There has been an awful lot of love out there for manual gearboxes of late, maybe because we’ve reached a point where some kind of automatic is the norm. All of a sudden, the dual-clutch transmission (DCT), which promised so much driving satisfaction, has become demonised because keen drivers still lust after a stick-shift for the most engaging driving experience.

Manufacturers haven’t given up, though (they can’t, because autos are easier on fuel consumption than human drivers), and one of the latest to arrive is Hyundai’s eight-speed ‘wet’ N DCT. This semi-auto ’box first appeared on the Veloster N in overseas markets, then the i30 N, and now it’s the exclusive fitment on the new Kona N. With that, Hyundai hopes to keep enthusiasts on side.

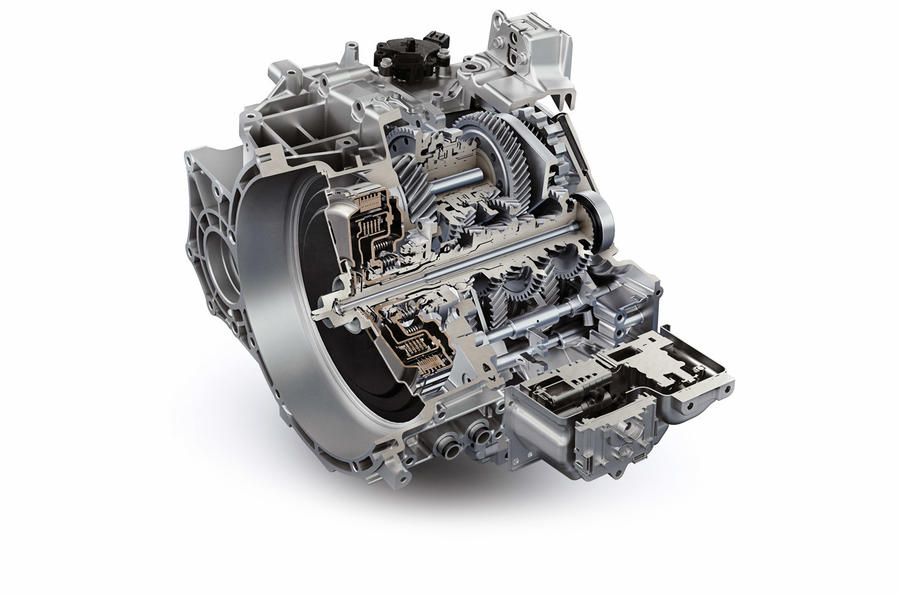

The N DCT is produced by Hyundai’s own parts company, Hyundai Transys. It goes by the codename D8F48W and, specifically intended for high-performance applications, it’s quite the piece of kit. It can handle an input torque of 354lb ft from the engine, has several fancy driving modes (with slightly daft names, such as N Grin Shift) and is no-expense-spared fast.

Like all DCT units, this one is based on a manual transmission, the ultimate expression of an automated manual but with two clutches, doing away with the unpopular torque interruption of its single-clutch forebears. Like most DCTs, the main gear sets are split between two shafts, with one clutch per shaft and forward speeds arranged with odd numbers on one clutch and even on the other. So first, third, fifth and seventh are controlled by one clutch and second, fourth, sixth and eighth by the other.

Smaller DCTs for less meaty applications, like Hyundai’s own seven-speeder, have dry clutches for simplicity, weight and drag reduction; but to manage the wear and heat generation in the higher-torque variety, the clutches are wet, which means they run in oil like a motorcycle clutch pack or torque-vectoring axle.

While smaller dry DCTs may have electric actuators to swap ratios, this one has a hydraulic system and two oil pumps. One is a high-flow pump used to lubricate the gears and cool the clutches and the other develops the pressure for the gear selection system. Both are electric so draw no mechanical power from the engine and maintain pressures independently of the engine and final drive.

The transmission arguably has a higher level of integration with the powertrain as a whole by the way it integrates with the engine. For example, N Power Shift mode engages when the driver is accelerating with more than 90% of the throttle to give a more aggressive upshift, while a brief cylinder cut causes a pop in the exhaust, presumably as a nod to the far more extreme anti-lag system used in rally cars. In N Grin Shift mode, it allows overboost for 20 seconds to give maximum acceleration, but there’s an enforced rest of 40 seconds before the driver can use it again.

Join the debate

Add your comment

There seems to be an assumption that the main reason that those of us who prefer manual gearboxes do so because we want faster shifts? I love cars, and the art of driving so I actually enjoy the whole mechanical interaction of lever and pedal, and me doing it at the right time, its nothing to do with whether an auto does it at the right time or not. I don't understand the intolerance of some people on here on this subject, either. I want the option of a manual 'box, I'm not saying that autos should be banned or not available to those who want them. Its all about choice, something that manufacturers are offering less and less of in todays market.

Manual diehards really die hard. If you still want to control your driving manually, you may do it with a DCT. Lack of foot gymnatic excercise clutch is old fashioned and unnecessary. I stopped warming up my computer with a candle a few decades ago.

Can Hyundai's DCT replace a manual - no of course not. DCTs do not provide the interaction a manual gives just like all other auto's. They like all auto's are now popular with OEM primarily to help them meet RDE emissions by "managing" the limits of how a car is driven

Bosch CVT - electric motors like engines have an efficiency map and are least efficient when running a low RPM. A CVT could well make an EV significantly more efficient saving on battery size (for a given range) and batteries are so expensive it might well be cheaper to fit a CVT than a larger battery. Likely to be very reliable in such an application.