Hyundai is a serious contender when it comes to motorsport, we've gone behind the scenes to find out how they got there.

1. Find a base and set up your team

Hyundai Motorsport was created in late 2012 at Alzenau, near Frankfurt. Its headquarters is close to the Hyundai European HQ at Offenbach, the European Technical Centre at Russelsheim and Frankfurt Airport. The team entered its first WRC event, the Monte Carlo Rally, in January 2014 with three Hyundai i20s.

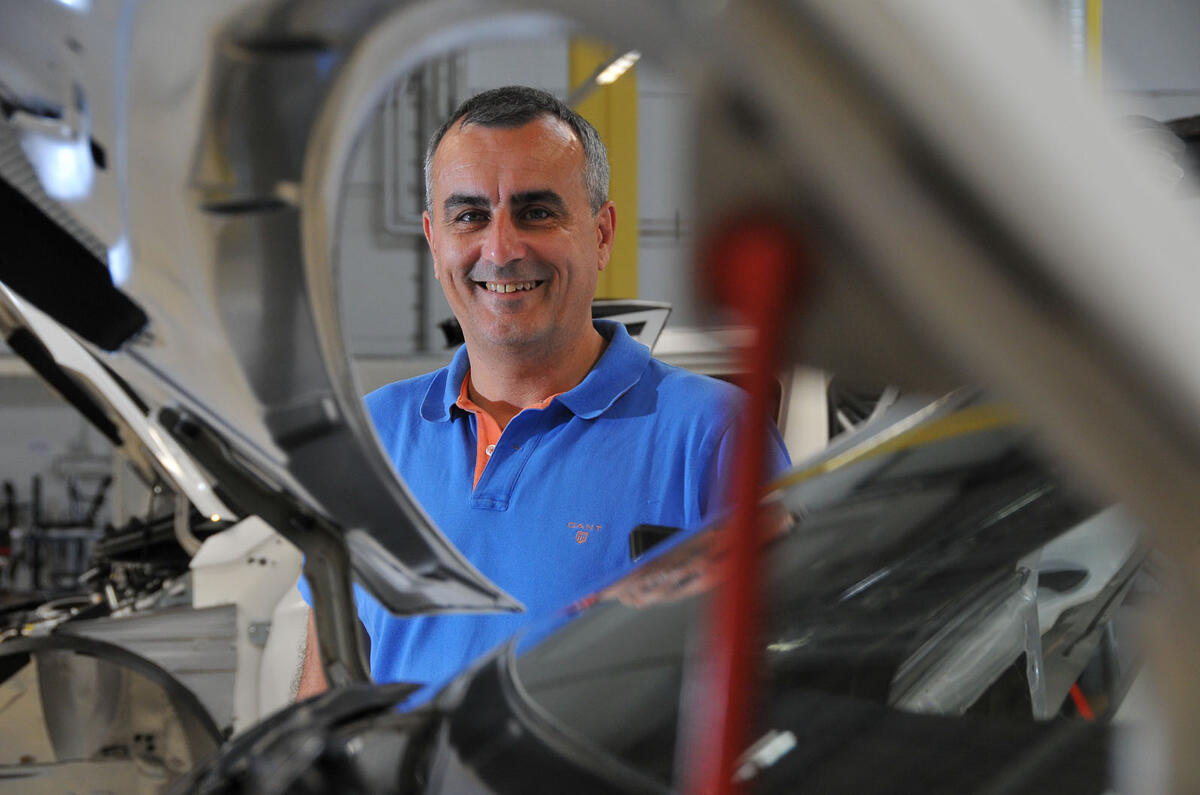

The first two seasons were a learning curve, despite a lucky win in the first year. This year, with the car fully developed, the team has won two rounds on pace alone. WRC veteran Michel Nandan was appointed team principal from the beginning.

“When we started, the factory was empty,” he says. “By the middle of 2013 we had 40 people, 100 by the end of the year. There are 200 today.” The first year focused on hiring experienced staff from endurance racing, F1 and rallying to design, engineer and run the cars.

