Seven British companies have agreed to work together to develop prototype solid-state batteries, with the aim of making the UK a world-leader in an avenue seen as the “holy grail” of battery technology.

A memorandum of understanding has been signed by the Faraday Institution, the UK’s independent institute for electrochemical energy storage research,; EV battery maker Britishvolt; manufacturing equipment designing firm E+R; battery materials business Johnson Matthey; the UK Battery Industrialisation Centre; the University of Warwick's Warwick Manufacturing Group; and the University of Oxford.

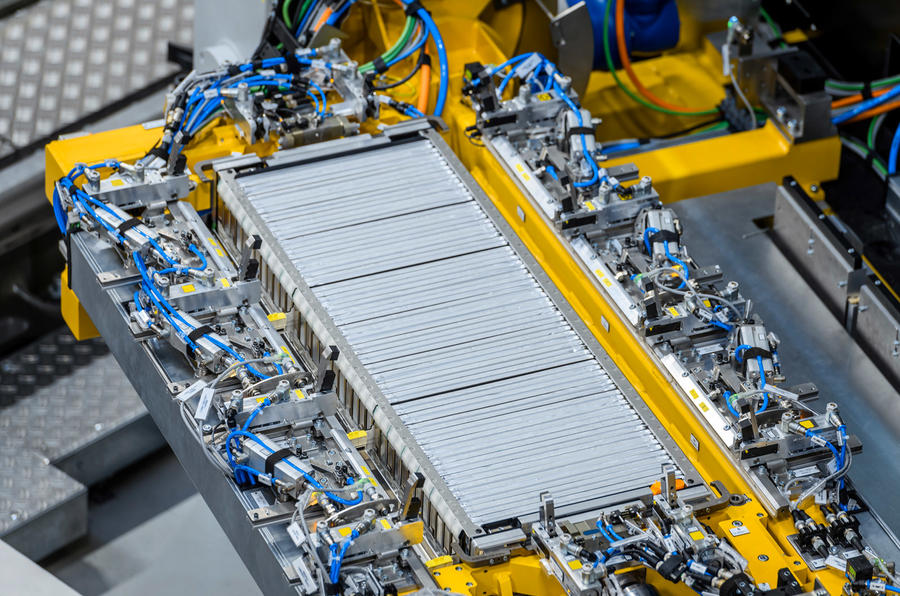

The group’s goal is to develop solid-state batteries that can be used in the automotive industry, where the potential ability to hold more charge per unit of volume than current lithium ion packs could dramatically increase the range of electric vehicles.

“I'm delighted to be able to announce the formation of this unique consortium for the advancement of solid-state battery prototyping that includes leading UK-based organisations at many stages in the value chain,” said Professor Pam Thomas, CEO of the Faraday Institution.

“Our leadership in this venture signals a move towards a role that the Faraday Institution will increasingly play as a trusted convener of significant partnerships between UK industry and academia as a route to commercialise breakthrough science emerging from our research programmes to maximise UK economic value.”

The Faraday Institution estimates that solid-state batteries will take a 7% share of the global consumer electronics market by 2030, as well as a 4% share of the EV battery market. By then, sales of solid-state batteries to car manufacturers could reach $8 billion, with a rapid rise predicted in the following decade.

Designs for a prototyping facility have already been drawn up by the consortium, although it's still searching for sources of funding. The facility would allow solid-state battery technology to emerge from university labs in the UK, with an ability to produce larger cells using scalable manufacturing techniques.

“Solid-state is the holy grail of battery solutions,” said Dr Allan Paterson, chief technology officer at Britishvolt. “Solid-state batteries have the potential to increase energy density significantly over battery technology available today and could dramatically and positively change the world of electric vehicles.

"Britishvolt will be at the forefront of commercialising this step change over the coming years.”

Join the debate

Add your comment

Just about every Add break on Tv is about how good there EV car is the best, but, they don't mention how much ( it's usually in small small print at the bottom of the screen) they will cost you, so, why shouldn't they be looking at better ways of powering transport?, what we're all driving today wasn't developed over ten years.

Good luck to them. It would also be good to see the Government offering up financial support for innovation. And it'll need more than the standard £30 million they typically provide for EV tech.

Solid state batteries could be revolutionary, but there is still so much unknown about them it isn't even a sure thing as to whether they're possible to produce at scale. I'd like to see someone with a working solid state call form first before announcing some lofty sales target in 10 years for a product that still doesn't exist.