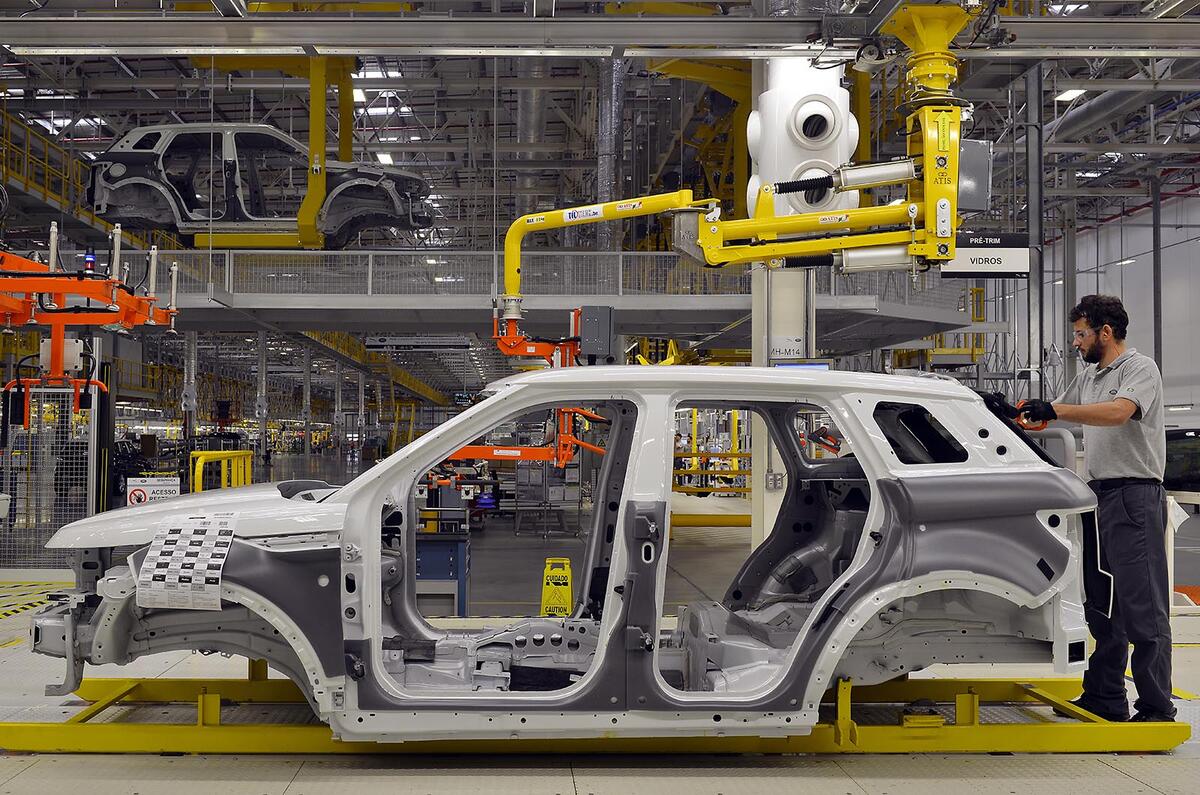

Jaguar Land Rover has opened a new manufacturing plant in Itatiaia, Brazil, which will produce up to 24,000 Range Rover Evoque and Discovery Sport models annually to be sold in the country.

As the car maker’s first wholly owned facility abroad, the factory will have a total investment of £240 million by 2020 and create 1000 jobs throughout the supply chain in Brazil, including just over 300 in the plant itself. There will also be 35 JLR dealerships.

The move by JLR reflects the brand’s importance in Brazil; Latin America is in its top 10 markets globally and it considers Brazil to be the most important. Land Rover is also the leading premium SUV brand in the country, accounting for a third of sales in the sector, according to JLR manufacturing boss Wolfgang Stadler.

Jaguar sales are also rapidly increasing in Brazil, and in the longer term it is possible that capacity at the plant could increase by introducing more shift patterns. Project manager for Brazil, Julian Hetherington, said: “Jaguar is coming from a small base in Brazil. In the longer term I think Jag will do very well [in Brazil] and then we’ll look at opportunities.”

He added that Brazil focused on smaller saloon cars, suggesting the Jaguar XE might be one prospective model to be built there, as well as the Jaguar F-Pace SUV. “The F-Pace is a more expensive product than XE, but I think it will do very well.”

This year JLR expects to produce up to 10,000 vehicles at the plant and will only carry out final assembly operation there. That means importing painted bodies from the UK as well as Ingenium diesel and petrol engines from its Wolverhampton manufacturing facility, with delivery times of seven to eight weeks. Hetherington added for every job in Brazil, in broad terms, there is one in the UK.

Alongside the Ingenium engines, the use of ethanol is also under investigation, because it has tax advantages in Brazil. “Ethanol is a big market want, especially in SUVs,” said Hetherington.

While many aspects of the cars are being imported, JLR has employed local suppliers for a number of elements including fuel tanks, glass, exhaust systems and interiors. “We’ve focused on the areas that are straightforward in the supply chain.”

When asked whether quality would suffer versus UK-built models, Hetherington said: “We always train to a fixed standard in all plants. We sent key people to UK to train them for standards, and we have a training facility in Brazil. We also use a world-class virtual training programme.”

He added that safety standards, which are notoriously bad in South America, are “exactly the same as in the UK”.

Brazil’s economy has taken a downturn since JLR committed to building the factory in 2014, but JLR says the premium market has held up well; its sales in 2016 have increased by 11%. The firm says it is “in it for the long term”.

Add your comment