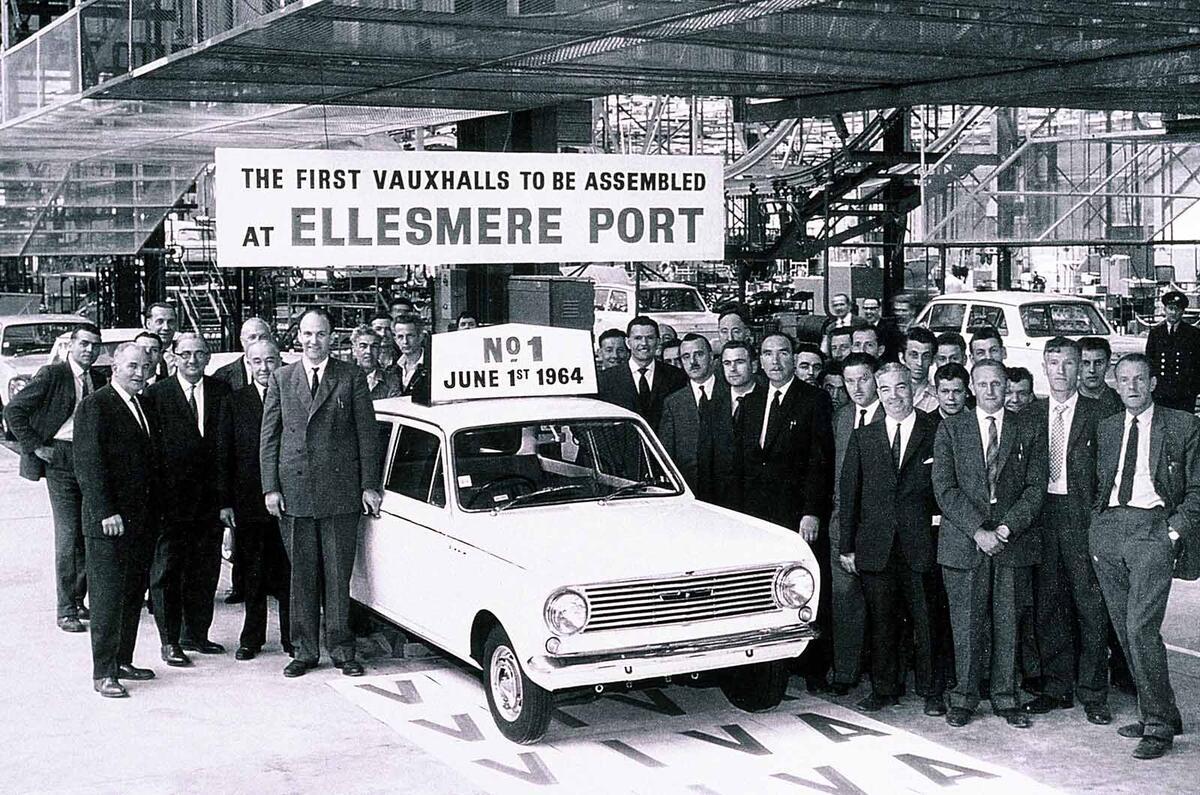

If there were ever a Lazarus of car plants, Vauxhall’s 50-year-old Ellesmere Port facility would surely take the title.

Twice in the past decade, the self-styled ‘Home of the Astra’, located on a 400-acre site just across the Mersey from Liverpool’s John Lennon Airport, has looked certain to close but has been saved at the last minute.

