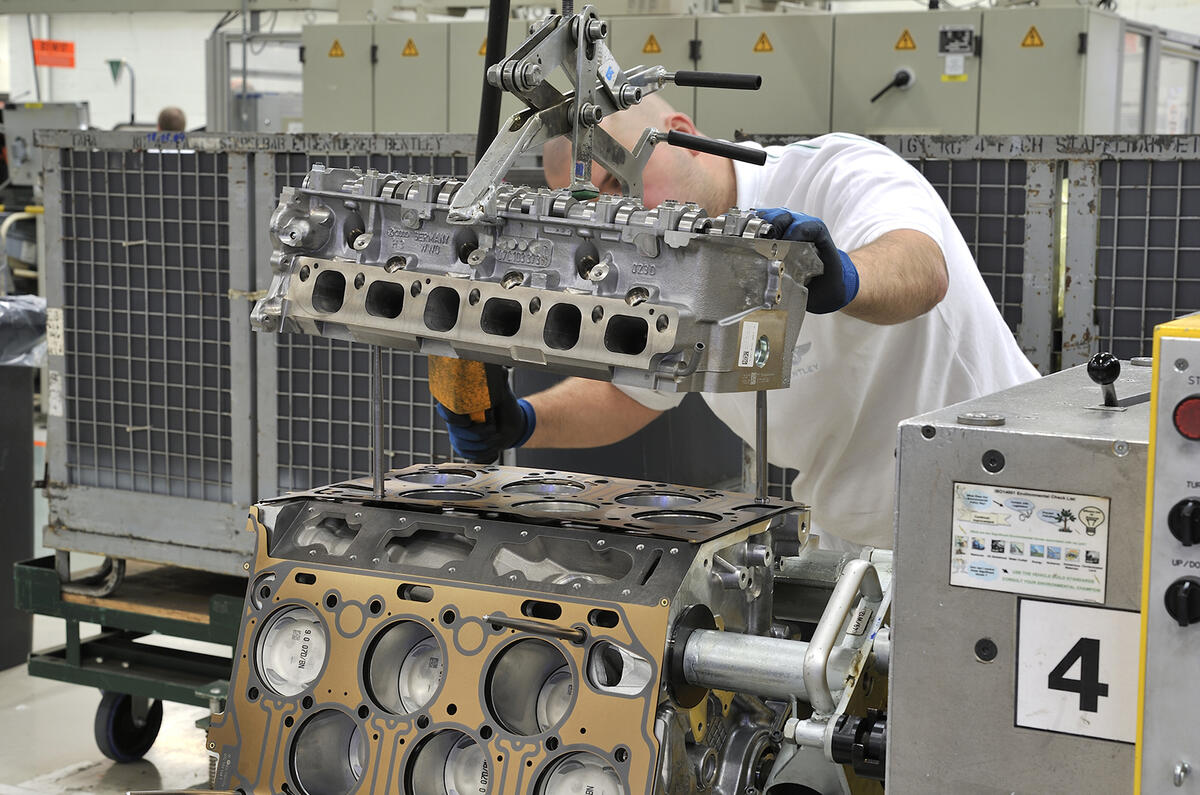

In the modern age of downsizing and efficiency-chasing, that the engine has a long-term future is both an eyebrow-raiser and a huge shot in the arm for the 100-strong team responsible for building the W12 at the former fighter plane engine facility in Pyms Lane, Crewe.

Two years ago, when Bentley introduced the twin-turbocharged V8 – complete with its fuel-saving technology and significantly lower CO2 emissions – into the Continental range, it could have been assumed that it would signal the beginning of the end for the thirstier W12.

Nothing could be further from the truth, says Paul Jones, the company’s director of product management: “We have no intention whatsoever of dropping the W12 any time soon.”

