Technology that will halve EV charging times, without the need for any battery overhauls, is being primed for a roll-out by the middle of the decade.

MagLiB, which uses a magnetic field while charging batteries, could deliver “150-200 miles in under 10 minutes”, said Thomas Heenan, creator and CEO of start-up Gaussion.

The magnetic field is deployed via a pad connected to a power source, installed in the ground, in a similar way to a wireless phone charger. Because it can be used with any existing EV or charging system, it could transform the lives of EV drivers and reduce bottlenecks at charging stations if the technology were used across the public networks, he added.

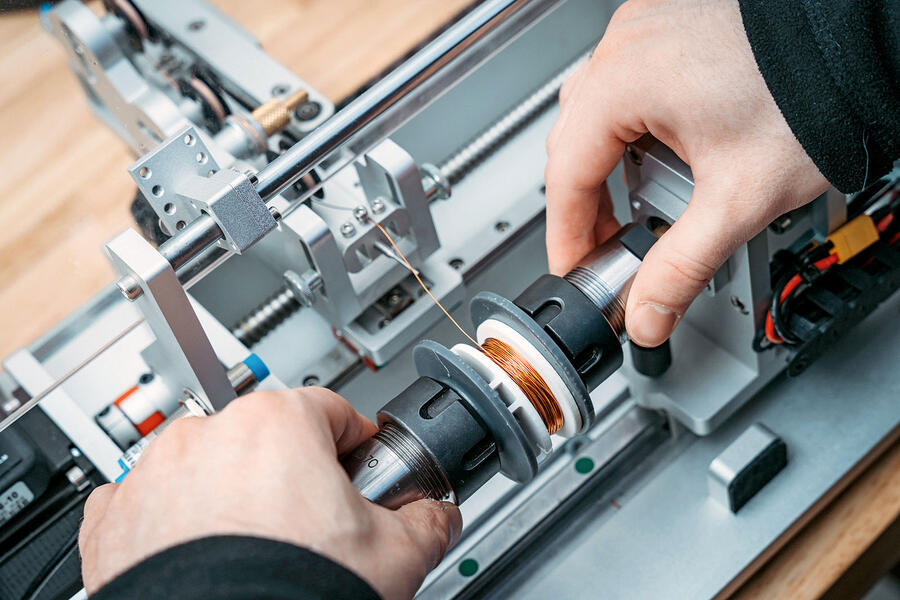

The technology works by externally subjecting a lithium ion battery to a specially designed magnetic field during charging. By doing so, the charging time can be substantially reduced without affecting the battery warranty.

Testing, which is at an advanced stage (first demonstration units will be ready in 2025), has already shown that battery life can actually be improved by using MagLiB during rapid charging.

Heenan said: “The lifetime of the battery will be the same or better using our technology and, in most cases, we’ve found it’s substantially improved.

“We took cells that are designed to charge from zero to 100% in an hour and charged them from 10% to 80% in less than 10 minutes. We did this 1000 times and they were only supposed to last for 300 cycles so we extended the lifetime substantially. In fact, we were nowhere near the limits and could have kept going.”

The power of the magnetic field it produces is relatively mild compared with something like the magnets in an EV’s drive motor and, said Heenan, “on a par with a household fridge magnet”.

Join the debate

Add your comment

The basic principal appears to be one of reducing the electrical resistance within Li-ion cells, using the specialised magnetic field. If this works as they say, reduced resistance within the cells should mean less heat is generated during fast charging, hence the ability to speed-up charging whilst also improving cell life. Less energy wasted as heat, should also mean improved efficiency during charging.

Apart from all the other vaporcoblers in this article, there is a.l big difference between having a working prototype by 2025 and "rolling out from the middle of the decade". Absolute clickbait shite.

Surely all EV batteries are contained within a steel enclosure which would screen them from any external magnetic field - so at the very least this would require a complete redesign of the battery enclosure?

And then there is the obvious consideration of where is the infrastructure to support such powerful chargers? At the moment we have newly installed chargers lying idle because the grid facilities are not able to cope.

Out of interest where are these newly installed charger lying idle because of the Grid, and how many are there?

I don't know about locations or numbers, but Shell recently reported 40 of its rapid EV chargers lying idle because it has not been able to secure grid connections. Maybe I was extrapolating a bit, but that suggests there may be many more...

So they're still in the construction phase then, and Shell spend millions but forgot about grid connection. Extrapolate a bit, no... more like just made it up.

For the rest of us, steel is a ferromagnetic material and therefore it does not "screen" the magnetic field, but becomes part of it.

Good luck next time, dude :)