Mercedes-Benz will always need to mine rare-earth materials to build electric car batteries, despite developments in battery recycling, according to the firm’s supply chain chief.

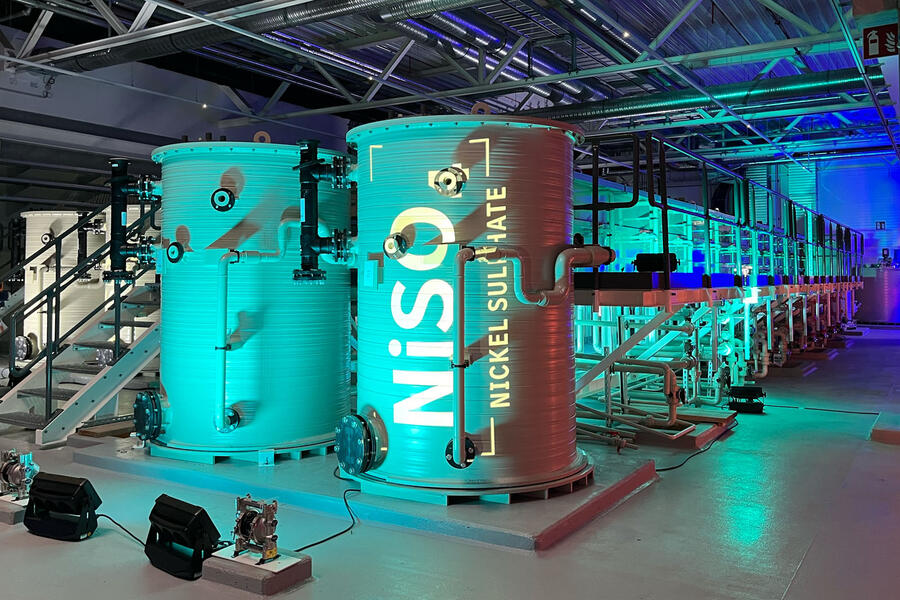

The company recently opened a new plant in Kuppenheim, Germany, that is said to be capable of recovering 96% of the raw materials from an existing EV’s battery pack. The plant will eventually yield 2500 tonnes of production-grade cobalt, copper, manganese, nickel and lithium a year – enough for around 5000 cars’ battery packs.

But Jörg Burzer, Mercedes board member for production, quality and supply chain management, has said battery recycling will never reach the point of total self-sufficiency. Burzer told Autocar: “I think we will always need 20%, 30% or 40% [of materials sourced using mining]. If recycling is in full swing somewhere in 2040, you still need a big portion of new materials coming from mines.”

This is despite the unusually high material recovery rate of the Kuppenheim plant. Its 96% is well above the 80% figure Mercedes claimed it would have achieved with traditional methods, such as smelting.

This is because Mercedes uses a hydrometallurgical process, in which an aqueous solution, rather than thermal energy, is used to separate the materials. The process takes around two days to complete and uses relatively little energy, with all power coming from a 350kW solar panel array on the Kuppenheim plant's roof.

The process starts by checking a battery’s state of charge before it is fed into a shredder. The resultant debris is run through a mechanical ‘washer’ – effectively a giant sieve – before it is separated by magnets, vacuum-dried and then put through a ‘filter press’, which works like a coffee press.

Join the debate

Add your comment

Hilarious that Autocar is now concerning itself with recycling. For decades it has happily promoted internal combustion cars, which are powered by petrol and diesel which is all dug up from the ground, can't be recycled at all and is just burnt in inefficient machines which cause massive amounts of pollution and CO2 emissions. Yet suddenly it's writing headlines that say 'shock-horror', not all future battery materials can come from recycling. Compared to the fossil fuel system, the mineral requirements of EVs are tiny.

This sounds like it creates a large amount of very toxic waste water. How is that 'cleaned'?

It's recycled like it has been for years. eg sulphuric acid ends up as fertizier, I sugest you look it up.

It's 'contaminated' rather than 'toxic' and the industrial processes are complex.