Nissan’s UK factory is primed to start production of the next-generation Leaf from March 2025 as part of a wide-reaching £2 billion transformation of the Sunderland plant.

Morphing from hatchback to crossover, as previewed by the Chill Out concept in 2021, the Leaf will be built alongside the Juke and Qashqai, as well as their pure-electric successors due in the coming years.

The current-generation Leaf ended production in March and work has already begun on incorporating a new battery installation station onto the production line (see picture below).

Production trials will start in August and run for six months. If all goes smoothly, the line will be ready to take its first Leaf models from as early as March next year, so the wraps are likely to come off the car towards the end of 2024.

The new EV battery installation station is being built onto the existing line

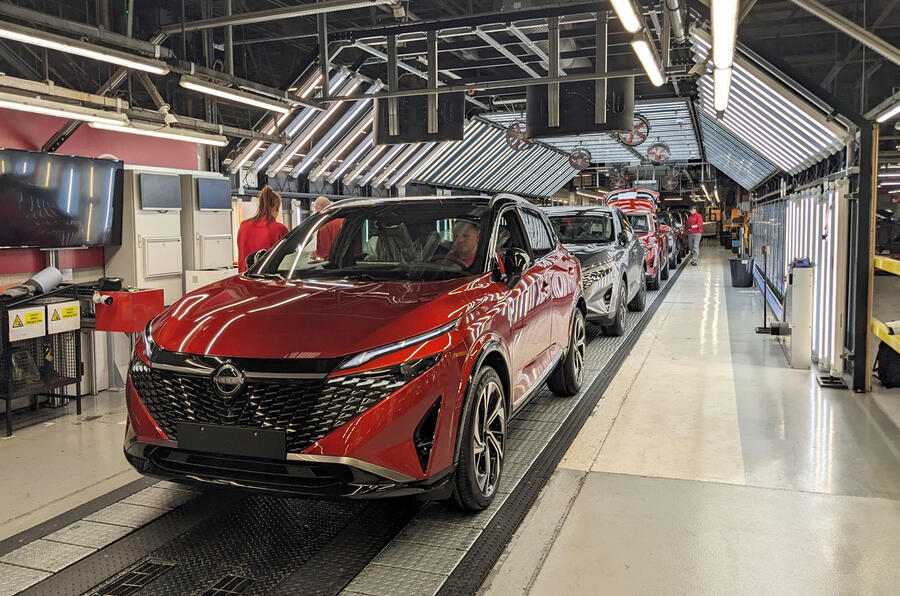

Nissan is investing heavily in the future of the Sunderland factory, where it has just started building the facelifted Nissan Qashqai, but its commitment to keep building cars in the UK is "not without its handicaps”, according to regional manufacturing boss Alan Johnson.

“We can just about justify continuing operations here, but it is not easy. It’s a real challenge,” he said, citing stringent cost-saving efforts – including a data-driven efficiency push – as a key factor in the factory’s ongoing viability, rather than local incentives.

He added that producing EVs in the UK “can work” but “only if all the stars align”.

“When it comes to competing against other countries, there are a fair number of handicaps in the UK,” he said.

Add your comment