Beneath their often wildly futuristic bodies, today’s cars host technology that hasn’t changed much since the very early days - but manufacturers are seeking to change that with brake-by-wire systems.

Braking systems are an example of technology that has stayed largely the same for years: although not widely adopted until a little later, hydraulic brakes have been around since the turn of the 20th century. So: what is a brake-by-wire system?

What is a brake-by-wire system?

A brake-by-wire system controls the brakes of their car through the use of electricity, rather than a traditional hydraulic system. There is no mechanical connection between the driver and the car.

The idea was that electric calipers would do the braking and electric steering racks would enable fancy features such as enabling the car to take major avoiding action in emergency situations without ripping the driver’s thumbs off on the steering wheel spokes.

Ditching hydraulics and cleaning up and simplifying brake systems by moving to electronic actuation (so-called brake-by-wire) has been discussed for years, and there have been plenty of prototypes.

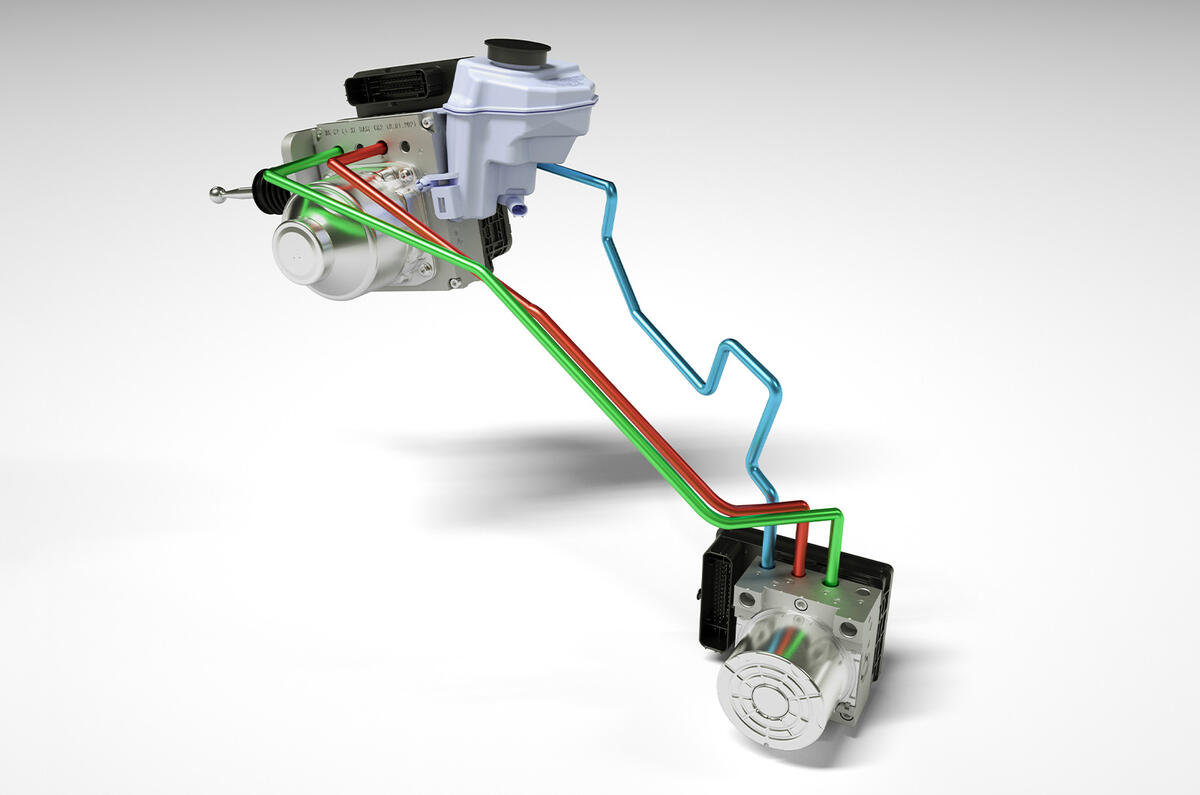

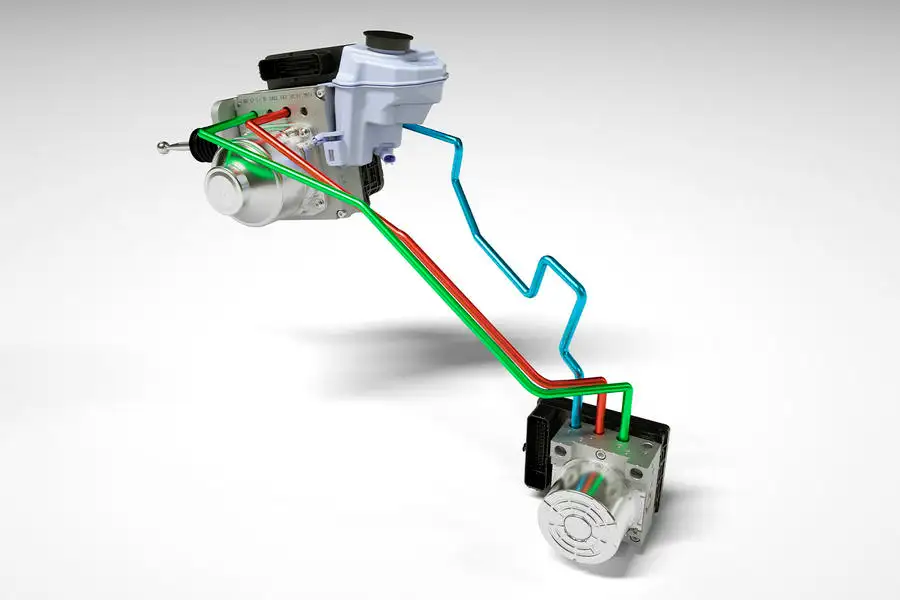

The first step towards it happening for real was Continental’s MKC1 system, which made its debut in 2018 on the Alfa Romeo Giulia and Alfa Romeo Stelvio, but that was just the beginning of the company’s plans for what it calls Future Brake Systems (FBS), which will lead to complete brake-by-wire systems.

The MKC1 system goes part of the way to full brake-by-wire but stops short of electric brake calipers. What it does do is integrate the tandem master brake cylinder (which generates the hydraulic pressure to apply the brakes), the brake booster, the ABS unit and the ESC unit, saving about 4kg.

Join the debate

Add your comment

The robotic charger sounds

The robotic charger sounds like a somewhat complex solution, the charge rate required for underground car parks are not high ergo an 11KW domestic charger that costs less than £1000 to purchase and install would suffice.

Installed at scale costs would be lower.

It would add probably less than 2% to the cost of parking.

Brake by wire

Surely one big plus of hydraulic brakes (especially dual circuit) it that you have fair warning of impending failure and fault finding away from a computer is not that difficult. The ABS installations have largely stuck to this principle by making the hydraulics continue to function when the ECU fails. Unless brake by wire is going to be akin to a three computer setup like an aircraft and a separate battery what will avoid an instant failure of the braking system .

Maybe a separate hydraulic system is required for back up

Autocar cannot publish this

Autocar cannot publish this sort of article, and simultaneously advocate driving go-karts for their purity.