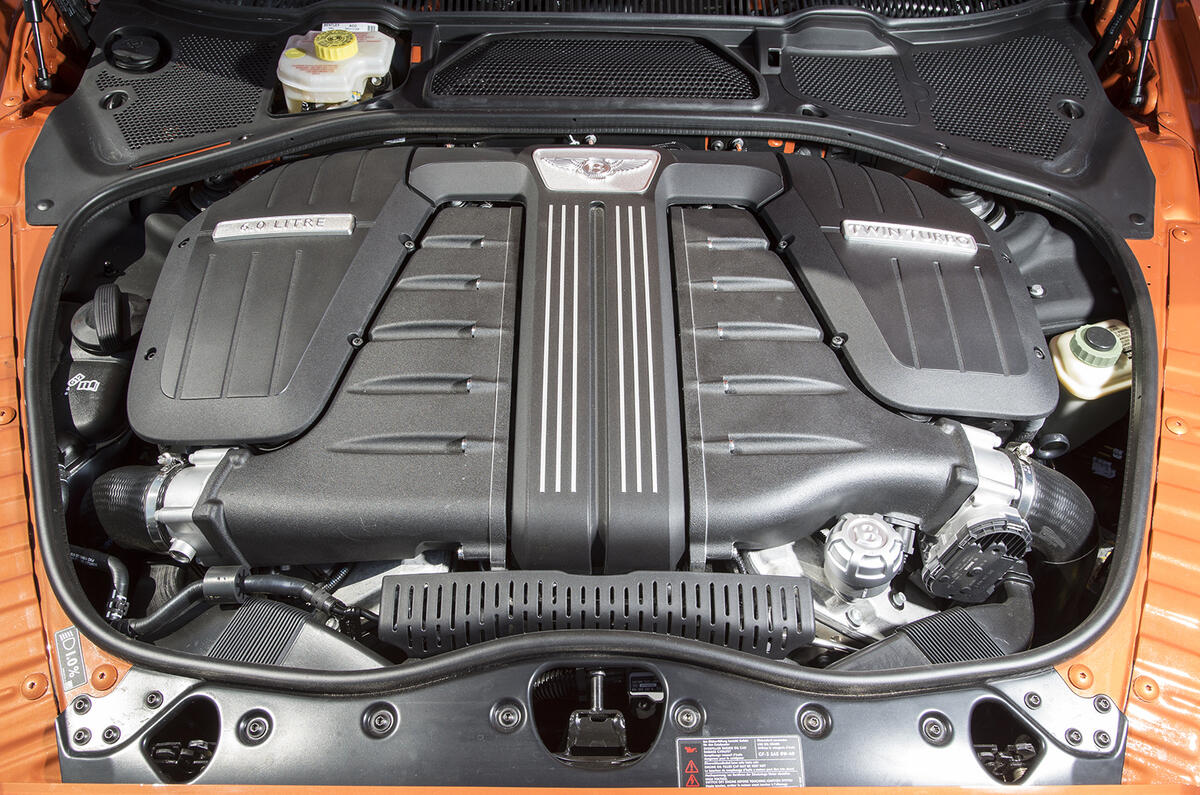

Bolstering the future for the generously cylindered powerplant is sustained customer demand, while Bentley’s technical wizards continue to tease more power and torque out of its 5998cc.

Installed in the Continental GT Speed, the latest W12 produces 626bhp and 607lb ft. Back in 2000, when Bentley inherited the Volkswagen Group’s 12-pot engine and set about re-engineering it, the unit produced 414bhp and 406lb ft.

The key figure is the maximum torque, which has been spread across a wider rev range and now comes in at 2000rpm, as opposed to the original unit’s peaky 3750-4500rpm range.

Read the full Bentley Continental GT Speed first drive

Of the latest revisions, which have come from engine management and turbo pressure alterations, Jones says: “This is the latest chapter in the W12 engine story, but not the last.”

Indeed, the future looks increasingly bright. Pyms Lane has been made the Volkswagen Group’s centre of excellence for 12-cylinder engines. That’s significant for several reasons: it means financial investment in the plant, creates about 100 new jobs, paves the way for increased production and means that Bentley will become an engine exporter for the first time.