“You need people with motorsport experience initially; it’s a different way of working compared to a normal production car environment,” adds Nandan. The i20 WRC car first turned a wheel in May 2013.

2. Establish close links with the parent company

When Hyundai last competed in the WRC with the Accent between 2000 and 2003, the running of the team was contracted out.

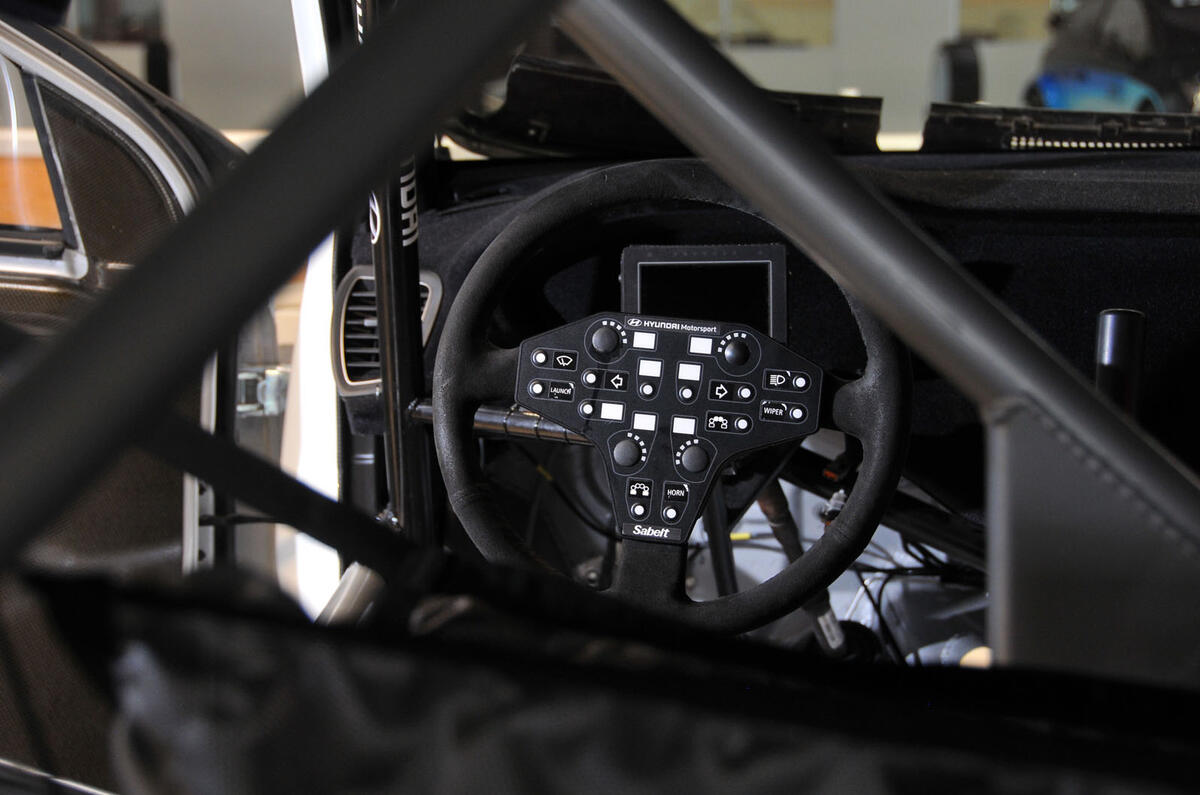

Now, Hyundai Motorsport is fully integrated, sharing learning and experience with the parent company. “The goal is to show what Hyundai is capable of and help promote future high-performance N road cars,” says Nandan. There’s an exchange of engineers between Hyundai Motor and Alzenau, and data gathered during the development of the 300bhp 1.6-litre WRC engine is fed back to the factory, along with information on new materials.

Add your comment