Slide of

Slide of

There are manual and automatic gearboxes, right?

Not quite, as we find out with this look at the many different types of transmission used in cars present and past. They are arranged in alphabetical order:

Slide of

Slide of

Brinn two-speed

In the world of oval racing Brinn’s two-speed transmissions are highly regarded. Not only are they very reliable and easy to rebuild, the simple cleverness of the design makes it quick to change gears and much lighter than many rival gearboxes.

The success of the Bring gearbox is due to its reverse gear not meshing with any others when the transmission is in its direct drive second gear. This reduces mechanical drag inside the gearbox, while the lower first gear is in constant mesh that means only a dog ring is used to make the shift. The result is you don’t have to wait for the gears to mesh together, making for quicker shifts and a more compact gearbox.

Slide of

Slide of

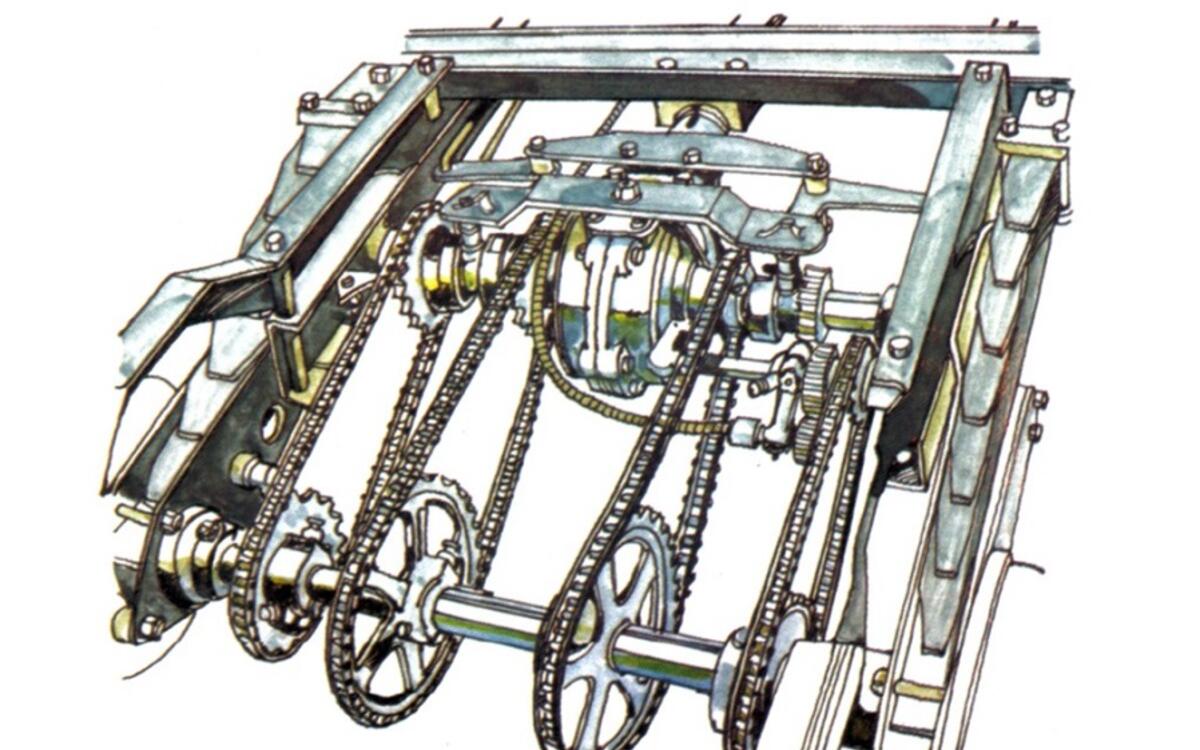

Chain drive

Not a gearbox as such, chain drive was a hangover from the early days of motoring before smoother, safer differentials became the norm. The greatest exponent of the chain drive system was British sports car firm Frazer Nash and its demon quick cars that performed well in hillclimbs, sprints and racing.

The chain drive system takes power from the engine through a clutch to a bevel box that turns the drive through 90-degrees. Power is then transmitted to the solid back axle by chains, with different chains for each gear and dogs used to prevent two ratios engaging at the same time. It makes for quick gear changes and the solid back axle gives good traction on low-grip surfaces, but it also makes the cars a handful in corners.

