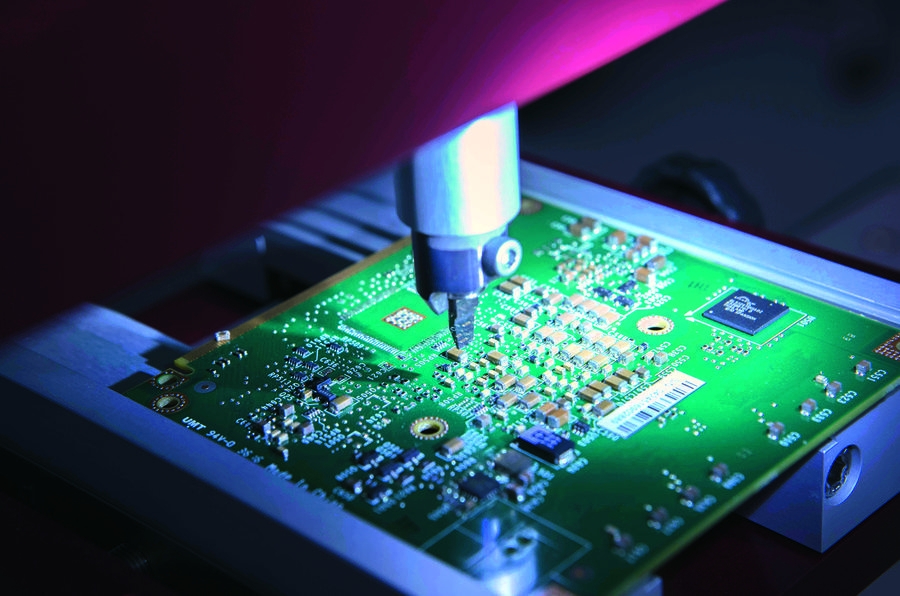

German engineering and technology company Bosch has opened a new semiconductor factory with the goal of supplying the automotive industry, among other business areas.

Computer-chip production for Bosch power tools is expected to begin in July this year, six months earlier than initially planned, before production for automotive customers begins in September.

The factory in Dresden, Germany, has cost the company around £860 million (€1 billion) to build and is expected to provide 700 jobs.

The automotive industry has been heavily impacted by a global shortage of semiconductors during the pandemic, resulting in several manufacturers seeking to overhaul their components supply chains.

The shortage, initially caused by an unprecedented rise in demand, has been exacerbated by a chip-plant fire in Japan and blackouts in the chip-making hotspot of Texas, US.

Bosch has implemented significant artifical-intelligence technology in the Saxony facility, which the company says will “save automotive customers the need for the time-consuming trials that would otherwise be necessary before production release”.

“Chips for vehicles are the ultimate discipline in semiconductor technology," said Bosch board member Harald Kroeger. "This is because in cars, these small building blocks have to be especially robust."

Bosch says the development of automotive semiconductors is more complicated than in other areas, requiring “specialist expertise” that it claims to have amassed over the past few decades.

“In 2016, every new vehicle worldwide had an average of more than nine Bosch chips on board, in devices such as the airbag control unit, the braking system and the park assist system," the firm said. "In 2019, this figure was already more than 17."

READ MORE

Inside the industry: Why the semiconductor shortage hits hard

Semiconductor crisis: Nissan's record annual loss, Ford predicts 50% capacity in Q2

Analysis: Chips are down for car makers as shortage continues

Join the debate

Add your comment

Can't see this being a small feature sized plant. That figure on the cost is a fraction of what such a plant would need to be. But for microcontrollers that would be part of Bosch's control modules probably good enough.

The infotainment systems will probably require devices which are smaller features to be more power efficient.

The real sadness is that Scotland had a plant, near Dunfermline, which never produced a single chip yet was set up for state of the art production. Hyundai spent billions building it only to never use it, Motorola bought it only to never use it either. And then it sat empty, just on the cusp of being kitted out for production.

Politicians celebrated its eventual demolision, yet that was thousands of jobs that never came to the area. A plant which now would be in high demand. Even if it was still there, mothballed, it would be given a chance of life now as it would be quicker to get in to production than one which needed built fresh.

A sad missed opportunity.