Toyota is the largest vehicle maker in the world, having last year built 8,885,533 cars, trucks and buses across five continents.

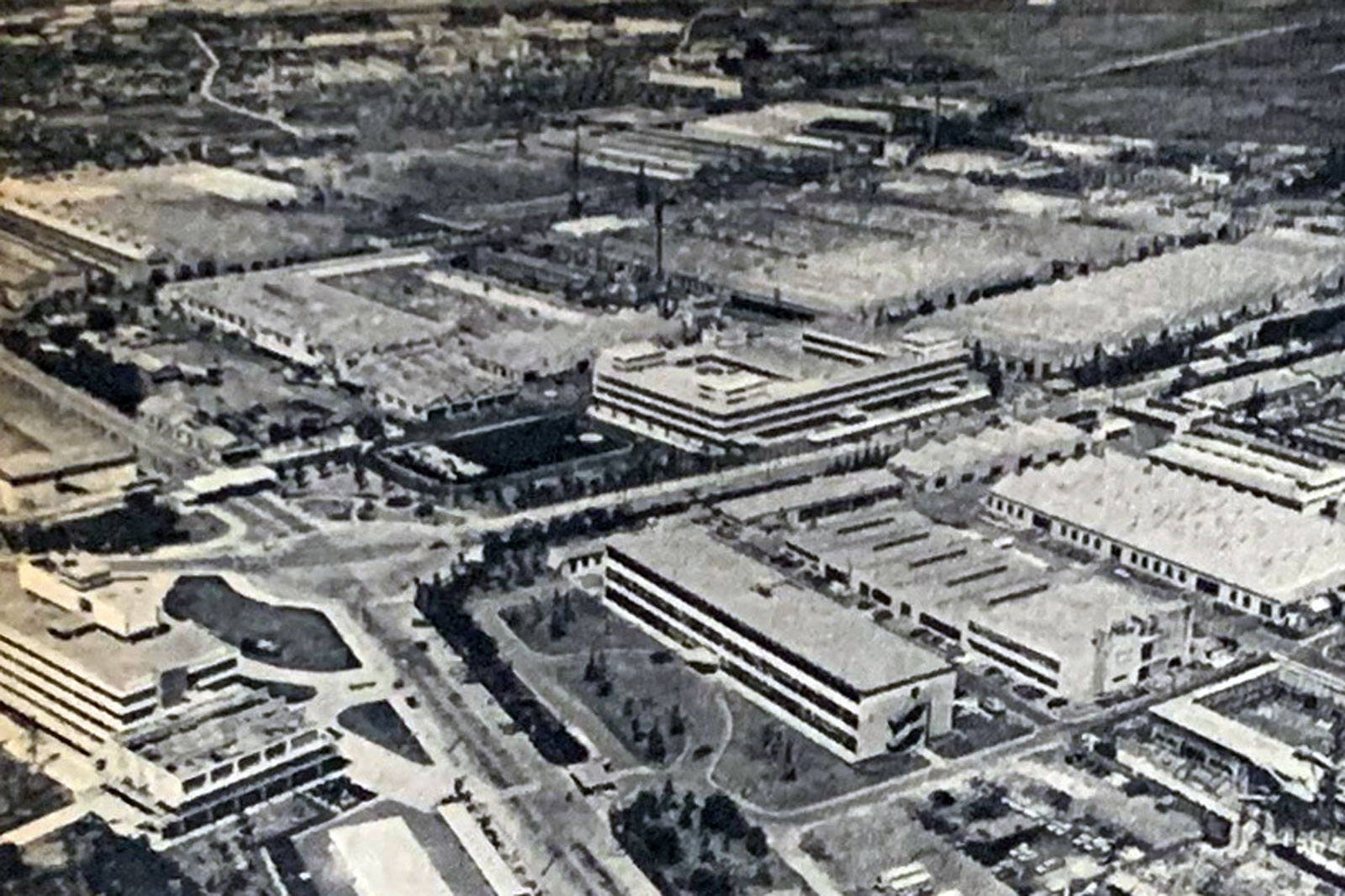

Its rise from a maker of automatic weaving looms to its position as a leading manufacturer of such complex products was rapid. Back in 1964, just 28 years after building its first car and only 20 years after a war-imposed hiatus ended, it was already up to an annual figure of 425,764 (181,738 of those being cars). That put it well ahead of any of its various compatriots and responsible for nearly 34% of Japan's total vehicular output.

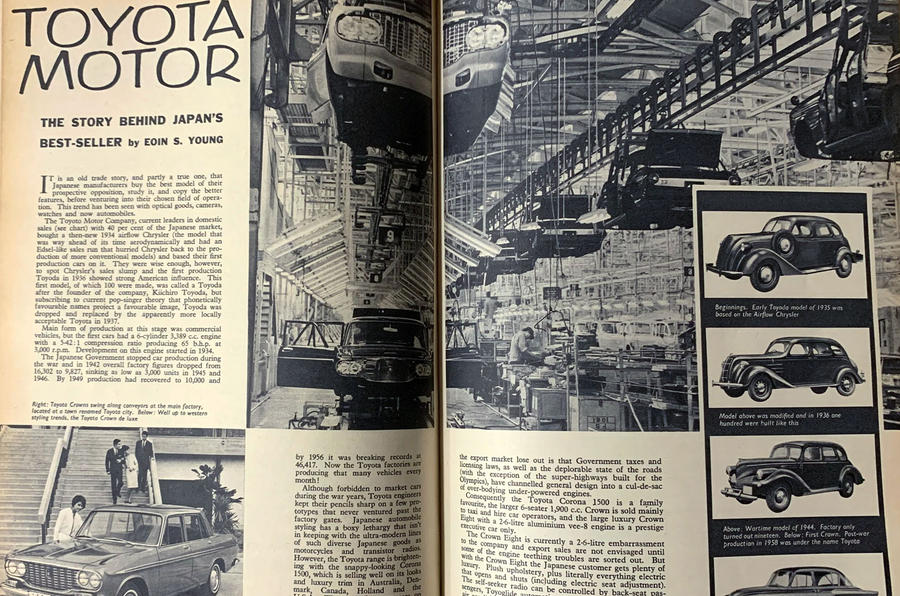

It was in July of the next year, 1965, that Autocar sent reporter Eoin Young to Toyota City to find out about this exciting company. Whether we were aware of it or not, come that October the firm's cars would be on sale here, starting the influx of high-quality products that would ultimately put paid to Britain's decrepit domestic makers.

"It is an old trade story, and partly a true one," introduced Young, "that Japanese manufacturers buy the best model of their prospective opposition, study it, and copy the better features, before venturing into their chosen field of operation. This trend has been seen with optical goods, cameras, watches and now automobiles."

He explained that the formative Toyota AA saloon of 1936 had largely aped the Chrysler Airflow, an American design that was "way ahead of its time aerodynamically but had a [Ford] Edsel-like sales run that hurried Chrysler back to the production of more conventional models". This used an engine, in development since 1934, with six cylinders, a 3.4-litre capacity and a 5.42:1 compression ratio to produce 65bhp at 3000rpm.

This found minor success, shifting 1404 examples, but Imperial Japan soon entered into the war against the Allies, and so the factories were switched to only military truck production.

Join the debate

Add your comment

xxxx...where are you...?

Wish you were here...