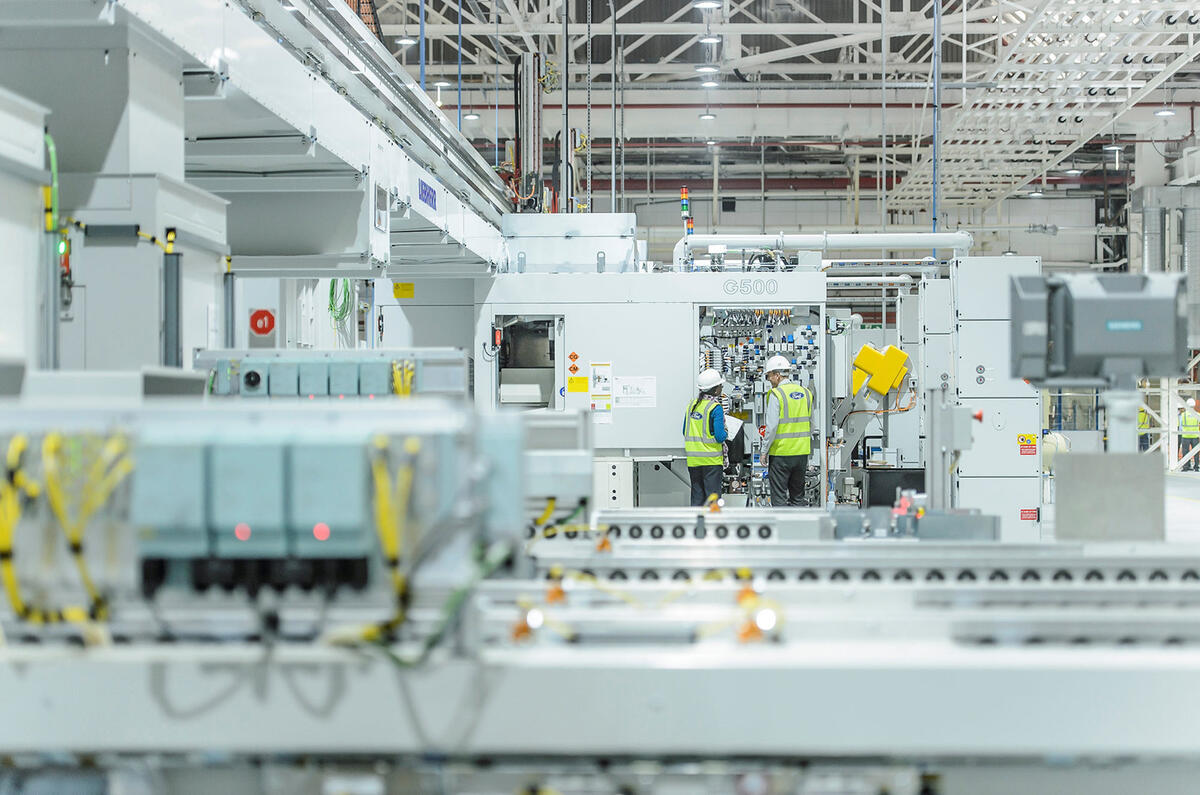

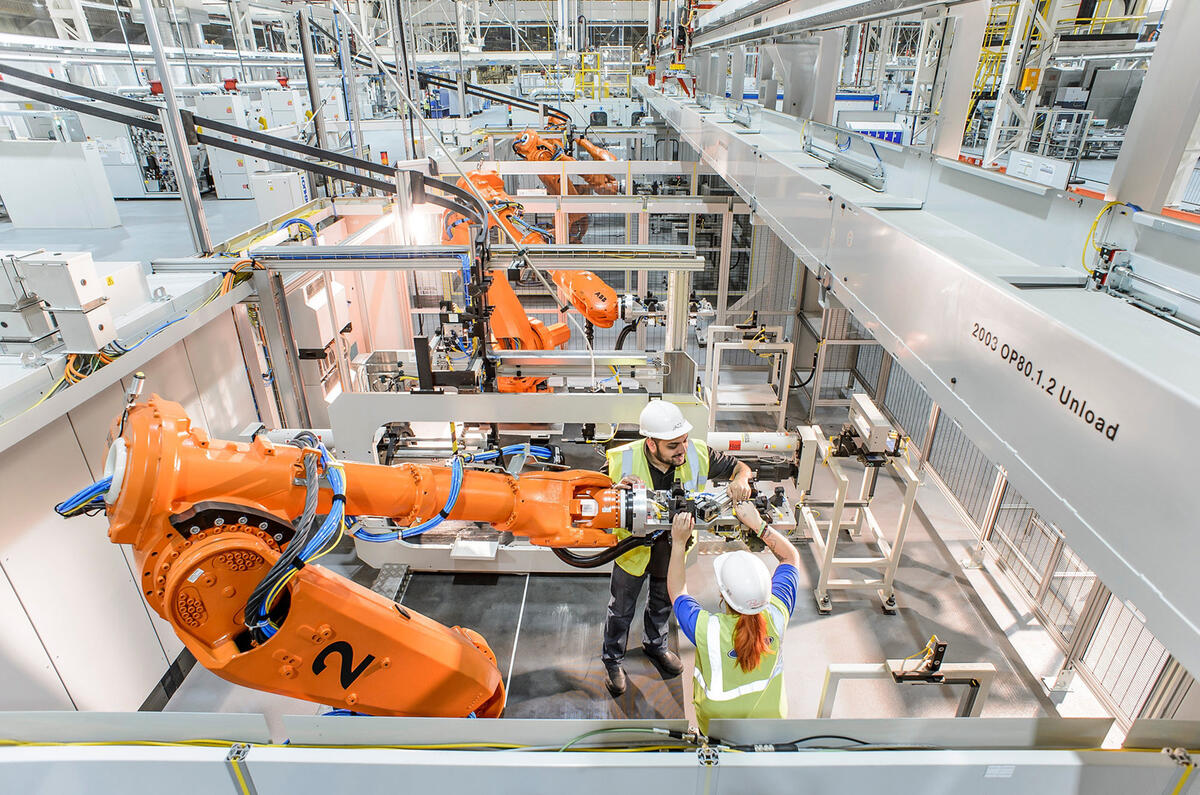

Ford has announced an additional investment of £190m at its Dagenham facility to produce a range of new 2.0-litre diesel engines for cars and commercial vehicles.

The development, which includes an £8.9m contribution from the Government’s Regional Growth Fund, will result in the creation of 318 new jobs related to the investment.

Today's announcement is the second part of a two-stage investment in the new engine programme. The original investment of £287m relates to the production of the engine that will find its way into Ford commercial vehicles around the globe.

The first of these engines will come off the line at the east London plant towards the end of next year. Production capacity will be up to 350,000 units per year and the first units will be powering Ford's vans in 2016.

Ford says the new engine will deliver dramatically lower Nitrogen Oxide (NOx) emissions and satisfy the air quality requirements of the proposed Ultra Low Emission Zone (ULEZ) that could come into force in London in 2020.

The new tranche of funding relates to the engine for passenger cars. Production is scheduled to start in 2017 – ramping up to a capacity of 150,000 units per year – with the first installation in Ford cars planned for 2018.

The new diesel engines have been designed and developed at Ford Dagenham and at the Ford Dunton Technical Centre in Essex.

Stephen Odell, Ford Executive Vice President for Europe, Middle East and Africa, said: “Ford is delighted to announce this next phase of investment at Dagenham. The overall investment of over £475 million, supported by the UK Government, underlines Ford’s commitment to the UK.

"This all-new, state-of-the-art, low carbon diesel engine has not only been designed and developed here, but it will be manufactured by Ford in the UK too. And it will be great for UK plc as these engines will be exported to markets around the world.”

Ford produces engines at two locations in the UK – petrol engines from Ford Bridgend in Wales and diesel engines at Ford Dagenham. Total production from the two plants exceeded 1.5 million powerplants in 2013.

