Scrutinise the spec of an electric car and there’s a figure in miles per kilowatt hour (mpkWh) for vehicle energy efficiency, typically an average of between 3.0 and 4.0.

There’s no doubt efficiency is important, both for engineers, who use it as a yardstick of achievement, and for drivers, for whom it is the key to understanding battery range.

The next big efficiency race for EV makers is to be the first to achieve 5.0mpkWh. This figure is important because, for a typical 50kWh battery pack, the difference between 4.0mpkWh and 5.0mpkWh is 50 miles more range. So there’s a prize to be won.

And it won’t be long until the first 5.0mpkWh cars hit the roads. Indeed, in July, US-based Lucid claimed to be first to it with its Air Pure saloon, while a prototype of the upcoming Mercedes CLA recorded 5.2mpkWh.

It may seem like a relatively small incremental improvement, but it takes a lot to achieve it, from low-drag tyres to even using a different type of brake light. Here, we take a further look.

Aerodynamics

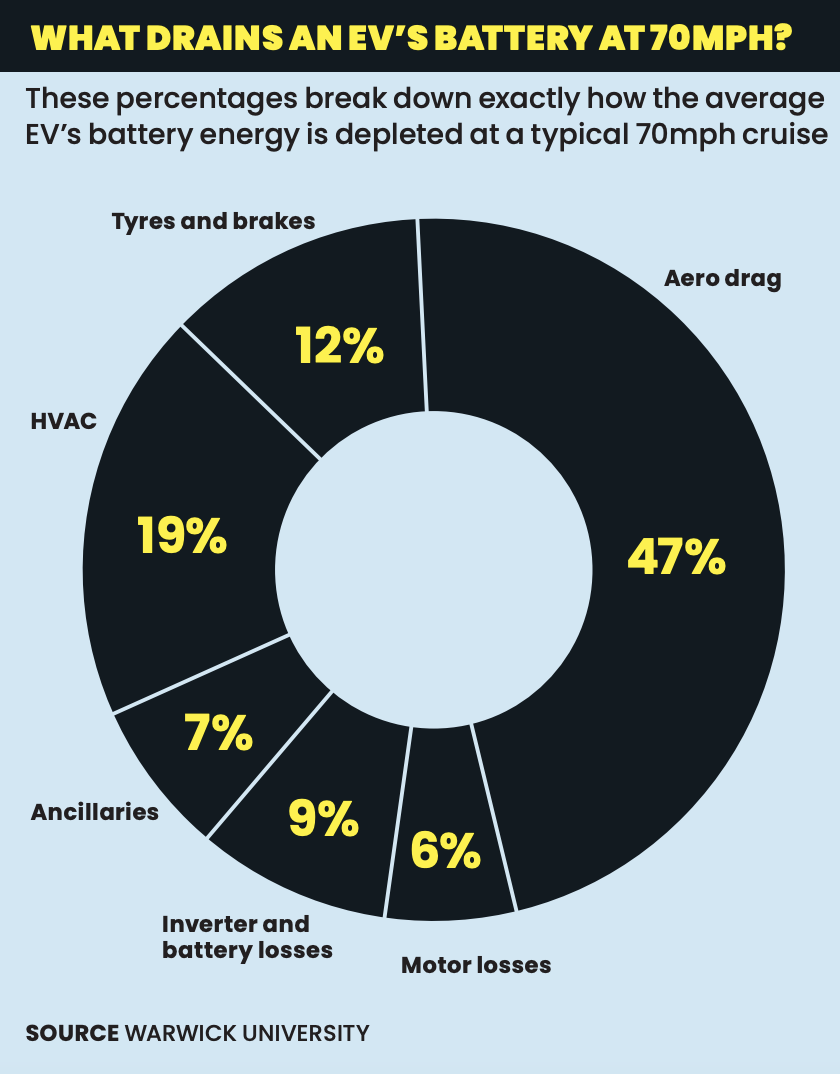

Reductions in aerodynamic drag will be the priority in the hunt for 5.0mpkWh. According to figures supplied by Warwick University, 47% of a battery’s energy is overcoming wind resistance at 70mph.

In practice, this means development budgets shifting to wind tunnels and sims, and designers reducing frontal area and honing details to reduce Cd (coefficient of drag).

Hyundai, for example, has prioritised low drag on the Ioniq 6 and achieved a 0.21 Cd.

The next stage will be costly but worthwhile, according to Professor David Greenwood of Warwick University: “Even a small reduction in the CdA [Cd and frontal area] has a significant impact on range at high speed, because drag power is proportional to the velocity cubed.”