Slide of

Slide of

CVT

The continuously variable transmission (CVT) is a very simple idea that uses two cones connected by a drive belt. One cone is attached to the engine and the other to the driven wheels. Using the differing ratios offered by the cones, this gearbox provides much of the same driving experience of a normal automatic transmission.

Where a CVT differs from an auto is when the driver presses on the throttle. The engine revs rise quickly and the car’s speed then builds as the cones vary their interaction while keeping the connecting belt taut. A CVT gearbox is smaller than a standard auto, so helps with packaging, but the way it works is often regarded as a hindrance to refinement.

Slide of

Slide of

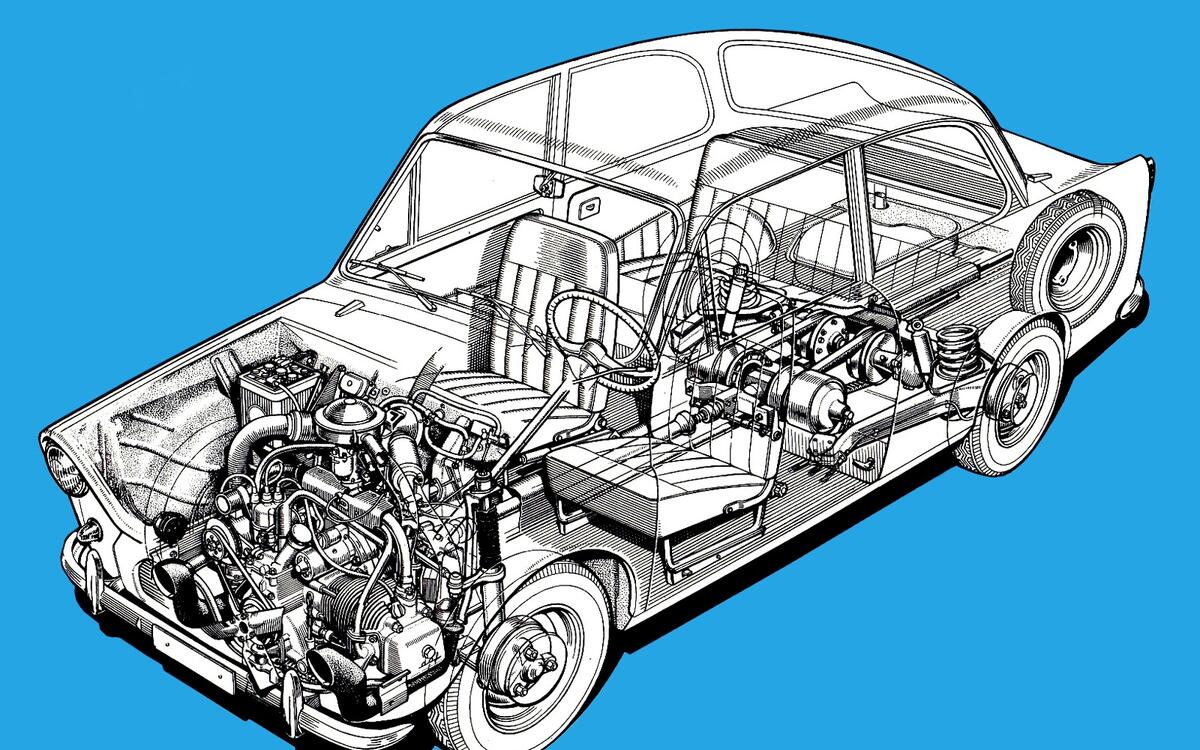

DAF Variomatic

Dutch firm DAF was the first use a continuously variable transmission in its 600. Designed by Hub Van Doorne, this system works using two conical drums with a belt between them. Depending on the engine’s speed and how hard the driver presses on the throttle, the cones slide closer together to increase speed or further apart to slow down.

In the DAF 600, power was delivered to each rear wheel by a separate rubber belt. With no dedicated reverse gear, DAF got round this by simply reversing the direction of drive in the gearbox, so the 600 could, in theory, drive as quickly backwards as forwards.

