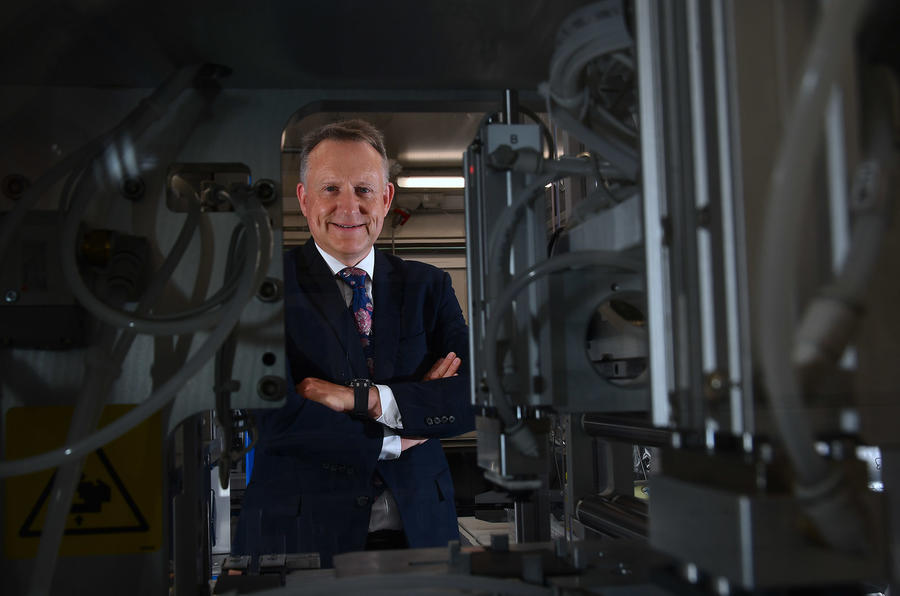

Graham Hoare, newly appointed chairman of Britishvolt, the Northumberland-based start-up that will open the first phase of a 30GWh battery manufacturing business in 2023, recently made a major career change – the kind of move he admits would not have been possible in any other era of motoring history.

For the first 20 years of an illustrious engineering career, Hoare spent most of his time making and improving internal combustion engines. Working first at BMW, then Land Rover and Ford, he led and inspired the creation of some of the automotive world’s most admired powerplants, most recently Ford’s Ecoboost units, which have won consistent plaudits for their sophistication and affordability. So good was his performance that he was eventually given sign-off authority for Ford’s global product line-up, and then appointed chairman of Ford of Britain at the remarkably young age of 52 – a position from which incumbents usually retire gracefully. But not Hoare. For at least half his career the eventual automotive transition to battery power has been visible on the horizon, Hoare said, but the event that catapulted him into his new electrification role wasn’t automotive at all.

To receive the latest industry news, please click here to sign up to the Autocar Business newsletter

He explained: “My awareness of this new world accelerated during the early days of the pandemic when, working with government and partners, we at Ford built 12,000 desperately needed ventilators in 105 days, employing 2500 people in three factories around the country. It was exhilarating. We were scared to death half the time, but I loved the urgency and the need for quick decisions. It made me more aware than ever that the UK is the best place in the world for collaboration.”

At the same time, Hoare said, demand for electric cars began accelerating – a clear sign that the electric transition was coming “faster than we thought”. So when the chance came to head the UK’s first big-scale investor in battery technologies, a company with a breakneck timetable attached from day one, he decided to grab it with both hands.

Join the debate

Add your comment

Symanski - yet another negative post. You spend your whole time on here doing people or ideas down. This is seriously ambitious project and company, it will be needed in the UK as the automotive giants don't have the capital to build these factories alone as they move to BEVs. To get off the ground a more than signifcant amount of due dilligence will be done by investors, so perhaps better to welcome the fact that this entrepreneurial company is looking got create such a huge investment and employment opportunity in the UK despite as you'll know doubt bring up that Brexit is the end of the world.

You spend most of your time obsessing about BMW engines, the Aston designer, and Brexit. Hopefully there's something a bit more positive in your life than moaning on this site.

Give them a chance - at least they are giving it a go.

Still a company with absolutely nothing to show.

All management, no workforce. No factory, no intellectual property.

It's like a ferry company with no ferries that uses pizza shop contacts... Remember that?