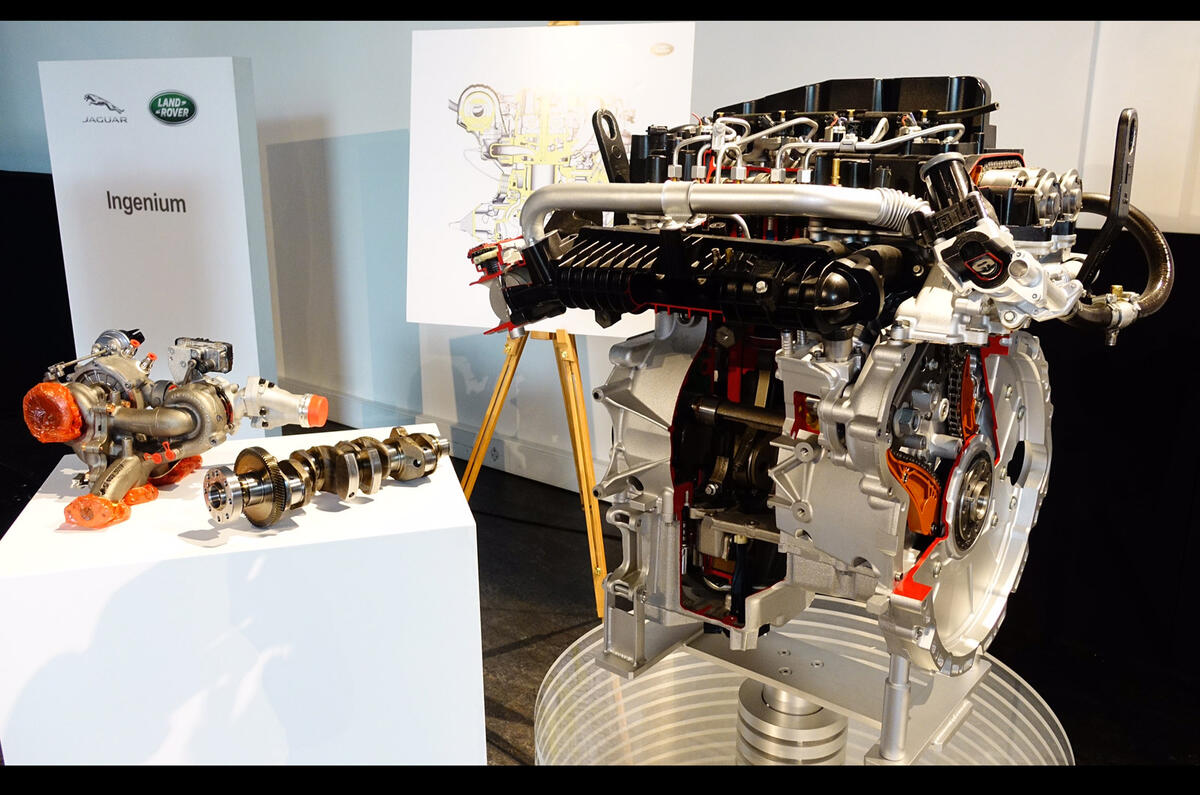

Jaguar Land Rover has revealed new details on its family of lightweight four-cylinder diesel and petrol engines, which will enter production in January 2015 and be fitted first into the Jaguar XE.

The new powertrain family weighs up to 80kg less than the firm's current engine offerings, while also improving performance and reducing CO2 emissions.

All engines in the range share the same bore, stroke and cylinder spacing, with each cylinder offering 500cc. JLR says the Ingenum family offers the "configurability and flexibility around which smaller or larger engines can quickly and efficiently be developed" in the future.

Autocar understands that a three-cylinder spin-off unit is a direct possibility and a straight six engine is ‘theoretically’ possible. The engine family can be used for front-drive, rear-drive and all-wheel drive.