Slide of

Slide of

Dog gearbox

The dog ’box gets its name from the shape of the gears on the cogs, which are larger than a standard transmission’s and protrude like canine teeth. They also bite together in a much harder fashion than a normal road car’s gearbox with synchromesh as a dog ’box doesn’t have this system to smooth changes. Without this, a dog gearbox is only really suited to race cars where quicker, more aggressive changes are desirable.

With no synchromesh, the driver needs to rev match with a dog gearbox, though the larger, stronger cogs give some leeway if the engine and road speeds are not perfectly in balance. The downside is a dog gearbox requires the driver to be very deliberate with every gearchange, which is fine on the race track but tiring on the road.

Slide of

Slide of

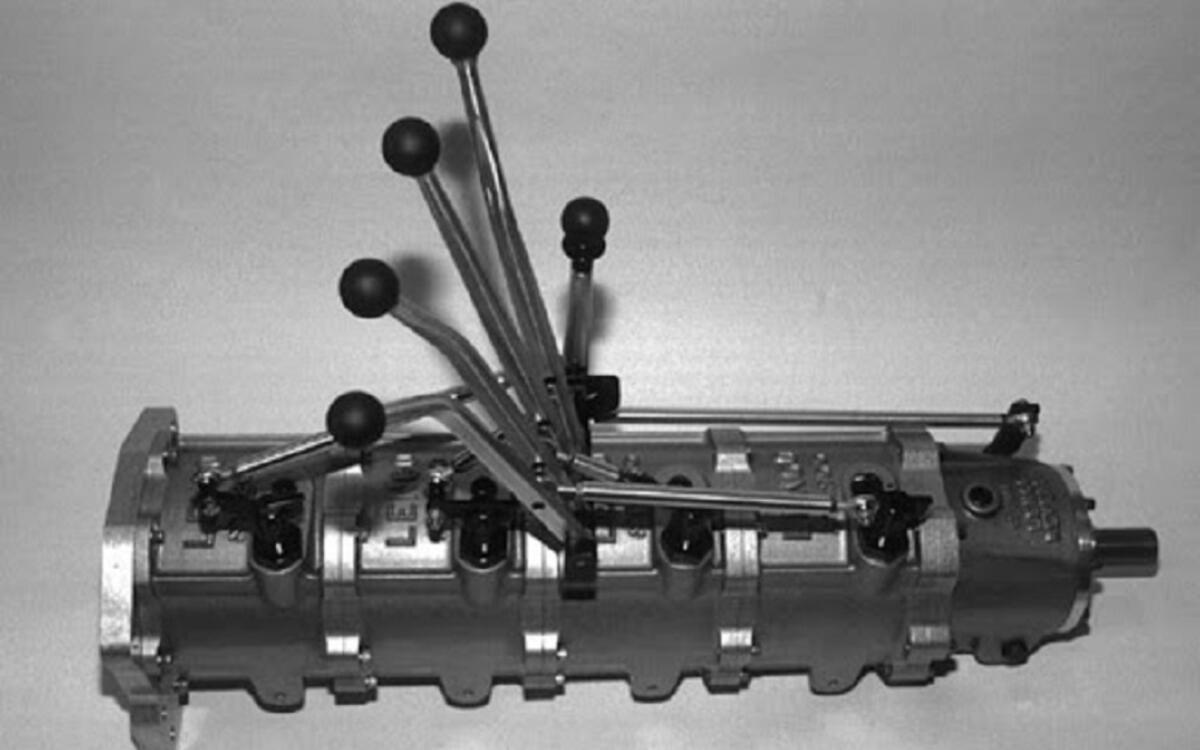

Drag race car

With the most powerful drag race car engines producing as much as 11,000bhp, you need a special gearbox to cope with that power. This is where specialists like Jerico, Lenco and Richmond Performance come into their own. Most use a planetary design with a central sun gear with a planet gear circling it to give a lower underdrive ratio and direct 1:1 final drive. For more gears, you simply add another case to the transmission, which is why many drag cars have multiple levers that the driver pulls during a run to engage the next gear.

These gearboxes are not only extremely strong, they offer incredibly quick shifts without the need for the driver to lift off the throttle. That’s the key to a quick run on the drag strip as there’s no delay in power delivery.

