A team of students has won the national James Dyson Award for designing a device that reduces tyre emissions.

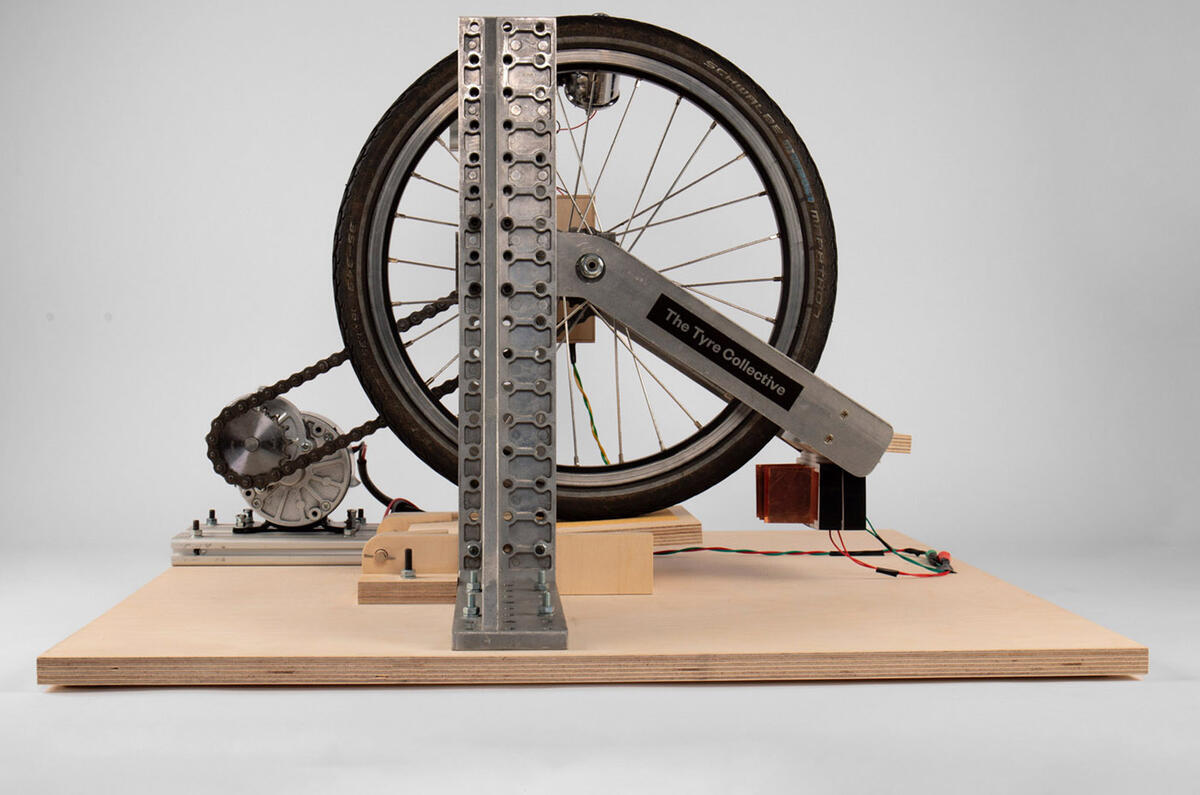

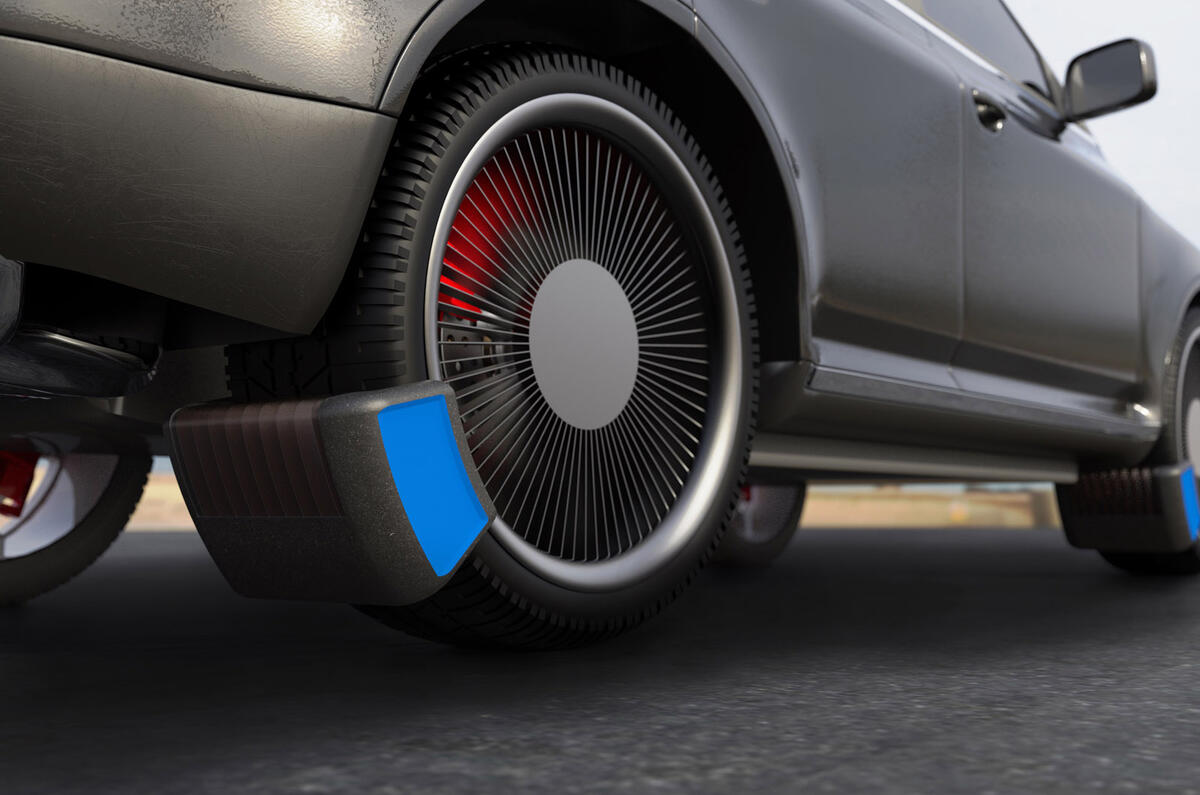

Created by Imperial College London and Royal College of Art students Siobhan Anderson, Hanson Cheng, Deepak Mallya and Hugo Richardson, the Tyre Collective uses electrostatics to collect particles as they're emitted from car tyres.

The team claims that the device, which is attached to the wheels, collects up to 60% of airborne particles from tyres - a significant reduction - by taking advantage of various airflows around a spinning wheel.

