A prototype of the Honda 0 Series SUV will be unveiled next month ahead of production starting in 2026.

To be showcased alongside the previously revealed Honda 0 Series Saloon prototype at CES in Las Vegas, the SUV is the second of seven planned 0 Series models that will arrive before the end of the decade.

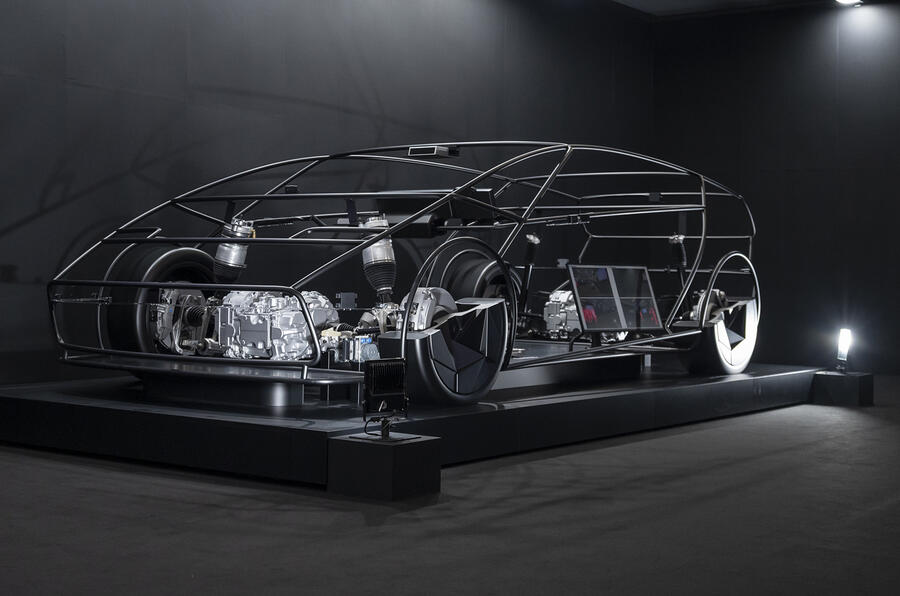

These futuristic-looking new-era Honda EVs will all sit on a new bespoke platform developed from a clean sheet of paper.

The first to arrive will be the saloon, which will offer around 482bhp and a range of more than 300 miles.

This will be followed in 2026 by the production version of the new SUV prototype, which is expected to be what Honda calls its mid-sized SUV. A smaller entry-level SUV and a larger range-topping SUV will join the line up shortly after.

By the end of the decade, a compact SUV, a small SUV and a smaller saloon are also due.

Honda 0 Series: powertrain, chassis and technology

The Japanese manufacturer has already revealed early technical details of the platform's capabilities at a special preview event, which included the chance to drive an Accord test mule fitted with a development version of the new powertrain.

The 0 Series Saloon will be offered with both single- and dual-motor powertrains, featuring newly developed compact e-axles that, Honda claims, can be mounted lower in the car, freeing up space and enabling the vehicle to have a smaller frontal area to improve aerodynamic efficiency.

The reduced size of the e-axle motors has been achieved in part by repositioning the inverter to make the units shorter. At least initially, 0 Series models will feature two different e-axle units in three different combinations.

Entry-level models will have a 241bhp motor on the rear axle and offer rear-wheel drive. There will also be two dual-motor, four-wheel-drive versions. The top-end models will use the same motor on the front axle, giving a system output of 482bhp (although Honda has yet to confirm if this will be the maximum output).

Join the debate

Add your comment

The only thing I can see this cars success is the animosity towards its shape, it's a bit too futuristic maybe?