Slide of

Slide of

Direct shift gearbox

A direct shift gearbox (DSG) uses two clutches, so it’s also known as a DCT (dual clutch transmission). The purpose of two clutches in this automatic ’box is it can select the next gear in advance and make a swifter change when it comes. This is achieved by sensors monitoring the throttle, road speed and engine speed.

A DSG gearbox effectively works as two independent gearboxes, each with its own clutch, housed in a single casing. There’s no torque convertor as with a traditional automatic gearbox, which means there are fewer transmission losses and thus better fuel economy. However, DSG gearboxes can be wrongfooted if the driver suddenly changes behaviour, leaving the system struggling to find the right gear.

Slide of

Slide of

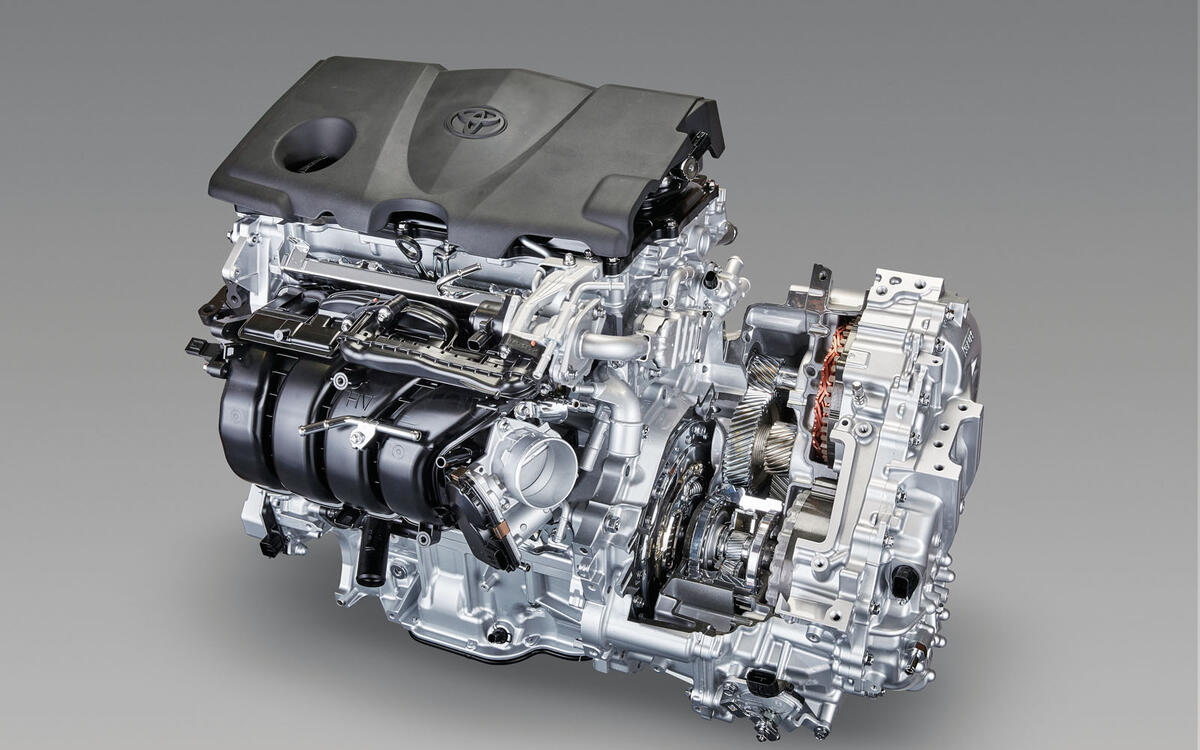

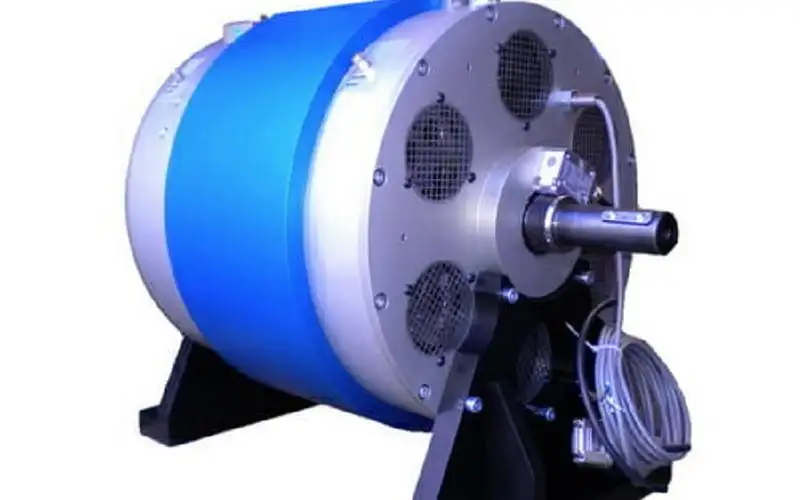

Electric variable transmission

Unlike a CVT (continuously variable transmission) that uses belts to transfer drive, an EVT (electric variable transmission) works using two concentric rotors. The inner rotor takes its drive from the engine