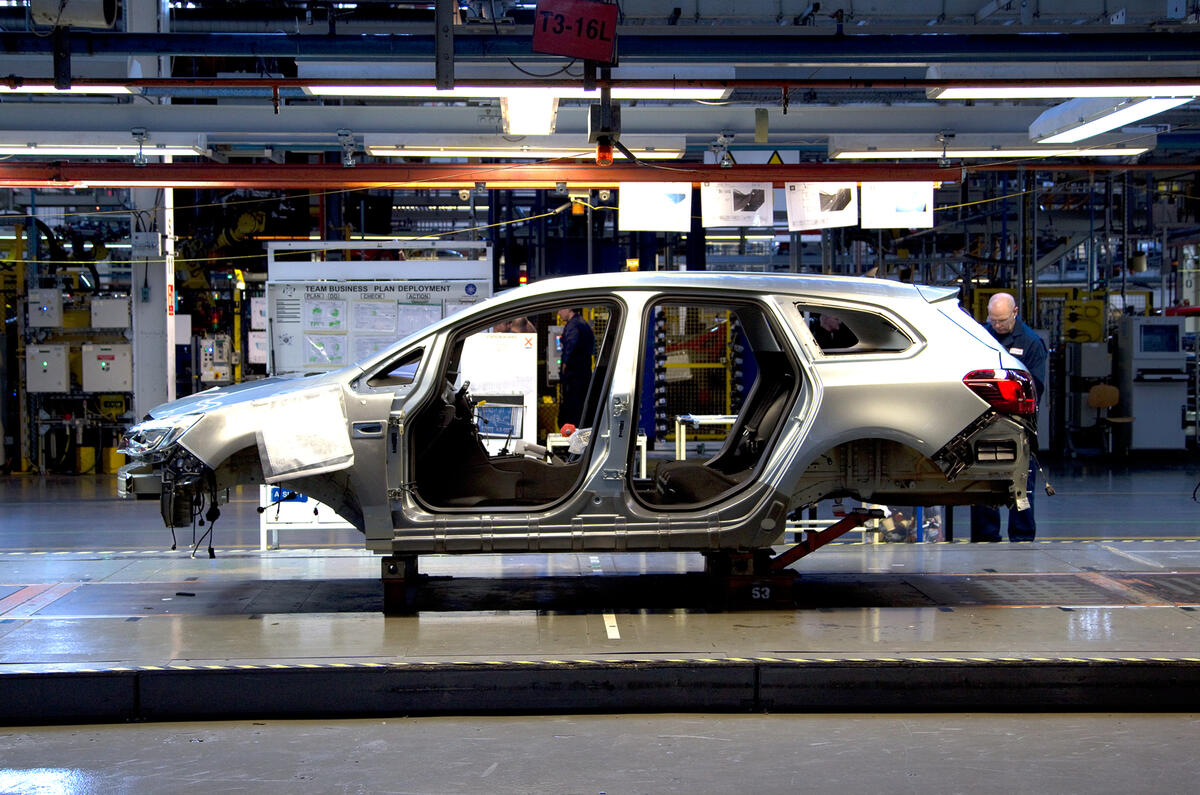

Today, according to insiders at Vauxhall’s parent company, General Motors, Ellesmere Port is more secure than ever, having just been chosen as lead plant for production of the seventh-generation Astra, due to begin in August 2015.

Plant boss Phil Millward, who started at Ellesmere Port as an engineering apprentice and has spent most of his 45-year career on Merseyside, attributes the latest transition to dramatic improvements in quality and efficiency that have flowed from a realisation that plants like Ellesmere Port must win “the global beauty contest”, challenging plants as far away as Australia and Korea. Ellesmere Port has modified its work practices and refined its production processes to win the 2015 Astra business from Germany’s Bochum plant.

“You’re always adapting,” explains Millward. “If you don’t, you’re bound to fail. Things have changed enormously in my time. We had 12,000 to 13,000 workers here in the beginning, whereas now we have fewer than 2000.

