Britain is about to have its very own Henry Ford of electric car propulsion, and his name is Ian Foley.

Through a combination of rare engineering insight, enthusiasm for electric machines even when they weren’t fashionable, clever planning and helpful semi-government finance (plus a helping of luck), Foley and his 20-man team at Equipmake in Hethel are preparing for a remarkable expansion that within five years could result in them manufacturing hundreds of thousands of electric motors in a brand-new Norfolk factory.

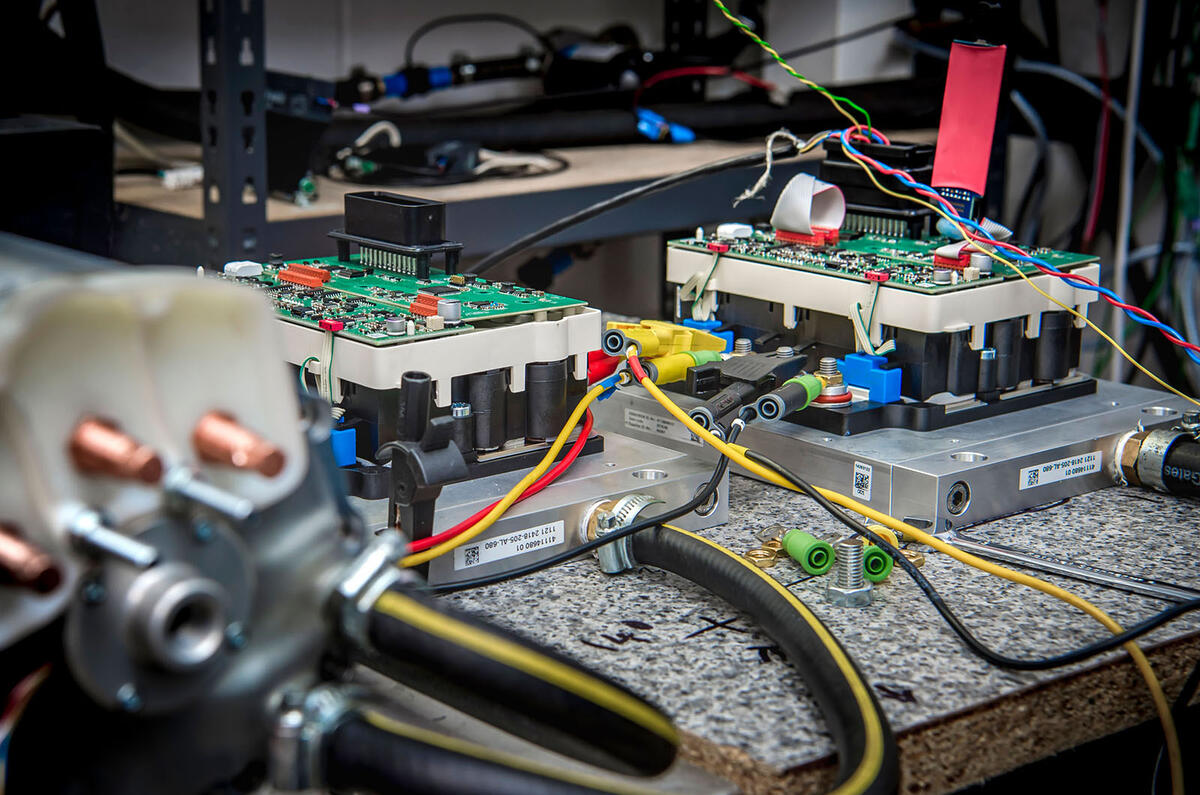

Already well known in race and road car tech circles, Foley and Equipmake have recently come to far wider notice as the designers, builders and suppliers of the four 295bhp APM200 electric motors and some of the power electronics that will propel the mighty 1180bhp four-wheel-drive Ariel Hipercar, a high performance range extender Equipmake is co-developing with Delta Motorsport and Ariel.

Though Foley is quick to acknowledge Hipercar’s value in spreading Equipmake’s name and skills, he’s also clear that the company’s aim is much larger than becoming a maker of engines for high-performance electric cars. A bus project and a second automotive customer project are already on the boil, and the number and quality of serious enquiries from giant automotive players is rising rapidly.

“Over the past couple of years,” says Foley, “the attitude of car companies to launching electric models has changed completely. I wouldn’t say they’re panicking, but many now feel an urgent need to get some sort of halo product out there on a very compressed timescale. Projects that might normally take four to five years are having to be done in two.

“Potential customers who feed their requirements for electric motors into Google tend to arrive sooner or later at our website. A gratifyingly large number seem to want exactly what we’re offering. We’re a risk for them, of course, in the sense that a big tier-one supplier making the right product might be better. But there simply isn’t a tier one with the right product.”

