The weight of lithium ion battery packs is one of the major drawbacks of electric vehicle technology, not just dynamically but also because lugging more weight around uses more energy. Since EVs are all about sustainability, that’s counterproductive. But what if the conventional battery could be ditched and replaced with an electrical storage battery technology that could be integrated into the car’s structural components and therefore add no additional weight to the car at all?

Scientists at the Chalmers University of Technology in Gothenburg and the KTH Royal Institute of Technology in Stockholm might have the answer in what they call massless energy storage.

The Swedes’ idea harks back to 1960s grand prix racing, when BRM and Lotus first used engine and transmissions as a structural part of the chassis, saving the weight of a traditional spaceframe. Massless energy storage is a modern equivalent, integrating lithium ion electrochemistry into a structural material from which a car can be made: carbonfibre composite.

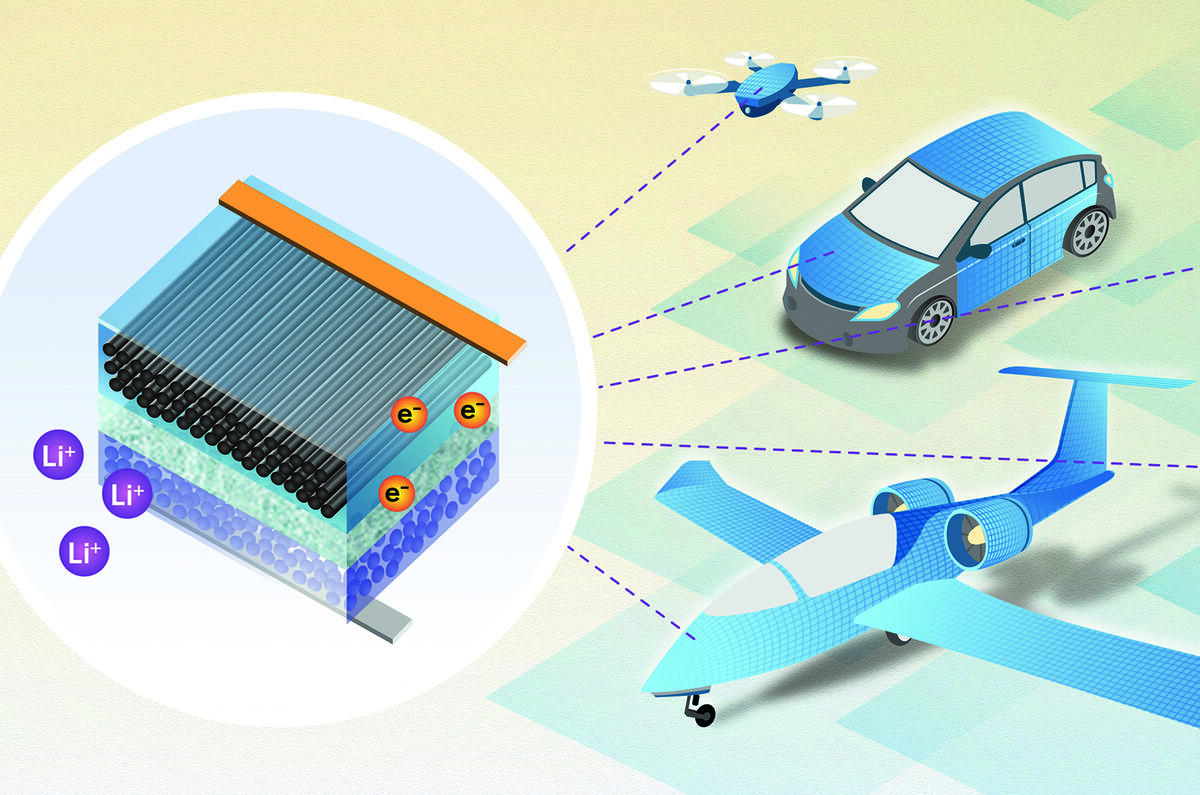

Existing lithium ion batteries have carbon negative electrodes (anodes) and metal-oxide positive electrodes (cathodes), both of which can absorb lithium ions as they migrate from one to the other through an electrolyte during charge and discharge.

The Swedish research project, which started back in 2007, has yielded a method of using carbonfibres to form an anode, with a cathode made from iron-phosphate-coated aluminium foil, separated by a glassfibre fabric in an electrolyte mix. A new concept replaces the foil with carbonfibre for the positive electrode and combines it with a thinner separator, therefore producing a stiffer energy-storage material that has the strength of aluminium but is lighter.

The research initially focused on the microstructure of carbonfibre. The scientists discovered that fibres with small and poorly oriented crystals have lower stiffness than fibres with large, well-oriented crystals but have good electrochemical properties, making them suitable anode and cathode material. The structural carbonfibre market is focused more on high-grade aircraft-spec material, but the slight decrease in stiffness isn’t a problem for use in cars.

Although promising, the new material doesn’t have as good energy density as a conventional battery. The first-stage version has an energy density by weight of 24Wh per kg (or 40Wh per kg for a complete battery pack), which is only 17% of the energy density of the Kia e-Niro’s 64kWh battery, for instance. However, losing a conventional battery of that size would shave around 460kg from the weight of the car and have a dramatic, favourable effect on range and performance.

Join the debate

Add your comment

Sounds expensive and impractical for a road car.

I watched a video the other day where an original Nissan Leaf had a battery swap. It seemed way too complicated when thinking of other devices that run on batteries and how they are replaced. I know it's a car with a powerful motor and other things to run from it, but basic plug and play techniques should surely be a good design consideration here (unless this is all about squeezing more money out of people rather than helping the environment)?

I think what would ease my reservations about buying an EV is that I could, at some point in the future, be able to easily upgrade the battery to a more advanced / cheaper / lighter / less environmentally demanding battery without having to change the entire car, or even be able to do it myself after buying the battery off the shelf!

You'd have to ensure that the car body wouldn't short circuit the cells in an accident and also if in an accident the cells might short circuit betweeen vehicles with battery bodies would lead to serious electrical fires, also in the rain or damp the area near the car could be at a high potential in relation to one or both of the vehicles involved in the accident so the rescue services would have to account for that. I can't see this idea being used in the near future on safety grounds. Vehicles could more easily electrocute the owner when or if the insulation breaks down or becomes faulty. It's a good idea that needs to be thought through properly otherwise bad things will happen.