Regenerative braking - using the drive motor as a generator to slow the car – is one of the main advantages of a fully electric or electrified car. The amount of energy that can be recovered is no token gesture, either. Some pure-EVs are capable of recovering a substantial amount of the energy consumed during acceleration each time they slow down.

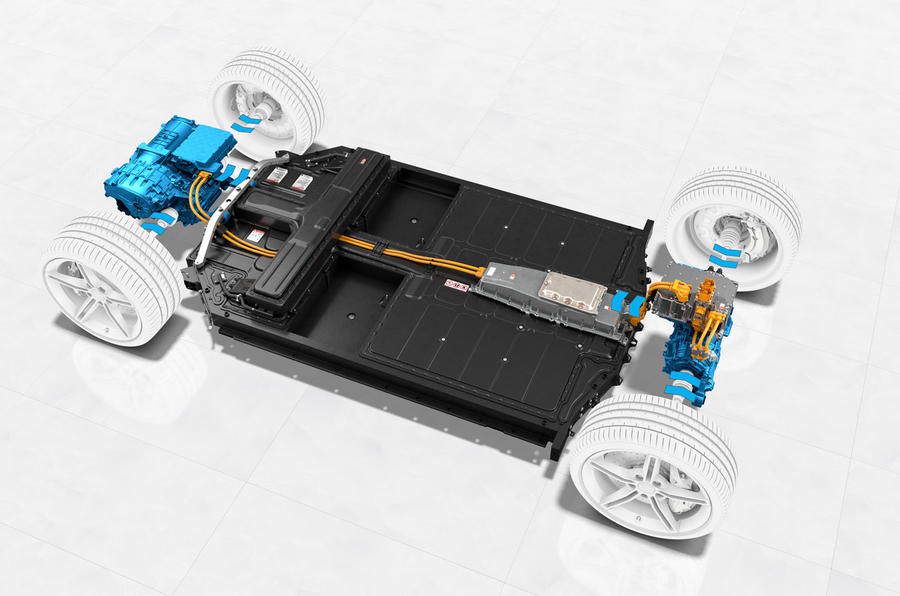

It’s a convenient truth that if electric motors are spun by an external source of power, they generate electricity. This is why engineers prefer to call them ‘electric machines’ rather than ‘motors’. When an EV is in regenerative braking mode, that external source of power is derived from a combination of the car’s weight and the speed at which it’s travelling.

A quick check on the Kia EV Uvo app revealed that our e-Niro’s recent daily average consumption has been 15.92kWh but the amount of power recuperated is a third of that, at 5.96kWh. That’s not to be sniffed at and illustrates the extent to which energy recuperation can affect range.

As experience in designing BEVs and acceptance by users grows, manufacturers are starting to look at how much more efficiency can be eked out of electric powertrains and one way is to increase the amount of energy that can be recovered and stored in the battery for reuse.

Manufacturers are starting to realise that the amount of power their EVs can develop during regenerative braking is becoming a relevant number to quote. It represents something of significant value to users.

For example, Porsche claims the Taycan’s regenerative braking can generate 389bhp of power. That’s equivalent to the power consumed by boiling about 96 domestic kettles. Other EVs do an impressive job at energy recovery, too. For instance, the new Kia EV6 can develop a maximum of 112bhp.

Some EVs, like the Kia e-Niro with its option to manually control regenerative braking ferocity using paddles, can be brought to a full stop without touching the brake pedal. In the Kia’s case, holding the left paddle does just that. So is it simply a matter of time before conventional friction brakes disappear altogether?

DS Automobiles thinks so. No detail has been released yet, but DS is researching the idea and has a working prototype. There are difficulties to overcome, though, the main one being that if the battery is fully charged, there’s nowhere for the electric machine to put the electricity it’s generating.

This implies some additional resource would be needed, such as using the electricity to generate and store the energy as heat, which could be reused, or an additional storage device like reserve battery power or a capacitor, both of which would be expensive. There’s also the question of the instant response conventional brakes can give compared with regenerative braking, especially in an emergency. If the problems can be solved, though, ridding cars of friction brakes would end another source of both wasted energy and particulate generation.

Add your comment