Join the debate

Add your comment

Well, yes, everything costs

Well, yes, everything costs energy, that's why ghosts can't exist. However, I think the cooling may be rather minor against the energy lost in power steering, etc. I always wonder why the energy created (changed) by the dampers and shocks can't be utilised, otherwise it's lost energy. It always seems such a waste. But then again, that's added weight, and the trend is to try and make a moving vehicle as light as possible.

Having watched the video

...let me (in part) explain why their design is good. It allows coolant to cool the magnets (to get right to them). This is very important as magnets lose some of their magnetic power as temperature rises (there's a graph). So if you get it hot, you lose performance, the motor would literally fail to turn. You can use high temperature magnets, but they are much more expensive - though they may already use them, I don't know. Keep the magnets cool and you have perfect performance from them.

Doesn't cooling cost energy?

It usually does in other settings. It's a question whether the quest is for maximum power or maximum energy efficiency. But efficiency is more about energy use vs. power produced, than absolute maximum power produced.

Well,

I would have thought that they'd use a central cooling system (as in a braking system) that uses an alternator. The alternator could even run mechanically - off of one wheel, so the faster the wheel turns, the more the alternator turns (on gearing). After all, you'd only need cooling when the motor is spinning, if the car was stationary then there'd be no need of cooling. Perhaps Equipmake could come on here and explain.

Looked at the wid

Evidently they employ water cooling - evidently the spoke design allows water jacks quite close to the magnets thus facilitating rapid cooling hence facilitating the magnets be run at max power more of the time, yet in any other setting familiar to me water cooling requires cooling radiator placed somewhere meaning drag and the need for cooling definitively means energy is wasted that isn't ultimately employed - the more the greater the need for cooling, combine that with the drag from a radiator placed somewhere. Most gains cost something along the way, the heat must be due to resistance somewhere -- they probably haven't yet cracked the problem of eliminating resistance without super cooling systems, thus the heat problem persists still thus inevitable energy loss through heat buildup.

I hope

...it stays British! SO many firms have started like this then sold out to a foreign company. The manufacture goes to an emergent nation and the jobs in the UK are resigned to 'design' or 'development'. My wife bought a fancy frying pan yesterday, costing a small fortune. It has 'British' all over it, but when you read closer you discover that's just the company. They don't say where it's made, but you can guess. They are quick to point out that it was 'designed' in britain.

I hope the UK government are doing as much as the EU will allow them to in helping Equipmake grow. The UK needs a manufacturing sector in new fields, like electrification. I was appalled that Ineos went to Germany for the development of their Defender-replacement when there's so much here in the UK (I own a small engineering business). There was no need for that other than getting it cheaper. And cheaper is never better! So ineos have already taken away a large chunk of its 'Britshness', and they haven't yet said where it will be built. The way it's going, it isn't going to be british at all, like Land Rover. Sorry to rant on, but we do NEED manufacturing for future generations here, as we seek new trading partners on good terms around the world (if we actually do ever leave the EU).

It’s juggling really....

How many Balls can you juggle?, this is no excuse for the current or future Governments, having to try and run the UK like a Business if you will can’t be easy, so many supervisors (read MP’s) some MP’s thrust into being head of this or that and being only as good as the last person doesn’t help, and the fact we had the Bankers (W?) kick the feet from under most of us and then Cameron shafted the Country by pushing for Brexit!, yes, if you had limitless funds then all our great innovators wouldn’t be forced to go outside the UK, and, yes the current Headless Chicken Government isn’t cant do a thing right,but, remember, we voted them in!

Without getting into politics!...

Cameron (a supreme idiot in my opinion) had to offer a referendum, or he actually could have lost MPs to Ukip. Although Ukip collpased after the referendum, remember that it was doing very well before it. Right-leaning MPs in the Conservatives were making noises that they'd jump ship if we didn't get promised a referendum - something I support, as I think we should have more (I believe in total democracy). Where Cameron went so wrong was in demanding so little from the EU to take back home. He should have made it plain that he'd accept nothing less than an end to Free Movement, or Brits would vote to leave. He would never have done that as he was a remainer. But even a remainer should have better-judged the mood of the country - god knows they employ enough advisors who conduct secret polls.

I have no problem with governments using taxpayer's money to 'help' emerging firms, especially when that help could mean more employment. In the past, taxpayer's money was used to KEEP employment, a different thing entirely. This was used in companies that were failing, whereas Equipmake has enormous potential. I expect Equipmake to be 49% floated in order to raise cash, and I expect lots of car firms will want to buy the shares. Or maybe a big-league player like VW will offer a lot of money for 49%. We'll see.