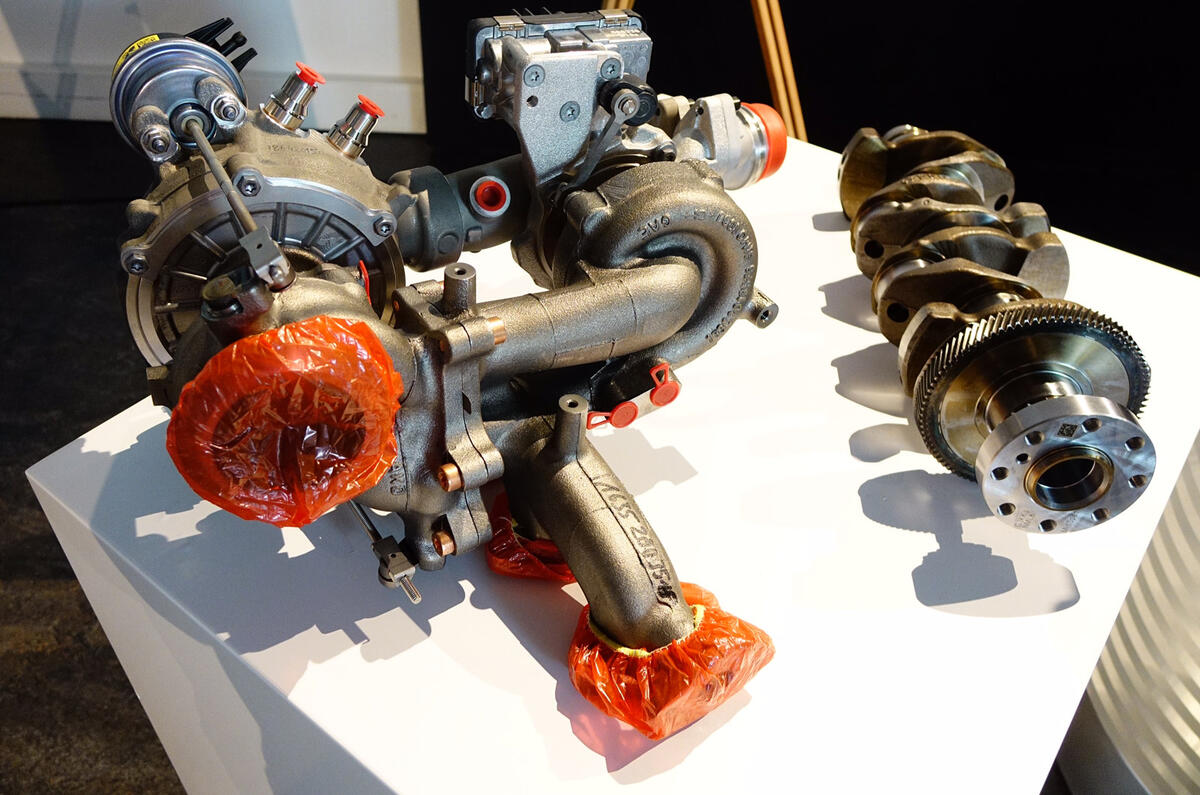

Both diesel and petrol variants will be equipped with turbochargers, with all engines sharing common components and calibrations - thus allowing JLR to react more quickly to changes in demand. All engines will also get direct injection, variable valve timing and stop-start technology.

The first engine from the new family to go into production will be a 2.0-litre turbocharged diesel - dubbed AJ200D. The company says that friction in the unit has been reduced by 17 per cent compared to the current 2.2-litre diesel engine.

