Nissan has launched a dual-injector system designed to improve the efficiency of small petrol engines.

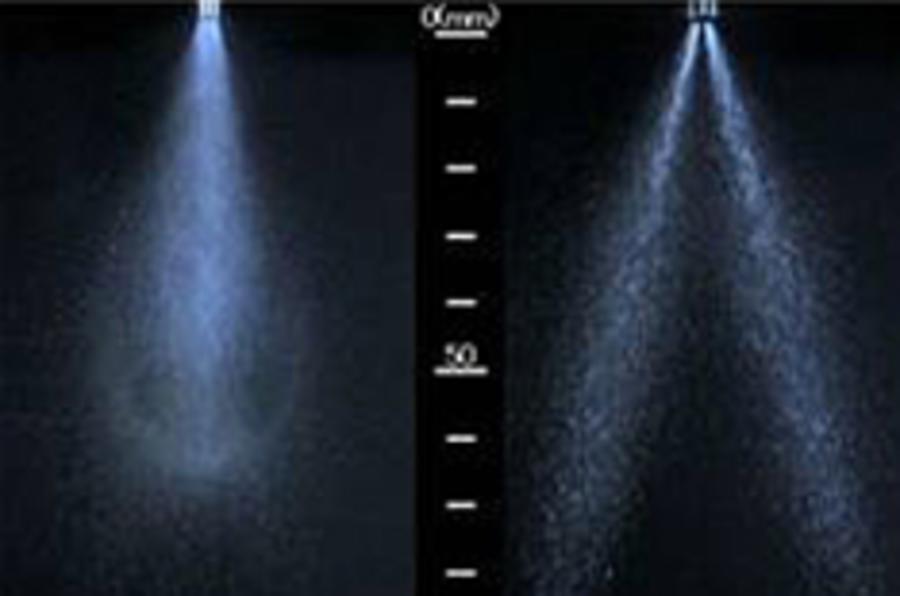

The new fuel injection system is the first of its kind in mass-produced engines. It uses an injector for each port rather than one for each cylinder, which speeds up fuel vaporisation, reducing the amount of unburnt fuel and reducing carbon emissions.

Twitter - follow autocar.co.uk

Most current petrol engines use one injector per cylinder, which furnishes fuel to two separate intake ports. The new Nissan dual-injector system doubles the number of injectors per cylinder, resulting in smoother and more efficient combustion.

Shuichi Nishimura, from Nissan’s powertrain engineering division, said, “We consider it important to further improve the fuel efficiency of gasoline engines as demand for gasoline and other internal combustion systems continues to increase around the world.

“By widely applying the dual-injector system on small-displacement engines, we hope to help reduce CO2 emissions and conserve rare metals.”

The technology is similar in theory to direct injection engines, which also inject fuel directly into cylinders. Such direct injection systems are difficult to use on small-displacement engines because they require a high-pressure pump that complicates design and pushes up development costs.

Nissan’s system is similar in efficiency to direct injection engines, but it can be produced at 40 per cent of the cost.

A Nissan source told Autocar that the technology would be introduced initially in Japan from 2010, with Europe set to get it in 2011.

Nissan will incorporate it into unnamed new models, but the source said it was also likely to feature on existing models to maximise the technology’s potential.

Add your comment