What can you do in 32 minutes? Mow the lawn, perhaps, or make a carbonara? Maybe even squeeze in a couple of episodes of Friends if you skip the credits and fast-forward through the adverts.

If you’re one of the 600 people employed on Rolls-Royce’s Goodwood production line, you know exactly what you can achieve in 32 minutes.

That’s the ‘takt time’ afforded to each of the 42 production stations between the shutter door of the paint shop and the pre-delivery inspection pen, and meeting that rigid deadline – whatever your team’s specific task may be – 14 times per shift is utterly crucial to avoiding costly hold-ups and delays to the delivery of cars that have cost their VIP customers (who probably ordered around two years ago) an average of £440,000 each.

In reality, each station is allocated a rigid 28 minutes’ worth of work, with four minutes of contingency time built into the schedule at each stage to allow staff to sort out those rare tricky bolts and kinked wires.

Over the course of two daily shifts, the Goodwood line must paint, assemble, furnish and propel 28 entire cars, ready for inspection, road testing and finally shipping.

That’s small fry compared with the output of Toyota’s, Nissan’s and even Bentley’s UK factories, but remember: these are not normal cars. Instead, these are painstakingly specified celebrations of their owners’ personalities, and as such are referred to as ‘commissions’ rather than orders, each wildly different from the last and subject to post-production quality control processes that would make Nasa wince.

It is into this rigid, time-honoured framework that the new electric Rolls-Royce Spectre must slot, seamlessly, sensibly and with minimal concession to the somewhat glaringly obvious fact that it swaps Rolls’s mammoth 6.75-litre V12 for an electric motor at each end and a whopping 102kWh slab of lithium ion battery betwixt.

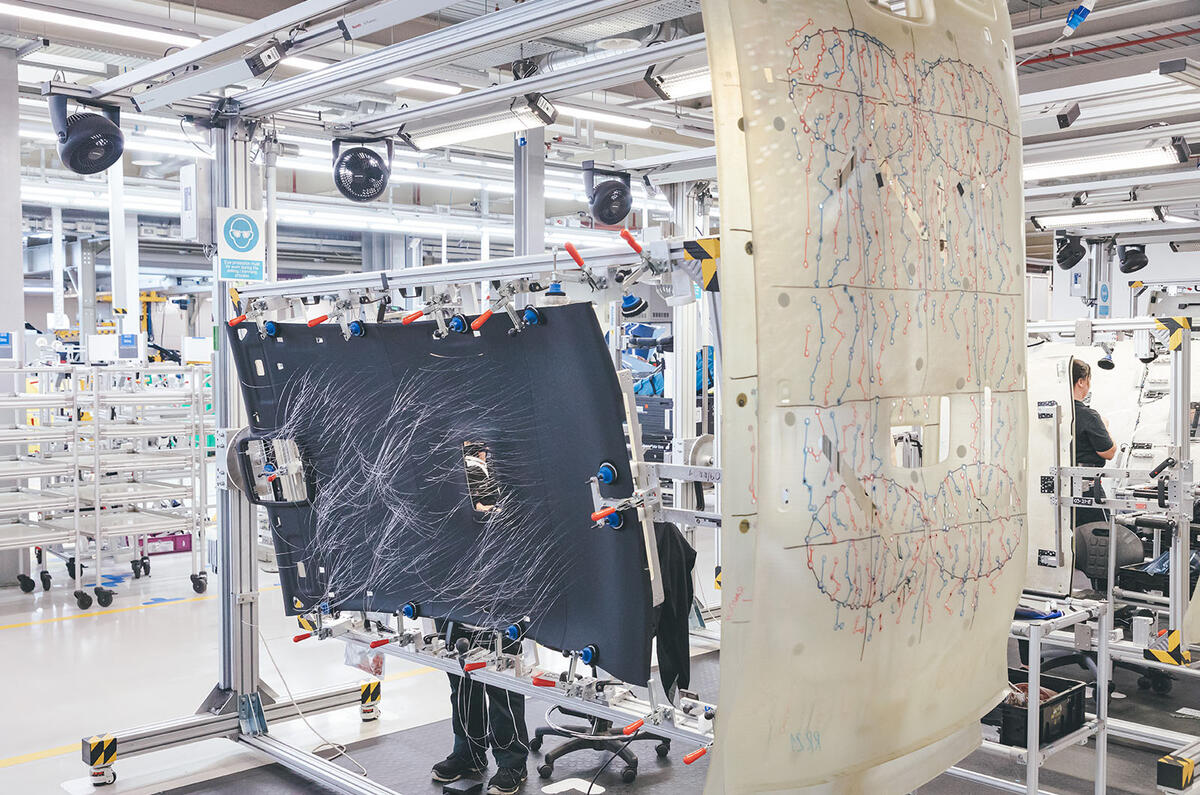

Compounding the complexity is that Rolls-Royce cars remain predominantly hand-built, with little scope for the simple reprogramming of robots and adjusting of conveyor belts.

That’s where Greg Denton comes in. As general manager for Rolls-Royce production, it is his daunting responsibility to ensure the system runs as smoothly as the priceless Audemars Piguet timepiece housed in the dashboard of the company’s £30 million Droptail roadster.

Join the debate

Add your comment

Sheesh...what happens when the battery on this puppy goes out in 10years and the tech is redundant? All RR's before this have 'stood' and 'exceeded' the test of time (in itself a sustainable quality). I'm struggling to see how this moves RR forward in this respect?

It might not be that the battery pack is an issue (for they have been proven and required to last more the ten years), but the software! As vehicles become more digitally integrated, the 20, 30 or 50 year old software may be so out of speck, it may present a problem having them out on the road. That said, RRs built in the 1920s, 30s, 40s and 50s, have a hard time keeping up with vehicles built today, so it’s not surprising. Maybe it might be easier to replace and update a 70 year old battery pack and OS?

It will probably be worth replacing and ugrading the battery and electronics on a car this expensive.