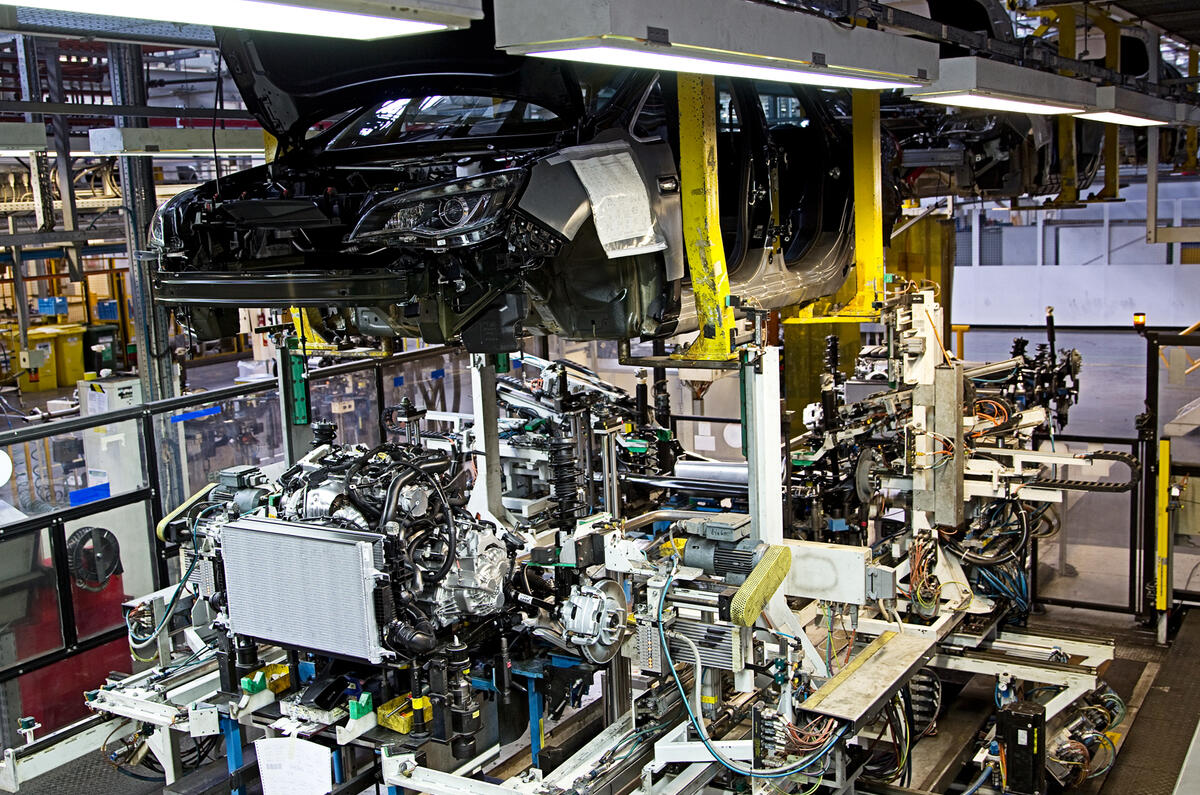

"Mind you, we used to build everything: engines, seats, axles, radiators and CKD kits for export. Now we have suppliers who make most of these things as sub-assemblies and deliver them ‘just in time’.”

The truth of this is visible just up the road; Ellesmere Port has an adjacent supplier park peppered with modern factories, with a busy flow of vehicles scurrying back and forth to the main plants.

Millward vividly remembers “the old days”, when Britain’s industry was riven by strikes and all negotiations were conducted in a ‘them and us’ atmosphere. “At times, it was like a war zone,” he recalls. “In those days, the unions were very strong. Was that helpful? Probably not. But much trouble flowed from the attitudes and behaviour of management, often provocative.”

A big part of the problem, says Millward, was the presumption on both sides of the argument – right up to the 1990s – that the market for British mainstream cars would always survive. “But the day came when they knew they were wrong,” he says.

The first crisis came in 2003-2004. GM had five European plants and needed four. The Japanese had been making inroads into car sales and demand for traditional bread-and-butter cars was giving away to MPVs, SUVs and smaller cars. The Astra conformed to none of these groups.

“Everyone’s money was on Ellesmere Port closing,” says Millward. “Our rivals on the European mainland presumed it would happen. We knew a dramatic move was needed if they were not to close us down, so we burned the midnight oil to devise changes that would convince top management it was worth sticking with us. Luckily, our rivals did very little on that score. The decision was close, but we won.”

However, the tough times weren’t going away. A couple of years into the new model’s life cycle, the effects of the global recession began to bite harder than any in modern times. Demand plummeted. Losses mounted.

Management was driven to implement, and labour to accept, one two-year wage freeze and then another. In 2010 GM filed for ‘Chapter 11’ bankruptcy protection in the US and then came up with a plan to sell its European manufacturing operation to a consortium led by components giant Magna. “I had spent a lot of time showing potential buyers around,” says Millward. “The sale looked a certainty.”

Halfway through 2010, out of the blue, the sale fell through, which most at GM considered great news, yet the crisis continued. However, bosses now felt that they had perfect licence to change anything that needed changing and close anything that needed closing.

Millward and a tiny team – working with a similarly small Unite team that included union veteran Tony Woodley – set out ways to ‘keep the lights on’ by convincing top management to agree that Ellesmere Port would build the seventh-generation Astra.

“I had a shopping list of things that needed changing and so did the union,” Millward explains. “At times we were pretty far apart, but we shared two desires: to keep the place running and make sure both sides benefited from the solutions. Again, our rivals were convinced we’d lose, which helped. They felt Ellesmere Port had been very lucky last time; it couldn’t be again.”

Today, the Port looks secure – and for a long time, because GM Europe has shut two plants since its days of serial over-production and depends on those that remain.

If current production is a little ‘off’ – 30 cars an hour against 47 at peak – it’s because the market knows the current Vauxhall Astra is nearing run-out.

Yet good times are beginning to roll. Millward and Co have almost certainly not faced their last difficulties, but these should be much smaller than the past tsunamis.

Join the debate

Add your comment

Pleased for you

You refer to it as 'Ellesmere

Article tweaked, so as not to

Ellesmere Port