Porsche was in the news in August with a hydrogen engine project aimed at producing the high performance needed for its cars. Most of today’s research is focused on commercial vehicles, where less than 70bhp per litre is enough, but Porsche’s interest lies at the upper end of the scale and its subject is a virtual 4.4-litre V8 petrol, which at 590bhp is making 134bhp per litre.

Although hydrogen contains nearly four times more energy by weight than petrol, it’s a gas so its volumetric efficiency is a lot less. Used in a combustion engine, which in its purest, naturally aspirated form works largely on the basis of how much gas (air) it can ingest, hydrogen doesn’t stack up so well. Even stored in liquid form, with all of the challenges that entails, it still has to return to its gaseous state inside the engine.

The way around the problem is much the same as with a conventional engine: to boost the intake air pressure. Because the amount of fuel a petrol engine can burn depends on the quantity of oxygen it can draw in, pressurising the air intake with a compressor like a turbo or supercharger enables it to generate more power.

In the case of hydrogen gas, it’s a much steeper hill to climb. For Porsche to get the same power from its simulated V8 when it’s running on hydrogen instead of petrol, it needed turbochargers that perform well beyond the norm. It required boosting kit capable of delivering around twice the amount of air by weight of normal production petrol engine turbochargers.

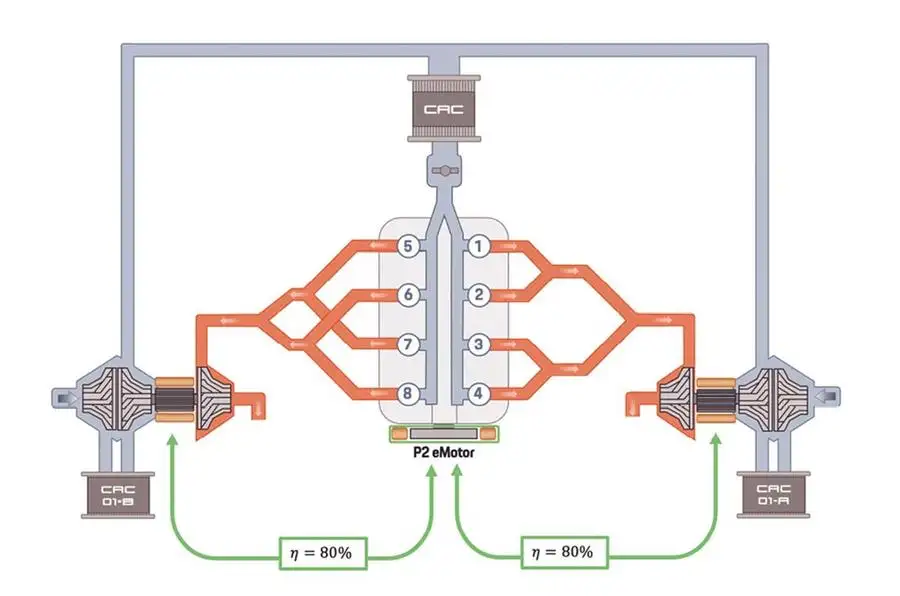

The answer lay in the type of technology used in Formula 1 and powerful electrically boosted turbochargers. But to find the right combination, the engineers simulated four different layouts using electrically assisted exhaust gas turbochargers (e-turbo) and separate e-compressors running on their own and independent of the exhaust system. The first was a parallel system using an e-turbo and e-compressor per cylinder bank. The second was a two-stage compression system with e-turbo and e-compressors running in tandem. The third used a pair of e-turbos, one for each bank, but with a guide vane system to increase efficiency. The fourth and chosen system (pictured) has one e-turbo per bank, each with dual compressors.

Although mechanically fairly simple, the route taken by the air is quite convoluted. Inlet air is pressurised by one compressor first, then passes through an intercooler, and then through the second compressor in a two-stage process. It’s neat and effective and Porsche says it managed to get “around” the same power in the virtual world as it did for the petrol version.

Installed in a virtual ‘reference’ vehicle weighing 2650kg, the hydrogen V8 achieved a lap time at the Nürburgring of 8min 20.2sec while returning emissions levels well below Euro 7 levels. Porsche hasn’t been specific about what the reference vehicle is based on but mysteriously neither it nor the 4.4-litre engine appears to be a direct match for any of its production cars.

Join the debate

Add your comment

Interesting but probably far too complex for your average/expensive for you average car owner.

Diesel is a kind of hydrogen, right?

That's fair enough, but this will be the first stellantis based car using the same architecture as the mokka and 208 etc which all get very good reviews, so I see no reason why this should be any different.

Copy here……………………………………….www.worksclick.com