or electric motor, while an outer rotor is connected to the driveshafts to the wheels. This means there are only two moving parts in this gearbox and the only maintenance items are the slip rings.

EVTs are still being developed, but they are gaining popularity as they are compact, easily used with hybrid power systems, and offer better efficiency than CVT gearboxes. They can also be used for regenerative braking without the need for any other equipment, further saving weight and complexity.

Slide of

Slide of

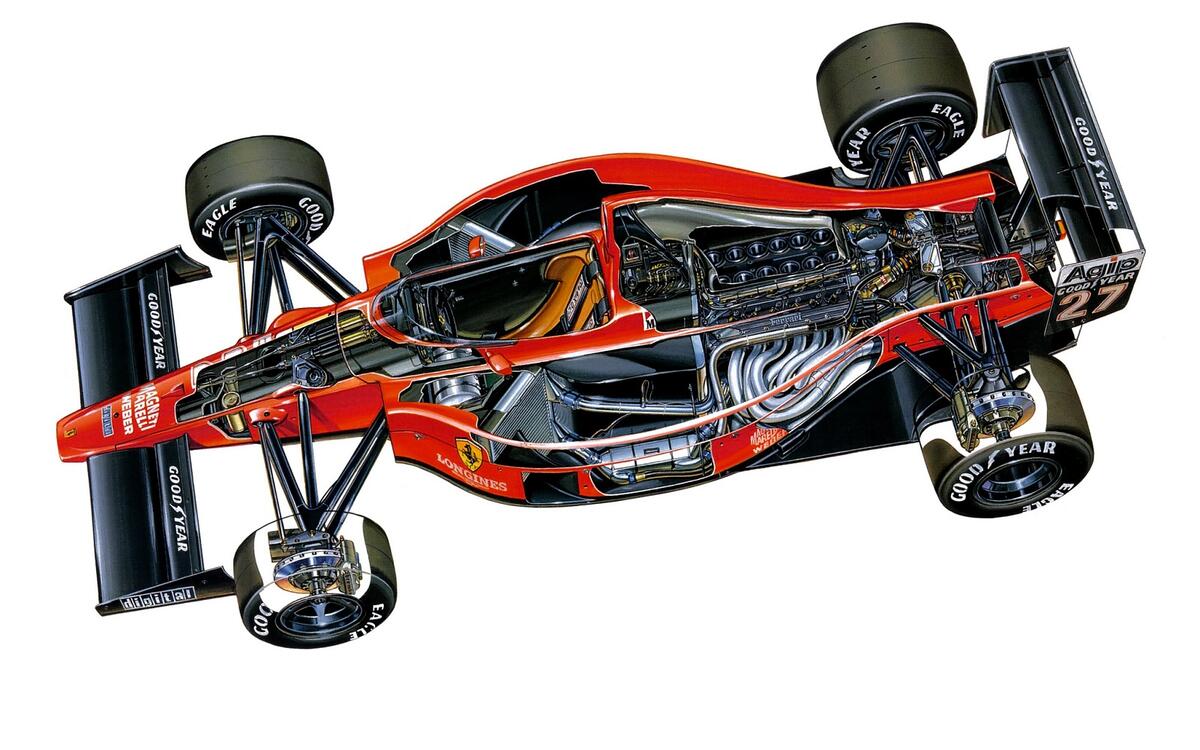

F1 sequential gearbox

Formula 1 is a hotbed of innovation and it was here that automated sequential manual gearboxes were rapidly developed before making a debut in 1989 in a Ferrari. The main benefits of this type of transmission are much quicker changes, taking only 30-milliseconds compared to the best a human can manage of 200-milliseconds, and it lets the driver keep hands on the steering wheel. An electronically controlled gearbox also eliminated the risk of the driver over-revving the engine on a down change with expensive consequences.

