Volvo Cars is planning a 2.5 million-tonne reduction in its annual carbon emissions by reusing and remanufacturing components on a large scale.

The process, which it calls a “circular business principle”, will include recycling key materials such as steel and aluminium, remanufacturing complex components like gearboxes and reconditioning individual parts.

Volvo remanufactured some 40,000 parts last year, saving 3000 tonnes of CO2, and recycled 95% of its production waste (including 176,000 tonnes of steel) to save 640,000 tonnes of CO2.

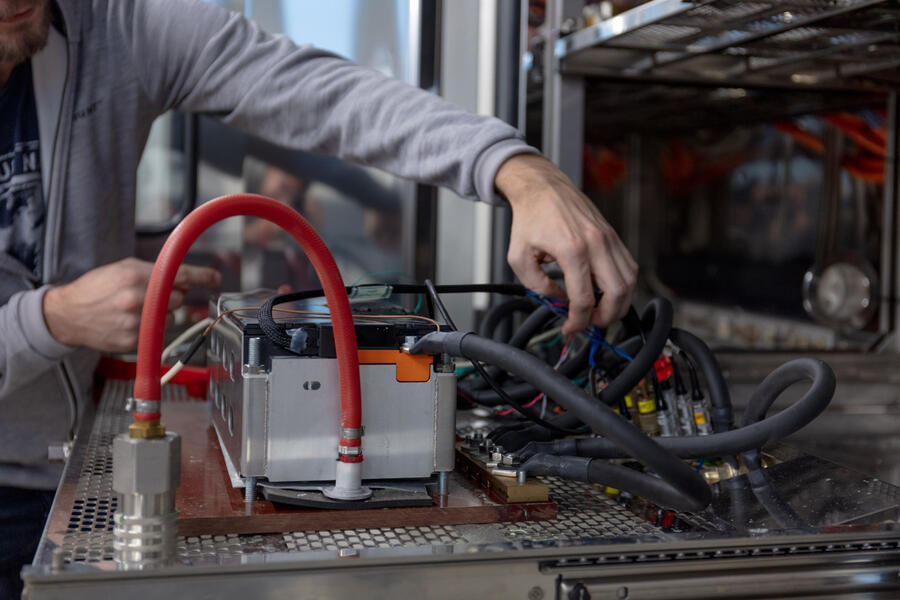

Volvo is also collaborating with battery reuse specialist Battery Loop to investigate the potential for a second life for high-voltage EV and hybrid batteries, all with the intention of becoming a ‘fully circular business’ – using entirely recycled parts – by 2040.

Mechanical components included in the company’s reconditioning programme include brake calipers, electric rear axles, compressors, generators, suspension and chassis parts and EV traction motors, as well as engine blocks and cylinder heads.

Anders Kärrberg, Volvo Cars’ head of strategy and sustainability, said: “There are major sustainability benefits of doing this. If you compare a new part with a remanufactured part, you save about 85% of the CO2. There are major benefits in terms of reducing consumption of the virgin material, too.”

Kärrberg explained that parts such as calipers could be remanufactured three or four times, extending their life to 20 years before being superseded during the evolution of design.

He said: “We’re on the track of doubling the consumption of metals and minerals in the next 40 years, and we’re generating more and more waste. This is simply not sustainable. It’s not just that we’re generating waste materials: we’re also generating a lot of CO2.

Join the debate

Add your comment

Surely the best solution is to make cars last longer and make them simpler. That would be better for the environment. I find all this comment on sustainability from a company focused on selling premium suvs a bit hollow. As for recycling all that steel, that's just done to save money, not to save the environment.

Anyone else not want remanufactured parts on their brand new car? Lack of development/progress, can they fully check the part for wear and cracks, just how many parts will be used - green washing for parts as a message rather than real environmental benefit?

All for reusing parts in used cars, but on new ones not so keen.