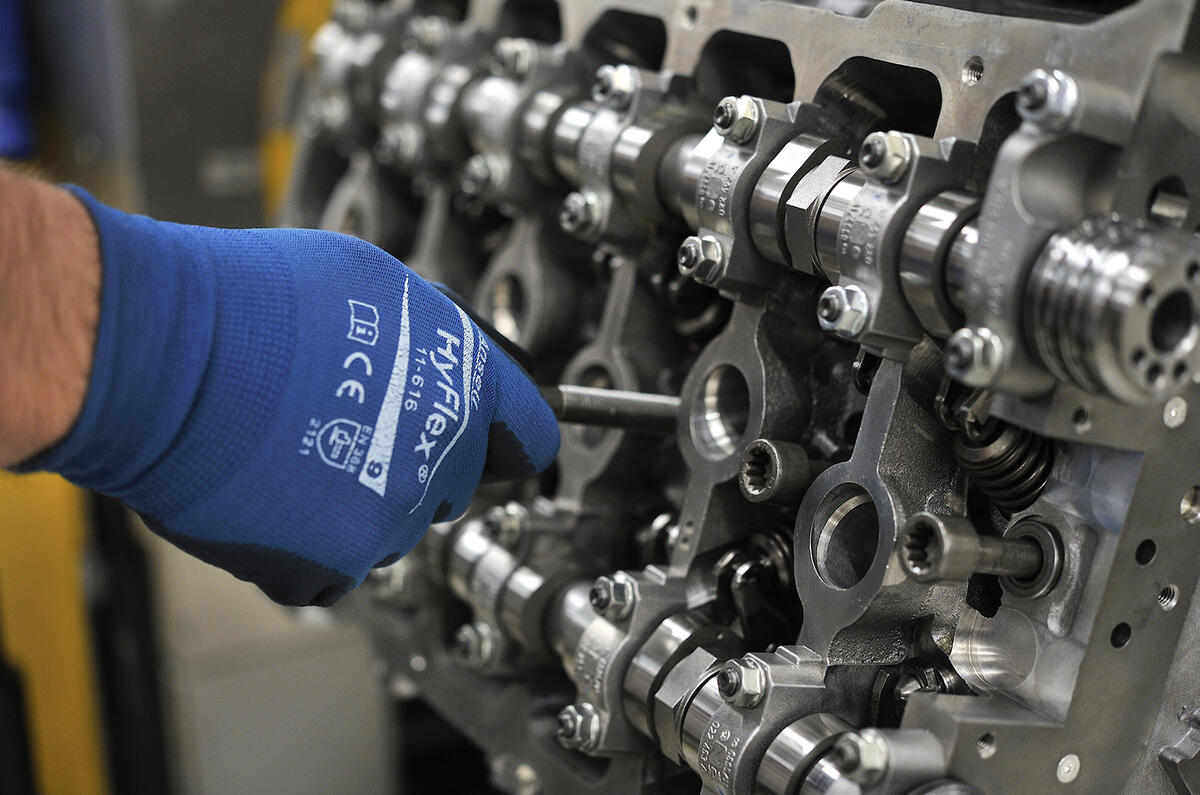

So what drives Bentley’s passion for the W12 format? The engine – which is best described as two narrow-angle V6 engines sharing a common crankshaft – delivers the blend of refinement and power that suits the image it wants to portray.

“We’re always striving for these classic Bentley characteristics, which are maximum torque at low speed, almost like a locomotive,” says Jones. “A Bentley should be about huge, effortless acceleration. It shouldn’t feel like it is trying.”

Join the debate

Add your comment

VR12, not W12.

There's been talk of this engine replacing the pushrod V8 in the bigger Bentleys, which would be its second use in a natively RWD car, the first being in the VW Touareg.

the W12 is an engineering

British 12 cylinder manufacturing.

Reply to concinnity...

Unfortunately the Bentley product and reputation now suffers from a lot of VW-Group twaddle.

So both the Germans are as