Electro-hydraulic actuators shift the gears when the driver pulls on the steering wheel-mounted paddle. The gears are arranged sequentially like a motorcycle’s, so the driver can only go up or down in sequence rather than block-changing multiple ratios at a time. The latest Formula 1 transmissions have eight forward gears and a reverse.

Slide of

Slide of

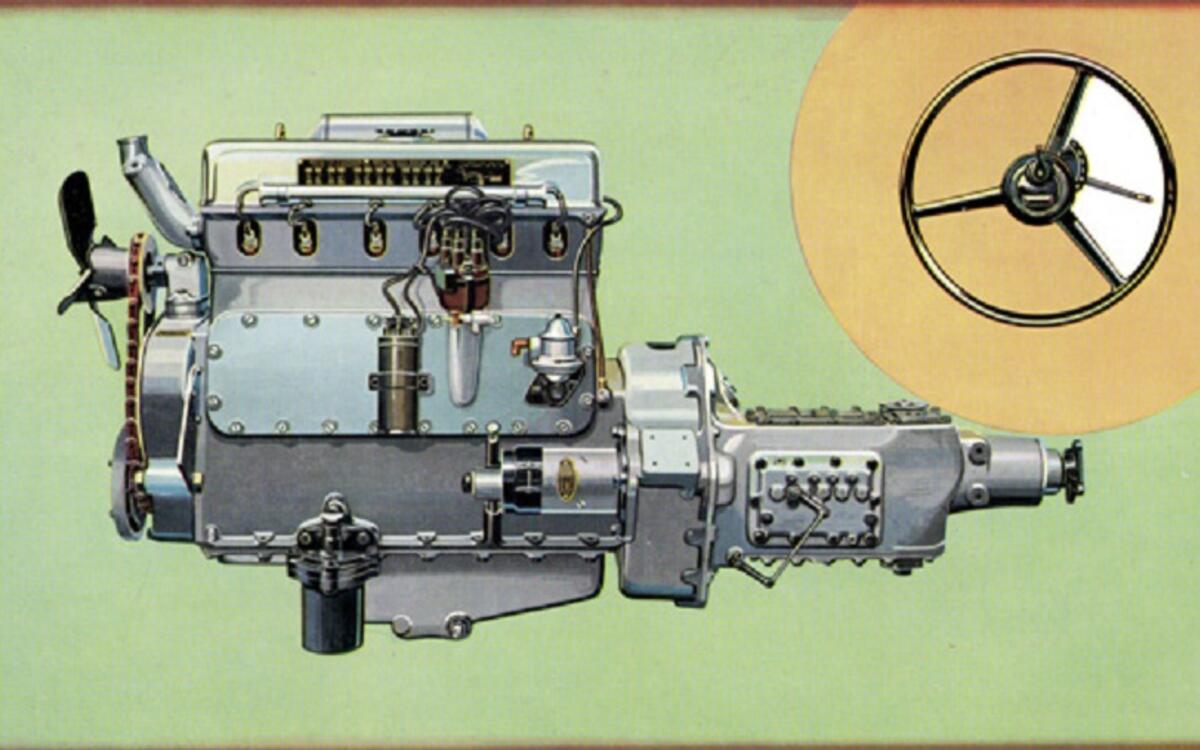

Non-synchromesh manual

Also known as a ‘crash’ gearbox for the noise it can make with a mis-timed shift, the non-synchromesh transmission is now only usually found in some trucks. It was once the common gearbox in cars in the pre-war period. Selecting first at a standstill was easy, but the driver then needed to match engine and gearbox speed, which was dictated by road speed, to achieve a smooth change.

To make crunch-free changes, drivers would double-declutch, depressing the clutch pedal twice between shifts rather than once and revving the engine to give the motor and transmission a chance to engage smoothly. Simple to build and rugged, non-synchro gearboxes were largely redundant by the 1950s.

