Jaguar has saved 500,000 tons of greenhouse gas pollution through the use of recycled aluminium in its Jaguar XE.

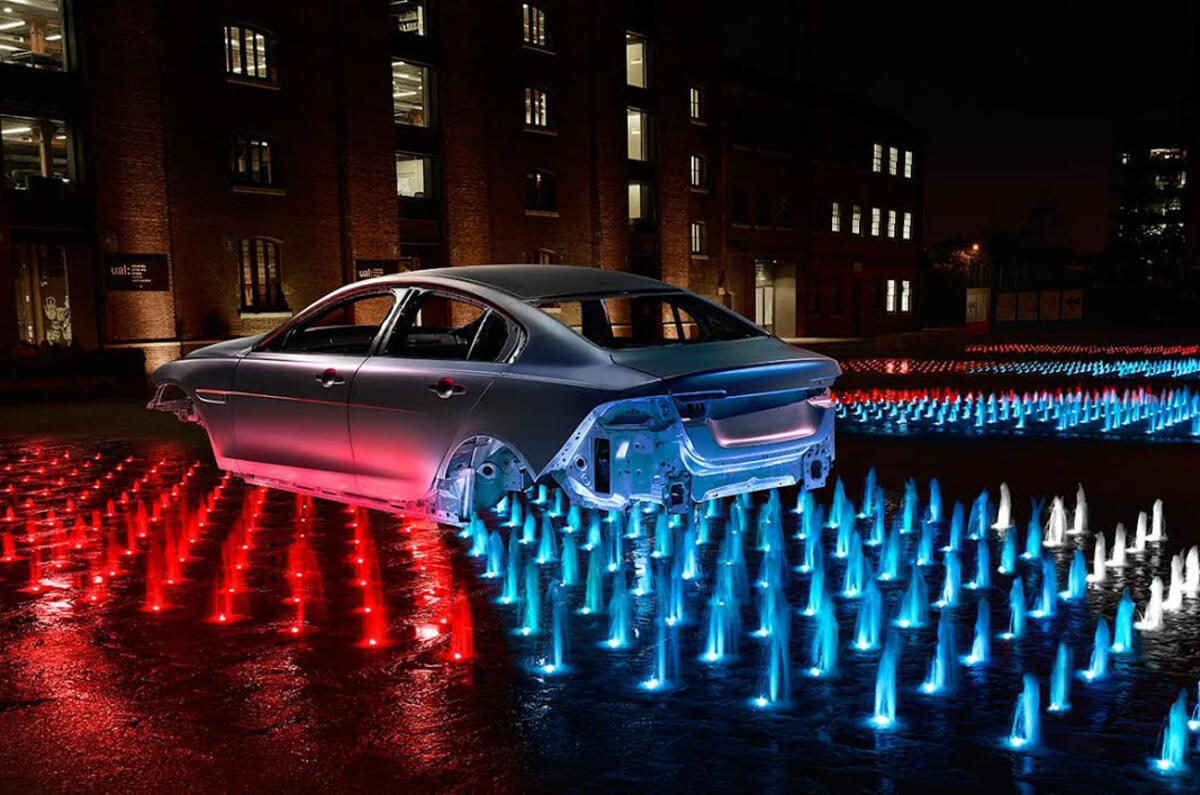

The Coventry-based car maker has been using a closed-loop aluminium recycling process to construct the XE’s bodyshell, and says that after 12 months of production it has reclaimed more than 50,000 tons of the metal – about the same weight as 200,000 XE bodyshells or six Eiffel Towers.

The production process involves 11 press shops that segregate waste aluminium to be sent back into production, and is said to be 95% more efficient than the sourcing of primary aluminium.

Today’s figures illustrate how beneficial using reclaimed materials can be in car production, and come after the car maker has invested a total of £7 million into the process, with help from the UK’s Innovate fund.

JLR’s engineering director Nick Rogers said of the announcement: “Innovation is at the heart of everything we do at Jaguar Land Rover. We are driven by the desire to produce increasingly world-class, lightweight, vehicles, but we also want to be world leading in how we build them.

“The success so far marks a significant step towards our goal of having up to 75% recycled aluminium content in our vehicle body structures by 2020.”

As well as the XE, Jaguar also uses recycled aluminium in the bodyshells of its new Jaguar F-Pace and latest Jaguar XF.

Earlier today it was revealed that the car maker is closing in on a deal to absorb a 60-acre site located close to its Coventry base. The new site would allow JLR to expand its research and development facilities.

Video

Join the debate

Add your comment

.

Conversion

.

Thanks