GKN Automotive, a tier one supplier that has sold over a million of its eAxle electric axle systems, has announced that 13 more electrified models powered by its eDrive technology will soon go on sale.

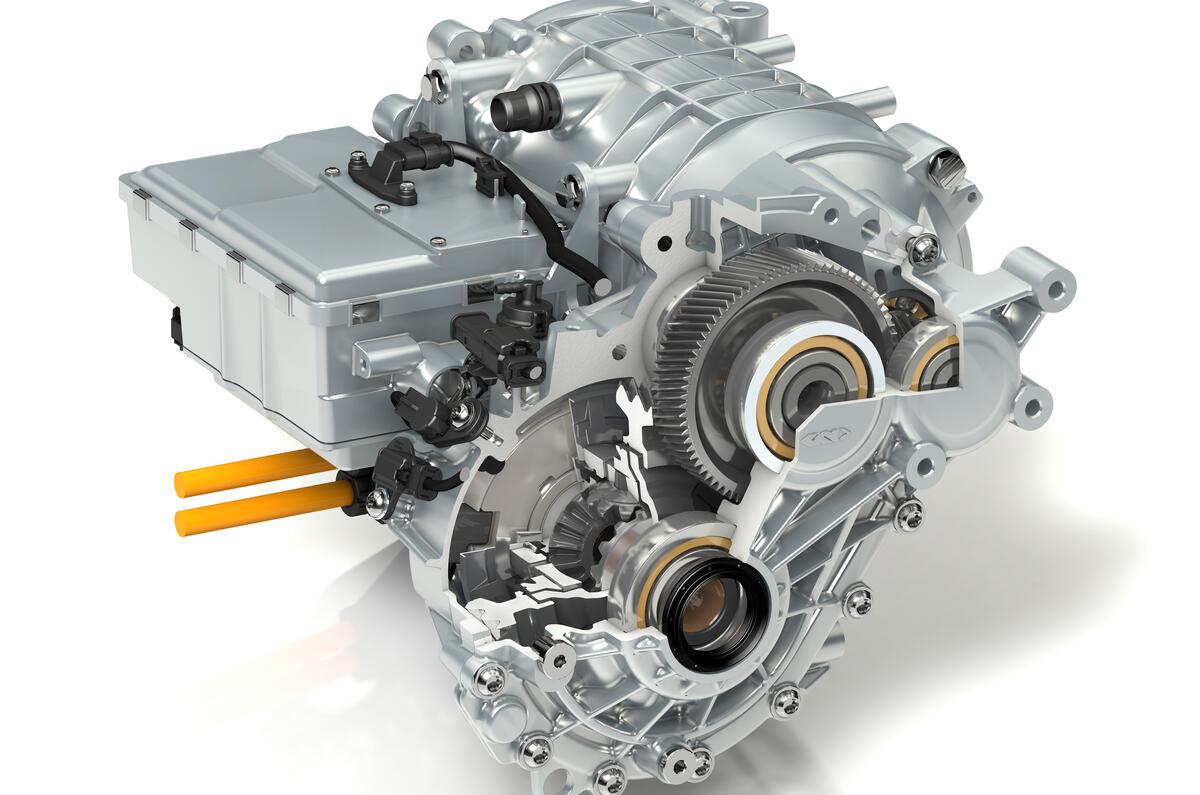

The models, from four global manufacturers, range from four-wheel-drive SUVs to a battery-electric city car. The powertrain line-up includes GKN’s three-in-one eDrive systems, which combine electric motor, transmission, inverters, software and control systems in one integrated unit.

GKN Automotive is known for its innovative driveline technology, including the Twinster all-wheel drive system, variations of which have been used in the Range Rover Evoque, Ford Focus RS and Vauxhall Insignia Country Tourer.

Now, though, says Dirk Kesselgruber, president ePowertrain at GKN Automotive, the industry is undergoing a significant change as it makes the transition to electrification. “The trend is moving away from the powertrain as a USP, and towards functionality and in-car experience. I think there will be a trend towards connectivity, automated driving functions and interior design. In most models, powertrain will no longer be the main differentiation element across different brands.”

The relative simplicity of an electric drivetrain compared to the complexity of a combustion engine and transmission means the role of driveline technology suppliers will change, according to Kesselgruber.

“Electrification is an opportunity to grow and we are investing in our engineering transformation," he said. "We’re shifting the skill set significantly from mainly mechanics to predominantly system software and electronics. We are expanding our workforce in Germany and in India, where we are opening a technical centre with Tata Tech in Bangalore to focus on software engineering but also to cover other engineering services.”

GKN’s electric drivetrain portfolio aims to cover all bases. Kesselgruber said: “We can supply any kind of transmission, and although the biggest emphasis will be on single-speed transmissions, we can add dual-speed transmissions at any time.”

It’s a similar story with electric drive motors and both permanent magnet synchronous machines and asynchronous induction machines (free of rare earth materials) are in the mix. GKN Automotive also has a systems team working with the Jaguar Formula E team in Oxfordshire, which, Kesselgruber says, provides valuable technology transfer from race to road. “The beauty of Formula E is that we are learning a lot about control strategies, the power electronics and the motor and many of these areas are relevant to the mainstream,” he said.

READ MORE:

UK firms join to develop "world-leading" EV powertrain

First drive: GKN eAWD Jeep Renegade BEV prototype

How to put an electric car on your driveway for as little as £900

Add your comment