Slide of

Slide of

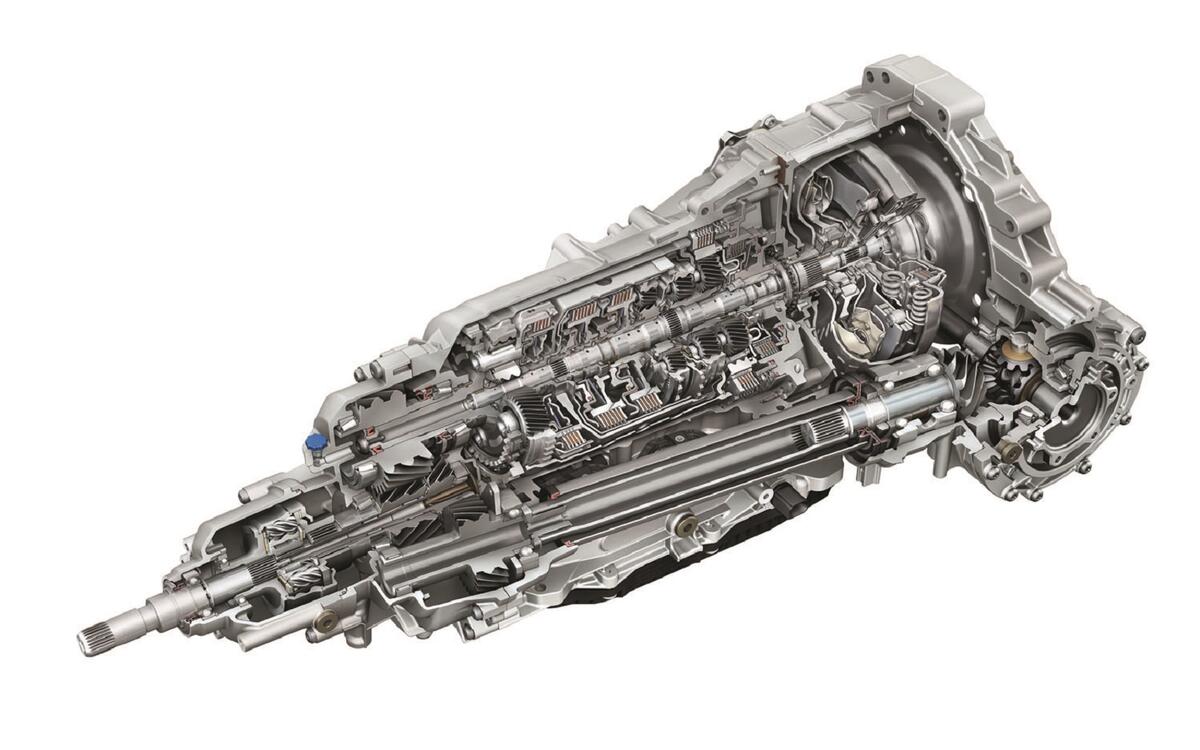

PDK

The dual-clutch transmission was first thought of in the 1930s for use in a Citroën, but it was Porsche that ran with the idea in the 1980s. With the catchy name of Porsche Doppelkupplungsgetriebe, the German firm alighted on the abbreviation PDK for its first use in a 1982 956 race car. Using two clutches instead of one, it allowed for fast gear changes, which Audi used to its advantage in the 1985 Group B Quattro rally car.

The first production road car with a PDK-style gearbox was the six-speed Volkswagen Golf R32, which was followed by a seven-speed version. However, it took Porsche until 2008 to introduce the PDK (in the Porsche 911 997.2), which has two clutches with the odd-numbered gears on one and even-numbered gears on the other. The gears are already engaged when changing, so there’s no delay in acceleration and smoother shifts. It uses a 'wet' clutch approach (one immersed in lubricant), a key differential from the 'dry' approach of DSG.

Slide of

Slide of

Pre-selector

The pre-selector gearbox was a solution to early non-synchromesh ‘crash’ transmissions. These gearboxes did away with the need for the driver to double de-clutch and match engine revs to transmission speed, making for simpler, quieter progress. However, pre-selector gearboxes were subsequently outmoded as automatic transmissions took over in the post-war period.

