Nissan is currently developing a new type of fuel cell engine, which is powered by electricity generated from electrochemically reacting bioethanol and air.

The brand claims that the method of propulsion, which has until now been unexplored by mainstream car manufacturers, allows the generation of electricity with high efficiency. It's capable of powering a car to a similar range to conventionally-fuelled offerings: Nissan quotes more than 600km (373 miles).

Nissan says that when the engine reaches production, it will behave no differently to regular electric vehicles, despite its pioneering nature. This is in terms of noise, acceleration and power delivery. As with hydrogen fuel cell vehicles, Nissan’s bioethanol system emits only water.

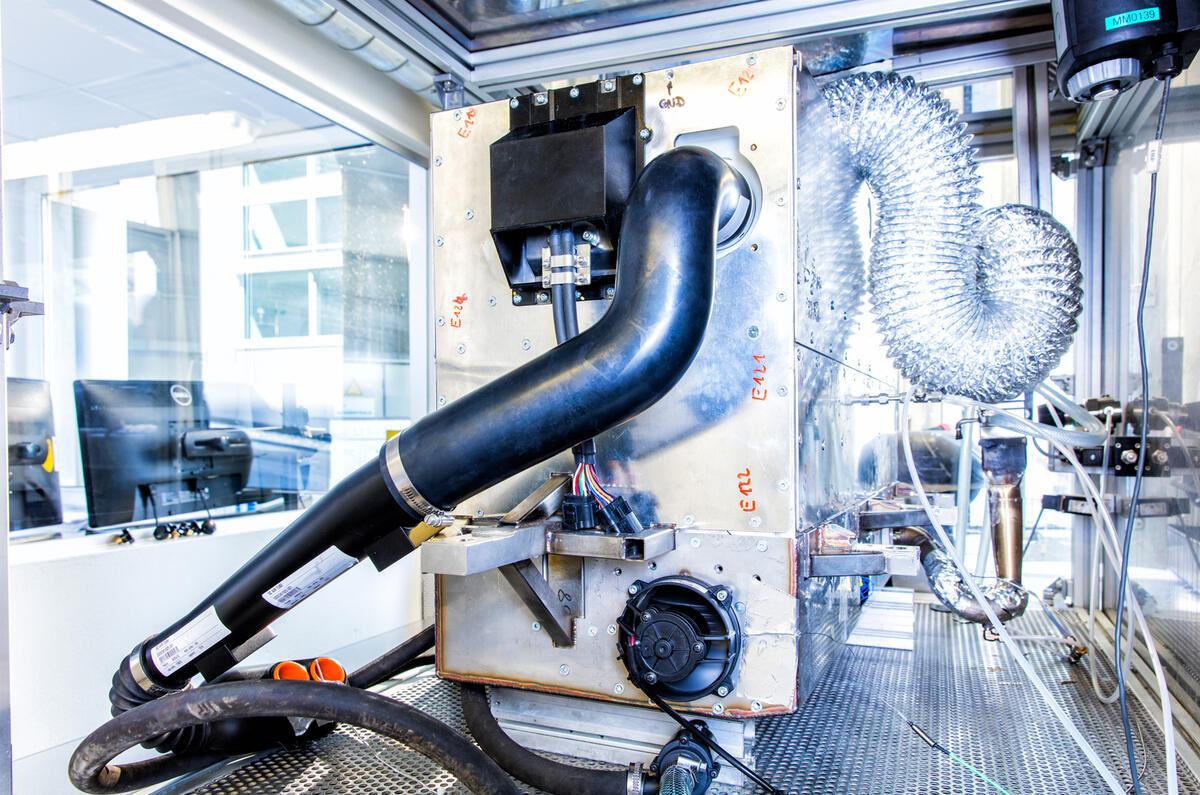

The engine uses a reformer to source hydrogen from bioethanol fuel, which powers the car through the solid oxide fuel cell. The bioethanol fuel will be sourced from sugarcane; an abundant crop in Asia, North and South America, which means the process of fuel production will produce very little CO2.

The localised nature of the sugar cane, and the high CO2 cost of transporting fuel means that markets close to the equator are the most likely to see the engine in commercial production first, although a Nissan spokesperson revealed that research and development of biomass-sourced bioethanol in areas without plentiful sources, such as Japan, is well underway. Additionally, projects to make ‘home brewed’ bioethanol made from garden waste are also under development.

Nissan hopes that the internal conversion of bioethanol into hydrogen will reduce the need for an extensive re-work of the current refueling infrastructure; a problem which is said to be holding back the progress of conventional hydrogen fuel cell vehicles.

Although the project is only in the early stages of development Nissan also promises ultra-low running costs akin to those of the current generation of electric vehicles. A short refueling time and other infrastructure benefits, including safer fuel (a 55:45 ethanol-blended water format) are also predicted by the Japanese manufacturer. Brazil and the United States’ current use of biofuels in their fuel infrastructure means that Nissan has high hopes for these countries’ adoption of the technology.

The project, which Nissan is developing alone despite its continued partnership with Renault, currently has no date for commercialisation. However, a Nissan spokesperson said: “the announcement will gather feedback and accelerate development.”

Join the debate

Add your comment

missing information

missing information

Nissan develops bioethanol electric engine