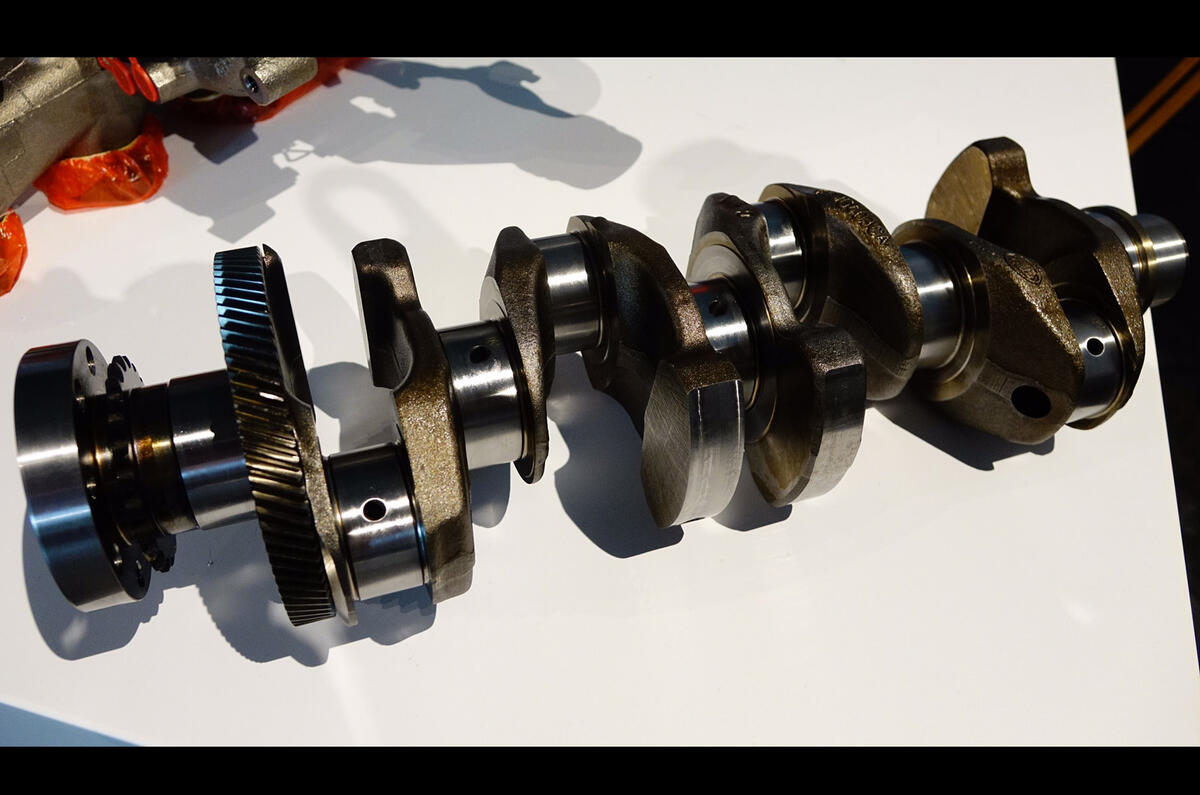

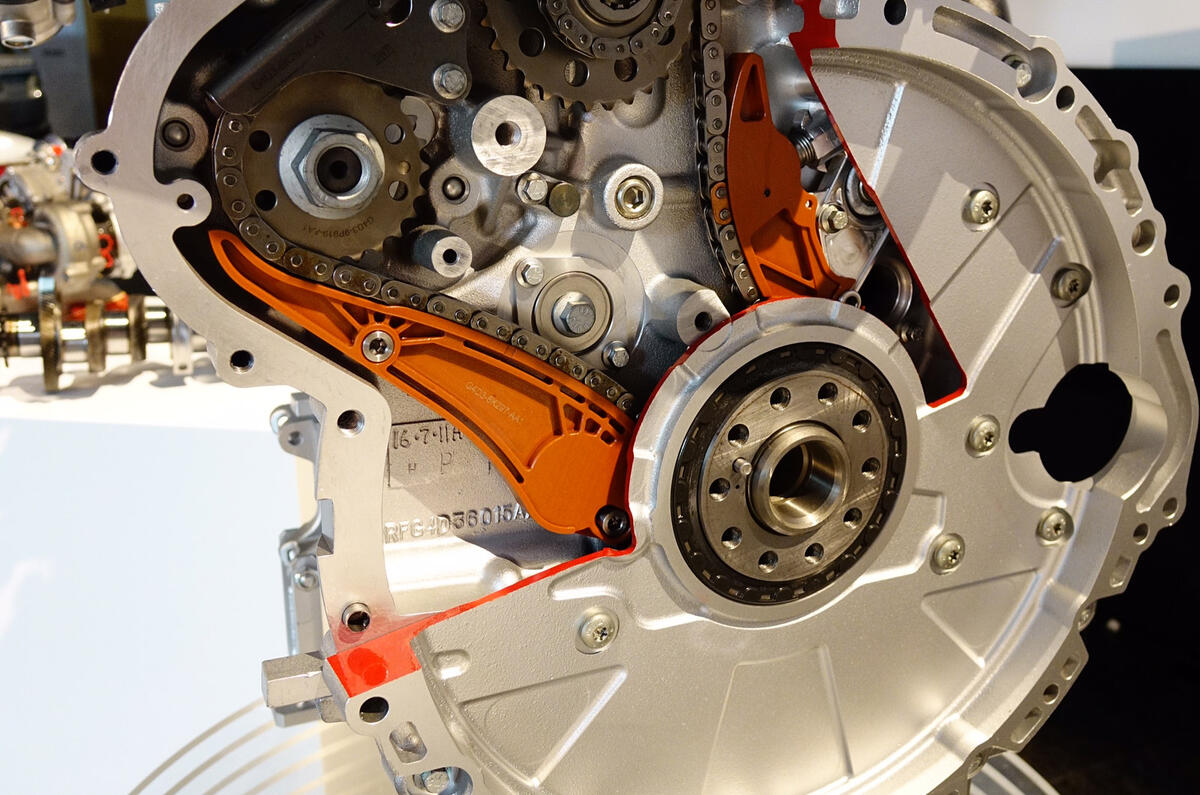

Key to reducing that friction is a number of technologies, including computer-controlled oil and water pumps, cam followers running on roller bearings, a roller-bearing equipped balancer shaft and electronically controlled piston-cooling jets.

The firm's director of powertrain engineering Ron Lee said: "Being configurable and flexible are the two key strands of Ingenium’s DNA because we have future-proofed our new engines from the outset. Ingenium will be able to accept new advances in fuel, turbocharging, emissions, performance and electrification technologies when they are ready and accessible to be deployed.

“We were able to design Ingenium in this way because we had the rare opportunity to start the project with a clean sheet of paper. We weren’t locked into any of the usual restrictions that force engineering compromises because we had no existing production machinery that would dictate design parameters, no carryover engine architectures to utilise and no existing factory to modify."

JLR says that the new range has been tested on more than two million miles of real roads prior to reaching production. The engines will be built at the company's new Engine Manufacturing Centre near Wolverhampton - which forms part of a £500 million investment by JLR.

Join the debate

Add your comment

How the Story has Changed

Seems innovation was at a standstill until governments around the world "rocked the boat".

Although cam chains are pretty reliable this one will require removal of the engine to replace, pity the second and third owners.

I agree with WILL86 above and have already gone electric.

All sounds good, and I hope

3.0 I6?

Autocar wrote:The company

I think I can see where ~10% of that drop in friction came from without even being an engine designer!