A pre-selector gearbox works by letting the driver choose the next gear without the car changing ratio. The gear is then engaged by a gear change pedal rather than a clutch. The most common type of pre-selector gearbox was designed by Walter Wilson (1874-1957) and used an epicyclic design; an early associate of Charles Rolls (of Rolls-Royce fame) Wilson is credited as the co-inventor of the tank.

Slide of

Slide of

Saxomat

Saxomat developed the first widely used ‘clutchless’ manual transmission. It did away with the clutch pedal but not the clutch itself. Instead of the driver depressing the clutch pedal, Saxomat’s system used an electric switch to disengage the clutch every time the driver selected another gear with the lever. When pulling away from a standstill, centrifugal force caused the clutch to engage drive.

This system was used by BMW, Fiat, Ford, Lancia and Volkswagen, and a similar version was used by Porsche for its Sportomatic gearbox in the 911.

Slide of

Slide of

SMG

BMW’s Sequential Manual Gearbox (SMG) was always a contentious development, with some considering it too jerky in use and others viewing it as race technology for road cars. It arrived with the E36 M3 in 1996 and was a six-speed manual but with shifts worked by an electro-hydraulic pump that mimics the actions of the driver’s hand and foot.

SMG gained a poor reputation early on as it does not behave like an automatic. The driver has to allow for the delay as the gearbox changes gears and this can take some getting used to in order to avoid jerkiness. There were also problems with the hydraulic pump motors, relays and solenoids that led to reliability concerns.

Slide of

Slide of

Sportomatic

Despite what the name suggests, Porsche’s Sportomatic transmission is not an auto ’box. It’s an automated manual system that works when the driver selects a gear with the lever, but there’s no clutch pedal. A micro-switch in the gear lever detected movement and signalled a solenoid to open a pneumatic valve. This disengaged the clutch and allowed the driver to move the lever into the next gear in the traditional H-pattern gait.

The difference with the Sportomatic over other similar systems is it also had a torque convertor like an automatic gearbox. This prevented the engine from stalling when the car came to a halt even if the car was still in gear. The Sportomatic started life in 1967 with four gears but was later changed to just three.

Slide of

Slide of

Synchromesh manual

To overcome the need for double de-clutching when changing gear and the risk of crunching if this was mis-timed, synchromesh was developed. The first to use this technology in a road car was Cadillac, but it was Porsche that came up with the split ring system in 1947 that went on to be used in most manual gearboxes. Porsche was the first to use synchromesh on all forward gears in its 1952 356.

There are three main parts to a synchromesh gear: the gear cog, baulk ring and synchromesh unit. As the driver changes gear, a selector fork presses on the baulk ring and this engages with the chosen gear. As they spin at the same speed, the synchromesh unit slides over the baulk ring at the same rotating speed and lets the outer teeth mesh with the main gear to complete a smooth change. Every gear in the ’box has its own synchromesh, which means this type of transmission is bulkier than non-synchro ’boxes but it’s much easier to use.

Slide of

Slide of

Tiptronic

A Tiptronic gearbox is an auto transmission that lets the driver choose a gear by moving the lever or paddles. However, this is not manual selection as the car will not let the driver override what gear it’s in if it could damage the gearbox. The main reasons for a Tiptronic shift are it gives a sportier feel and lets the driver control speed on downhill stretches by using some engine braking.

Porsche coined the name Tiptronic when it offered this type of auto ’box in its 1990 911. Many other car makers now use similar systems with their own brand name attached.

Slide of

Slide of

Torque convertor auto

The most common type of automatic gearbox uses a torque convertor to transfer the engine’s rotational force to the wheels. A torque convertor is a fluid coupling that lets the car pull away and stop without stalling the engine, though there is some loss of efficiency as it takes up drive due to the curved shape of the turbine blades inside the convertor.

The first widely used automatic gearbox was offered by General Motors in 1939 with its Hydra-Matic transmission, in 1940 model year Oldsmobiles. Then, in 1948, the first torque convertor auto was used in the Buick Dynaflow. The number of gears used in automatic has grown from two in early transmissions to as many as 10 in cars like the Lexus LC and Ford Ranger to meet emissions regulations.

There are rather more gearbox types out there than you might think? We take a look at them all

Advertisement