A new, lightweight hydrogen engine concept from Israeli firm Aquarius Engines has been under development since 2014 and is close to maturity. Powered by hydrogen, the Aquarius Two Sided Free Piston Linear Engine (FPLE) is designed to generate electricity for plug-in series hybrids or range-extenders.

The tiny engine consists of a mere 20 components, only one of which moves. Although originally designed to burn petrol, it could conceivably operate on a variety of fuels including the latest ‘dropin’ carbon-neutral, synthetic liquid fuels, and a hydrogen version of the engine has been developed and tested. The Aquarius is called a linear engine, because instead of converting reciprocating forces into rotating forces via a crankshaft like a conventional piston engine, the single piston rod moves to and fro on a two-stroke cycle, firing on each stroke of the piston, at each end of the cylinder.

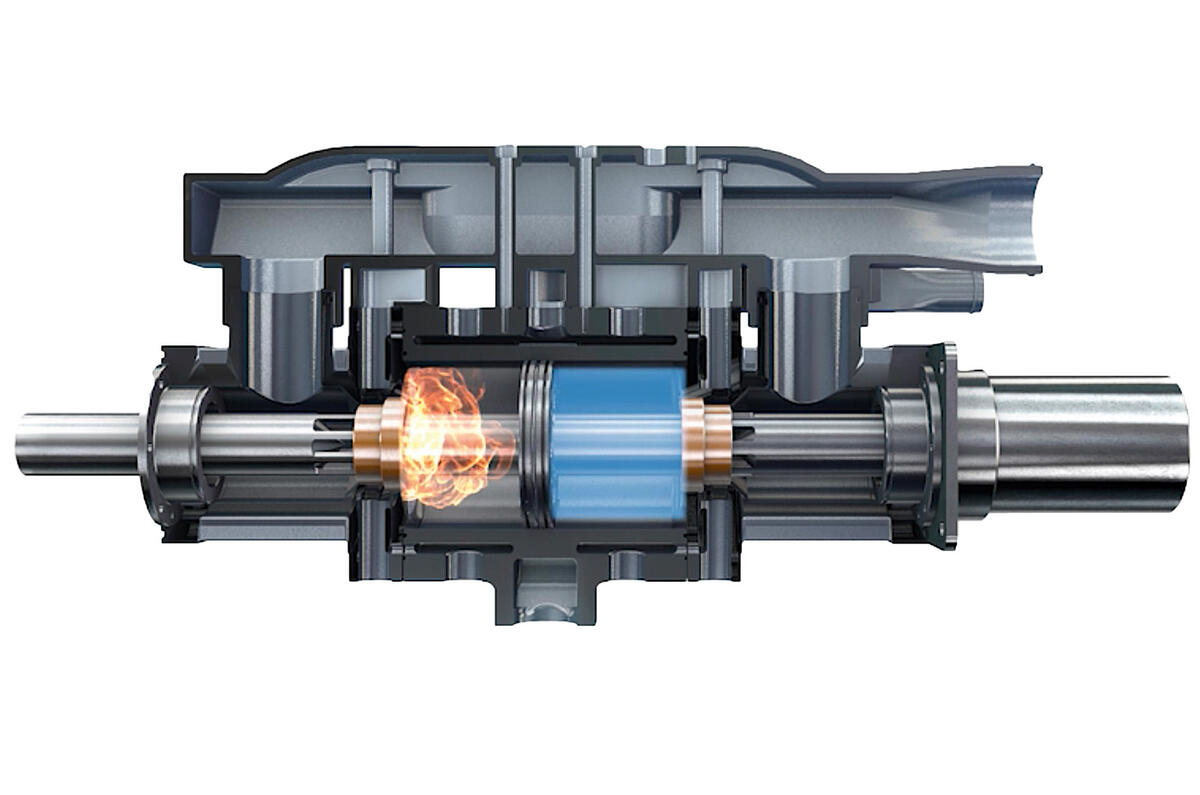

The Aquarius engine comprises one piston rod (a long bar with a piston at its mid-point); a small cylinder block in which the piston slides; two cylinder heads, one on each end of the block; two inner bearings and two outer bearings, which support the piston rod. The air-cooled engine needs no lubrication and instead has graphite piston rings and special coatings to reduce friction. The lack of oil rules out any chance of leaks or unburned hydrocarbons being produced during combustion and it simplifies servicing, which, its designers say, is minimal and required only every 1000 hours of operation. In that time, a hybrid car could comfortably travel more than 50,000 miles.

As the piston moves from side to side in the single cylinder, it expels exhaust via ports in the wall of the cylinder like a conventional two-stroke engine, then draws in air through a patented air filtration system and via ports in a hollow section of the piston rod. There are no poppet valves like a conventional engine or a highly stressed valvetrain to soak up energy in effort and friction.

There are four injectors in total, two in each cylinder head at each end of the engine. On each stroke, the hydrogen is injected into the fresh air by a pair of injectors, the mixture is compressed and ignited by a spark plug and the whole sequence begins again. A patented system of balance weights reduces noise and vibration.

The engine drives a generator that feeds the battery or traction motor of a series hybrid with electricity. Regenerative braking works in exactly the same way as with any all-electric or hybrid car, the traction motor switching to generator mode when the car slows to recover energy into the battery.

There are no production dates yet but a hydrogen-fuelled version of the engine has undergone independent testing by AVLSchrick in Austria and work continues on reducing noise levels from the electrical generator. Apart from hybrid cars, the engine is designed for use as a generator in telecommunications centres, microgrids, as an auxiliary power supply (APU) in large trucks, marine applications and for use in drones or APUs in aviation.

Join the debate

Add your comment

It's interesting to see the negative comments - all with reasonable objections - but this design is in its infancy. Give the firm and automotive industry time to prove the concept and then have a crack at them.

98% of hydrogen made today is made by methane reforming which produces CO2. Even if we get to a place where we have massive amounts of electricity from renewables electolysing water to make hydrogen is only 30% efficient. Then more energy has to be used to compress it, cool it and transport it to the point of use. Then when its burned the ICE engine is only 30% efficient and it produces NOx. Be careful about believeing what individuals with vested interests like Anthony Bamford are telling you about hydrogen. Its not the future.

LP in Brighton's comment about efficiency answers my question: why bother with fuel cells if, given an adequate supply of green hydrogen, we can burn it in these linear engines or a lightly modified regular petrol engine? JCB have stated that fuel cells are at the moment too delicate for use in heavy machinery, so in that case using hydrogen in an internal combustion engine would be appropriate. As always when it comes to all these established and emerging technologies, there's no single answer for every situation.