Heating, ventilation and air conditioning (HVAC)

Right on the frontline of energy efficiency gains, HVAC contributes the second-biggest drain on the battery. “You really need to care about every watt used in an electric car, so parasitic losses have to be minimised,” says Greenwood.

HVAC accounts for 19% of battery output at cruising speed, but in extreme heat or cold it could reach 30%. Prioritising the heating of seats and the steering wheel, which draw just a few hundred watts, over full cabin condition, will help in the pursuit of a 5.0mpkWh goal.

But the real breakthrough will be a widespread fitment of heat pumps in place of traditional air-con units. They take about 1kW to run, one-third of a conventional aircon system, and can harvest waste heat from components, like motors.

Tesla and Volvo, for instance, fit heat pumps as standard to some models but they are expensive components. Polestar, for example, charges £900 for a climate pack including a heat pump. But the cost will fall as production ramps up.

Vehicle weight and battery regeneration

Weight contributes to tyre and brake losses, especially during city driving, but overall it has a smaller influence on energy consumption in an EV than in an ICE car, since energy is harvested during brake regeneration.

Greenwood says designers expect about 2% energy reduction for every 100kg saved in highway driving, while in city driving, where braking and regen are more common, the contribution of a 100kg saving is more like 5%.

Tyres and brakes

At motorway speed, tyre friction and drag between brake discs and pads draw around 12% of the battery’s power. But at city speeds, tyres and brakes replace aero as the biggest loss, reaching up to 50%.

So low-rolling-resistance tyres (such Michelin Pilot Sport EVs) are essential. Brake drag is being addressed with active management of the clearance between the pad and disc.

Lights and wipers

“We’re talking about reducing the power consumption of headlamps, windscreen wipers, blower fan, indicators and brake lamps,” says Greenwood.

Switching to an LED bulb in brake lights, for example, can save 1% in efficiency, particularly in stop-start traffic.

Marginal gains and test cycle

Jon Hall, head of research at Mahle Powertrain, emphasises that hitting 5.0mpkWh will depend on a series of marginal gains.

“It’s all about the reduction in parasitic losses, nibbling away at a lot of efficiency improvements and marginal gains,” he says.

But Mahle cautions that real-world efficiency can differ considerably from figures in the WLTP test. Air-conditioning systems, for example, are switched off in the test.

Batteries, inverter, power electronics and motor

Counterintuitively, advances in major electrical components won’t bring a significant improvement in overall efficiency. These electrical systems are already highly efficient (motors peak at 95% efficiency) and over a driving cycle are around 80% efficient.

“Car makers are spending money to gain 0.5% in the electrical system, but overall it’s a small contribution,” says Greenwood.

Longer term, maybe decades from now, Hall thinks solid-state batteries will increase efficiency because they operate at lower temperature.

Mahle says the introduction of AI self-driving should take account of efficiency, because these powerful computing systems can draw up to 5kW, about the same as an HVAC system, actually slowing progress towards 5.0mpkWh.

Greenwood concludes: “There is no magic bullet to hitting 5.0. We will need all of these things together.”

What actually drains an electric car's battery at 70mph?

Join the debate

Add your comment

This article claims self driving computers are using 5kW... I checked and a Tesla is about 70 watts in self drive mode. Please can we have some well researched articles.

Auto car seem to be consistently anti Tesla, so I can only assume are quietly funded by legacy automakers. This is a shame as it erodes my respect for a once great publication. So first off a correction on heat pumps, Tesla include them as standard on all new cars. Secondly a correction on efficiency, the latest Model 3 long range has a 75kWh battery and a 436 mile official range. My wife's 2023 model 3 dual motor with all season tyres did the circa 90 mile run from Garstang, up the M6 at 70 and across the A66 at 60 to Cockermouth achieving a 4.16 miles per kWh. So this included going over Shap and various other hills and finishing the journey at 500 feet above sea level. It was 5 degrees and the cars done 35,000 miles. It's also worth pointing out the Model S launched over a decade ago has a drag coefficient of 0.21. My point is 5 miles per kWh has already been achieved and strangely Autocar don't mention Tesla, but Tesla don't pay for advertising. As a side note my other vehicles are riteous gas guzzling monsters, but I've been surprised by just how capable EVs are... I was sceptical.

When autonomous driving comes along and each car knows where the other is.Then cars can shed lots of the reinforcing weight and that goes into protecting humans from themselves.