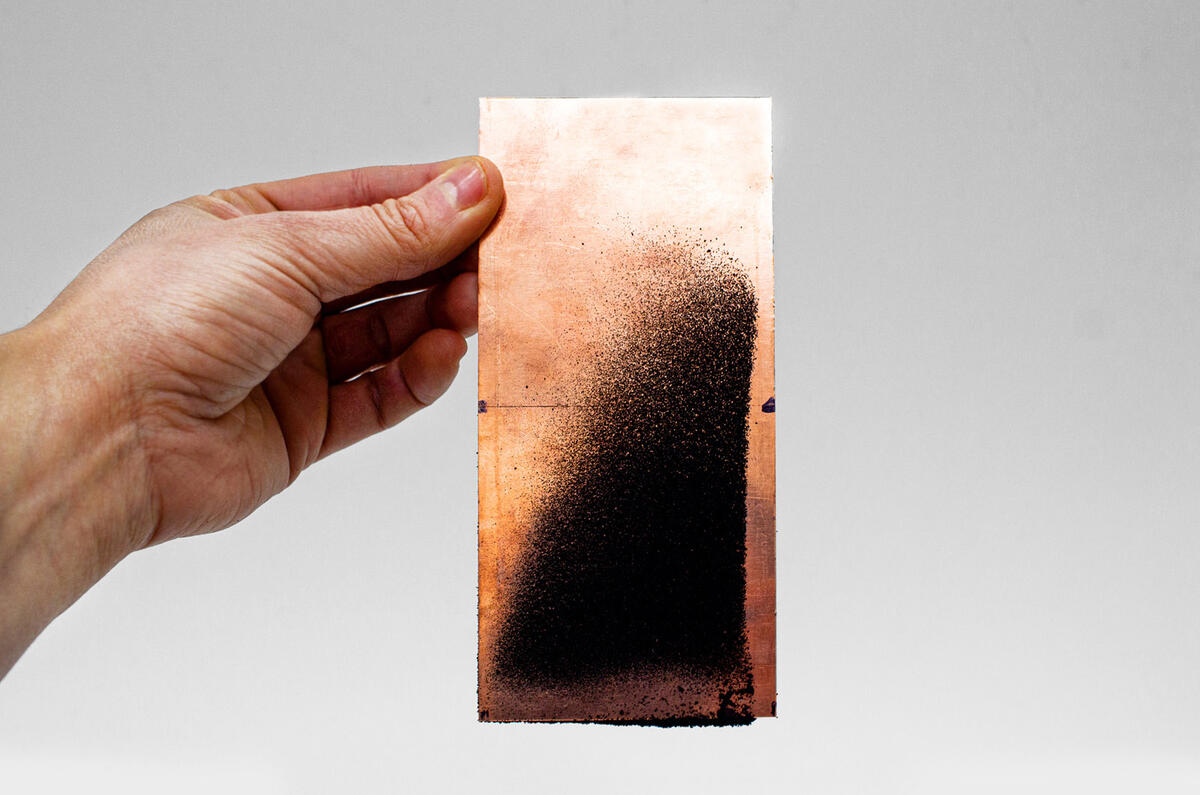

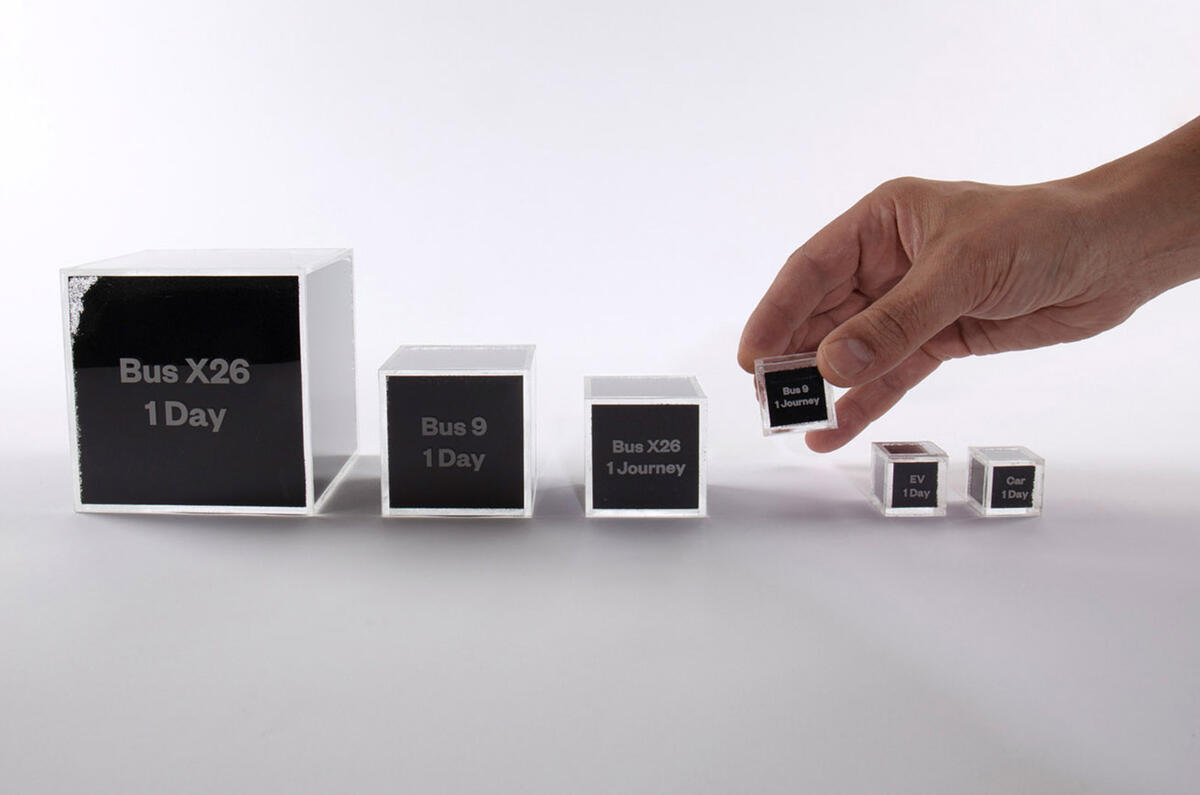

Tyre pollution is a mounting but relatively under-researched problem. Every time a car brakes, accelerates or turns a corner, tyre wear occurs, releasing particles that become airborne and can be breathed in, damaging human health.

Accounting for up to 50% of PM2.5 pollution from road transport, it's claimed, this kind of pollution can't be solved by electric vehicles. In fact, more people adopting EVs could actually cause tyre pollution to increase, since EVs tend to weigh more than traditional ICE cars due to heavy batteries.

Once captured, tyre particles can be recycled into new tyres or made into other materials, such as ink.

Circular Economy specialist and Dyson Award judge Sophie Thomas said: “We were unanimously drawn to The Tyre Collective for their creative innovation around this urgent issue of microplastic shedding from tyres.

“This collaborative, multidisciplinary team questioned and challenged, building an approach that demonstrates the crucial role of design and enquiry when we search for solutions to these global problems.”

As well as the James Dyson Award, the Tyre Collective team won £2000 of funding for their project. They will use this money to commercialise their invention in a sustainable way.

READ MORE

EXCLUSIVE: The inside story of the Dyson EV

Join the debate

Add your comment

The Mk1?

Seems a great idea, but I do hope it goes into production in a neater, less obvious way.

I think they might refine it a bit...

... before production. Great idea.

Bravo!

A clever Invention, let's hope it gets adopted my the Workds motor industry.