Get the latest car news, reviews and galleries from Autocar direct to your inbox every week. Enter your email address below:

Add your comment

Hats off to Ford

So much for Brussels agreement to iron out inter-member trade imbalances.

But if you buy a car from JLR, Ford, a Juke or a Honda CR-V, Jazz or Civic, then it's made of a substantial number of UK-sourced parts and is the result of major infrastructural investment from India, USA and Japan.

I think the writing may be on the wall for Europe and the Germans.

Made in Dagenham

Given the world's continued love affair with German built cars and the vast number they sell, those walls will be written with invisible ink.

Absolutely. If we replace all the workers with immigrants who're willing to do the same job for half the wages, Ford can go on to make even greater profits. In fact why not do away with schools in Dagenham, send the kids in to work, make them work 16hr shifts, 7 days a week, no holiday or sick pay and pay them in loaves of bread. Bloody unions.

scotty5 wrote:If we replace

When did the autocar website turn into a UKIP convention?!

Immigrants don't need to move.

Sadly as British car plans, and especially in Linwood, were all going out on strike, while car plants in other countries were continuing to work and produce cars. Apparently in Germany it was less than a tenth of what the UK went out on. Rather than working as "them and us" other country's unions worked together to make the working environment better and to improve the product too. It's a lesson that the UK for the most part has learned. Except in Scotland with it's socialist governments and the SNP's attempts to stir up a class war (and I'm a Scot in Scotland saying that before the usual "English Tory" insult is thrown out by those nasty Yes voters).

pauld101 wrote:Strange, isn't

Doesn't BMW's Hams Hall plant manufacture engines for both Mini and BMW?

I also believe BMW have invested a large amount of money into the plant as well.

Great news!