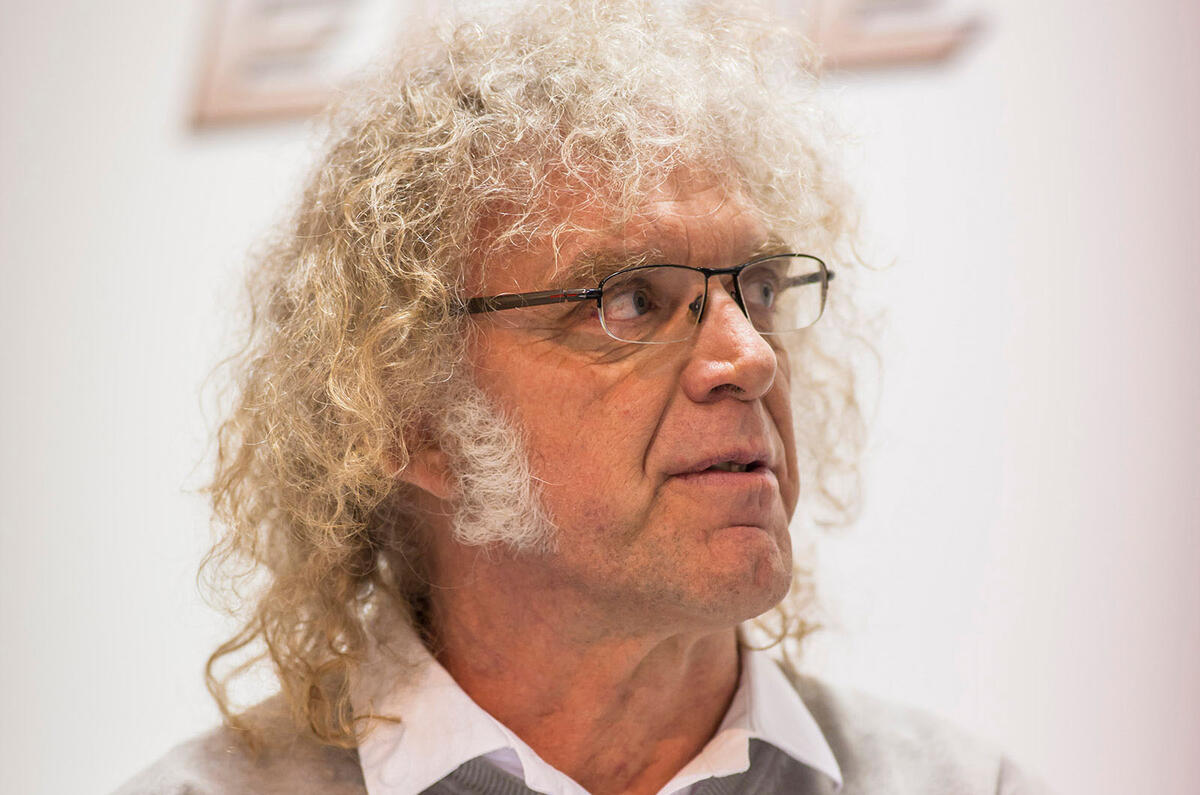

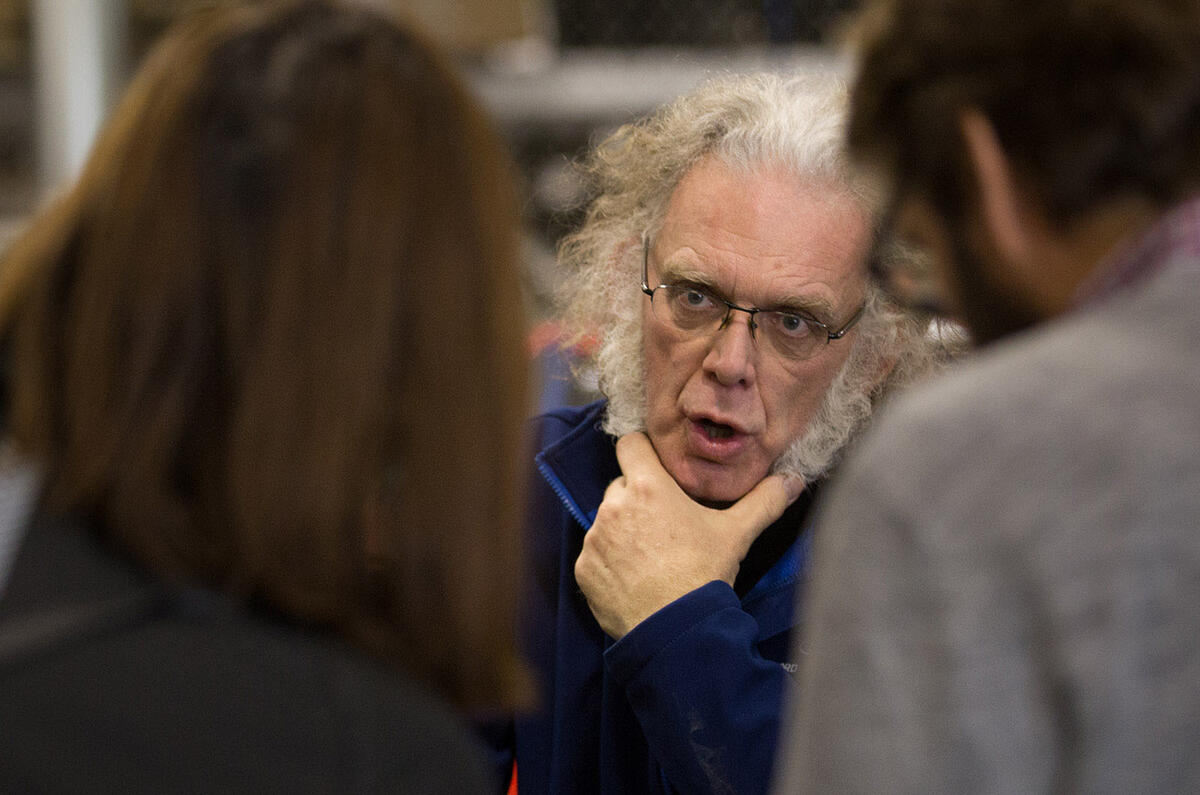

When people first meet Larry Holt, some get a bit hung up on his haircut. Or lack of it.

Safe to say Holt is the world’s only 57-year-old vice-president of a billion-dollar car group whose straggling shoulder-length grey locks and accompanying casual apparel indicate both an abiding disdain for barbers’ shops and for formality in all its guises.

This does not, however, stop him being one of the world’s foremost experts in complex car engineering and manufacture, with special expertise at bringing intricate supercar projects to life.

Still, on first contact, you can’t help wondering how Holt’s unique appearance plays with denizens of sartorial correctness such as the top people at Ford, GM, AMG or Aston Martin, with whom he does high-level deals.

These, after all, are the people who believe great grooming gets you up the greasy pole. Yet when you talk to them about Holt’s engineering division of Multimatic – the vehicle for Holt’s success and the business he has expanded from an original Toronto-based staff of five to 900 in a dozen transatlantic locations – you discover that they don’t just like this guy, they love him. “Larry’s amazing,” says one. “When he accepts your job, you know what comes back will be better than what was promised.”

In the past couple of years, Holt has reached a new level of personal prominence via Multimatic’s involvement in super-sophisticated, low-volume supercar projects such as Aston Martin’s One-77 and Vulcan, and the latest Ford GT – both the Le Mans-winning racer and the 1000 road-going models now being built. Work on Mercedes-AMG’s Project One is proceeding, too, somewhere away from prying eyes.

Add your comment