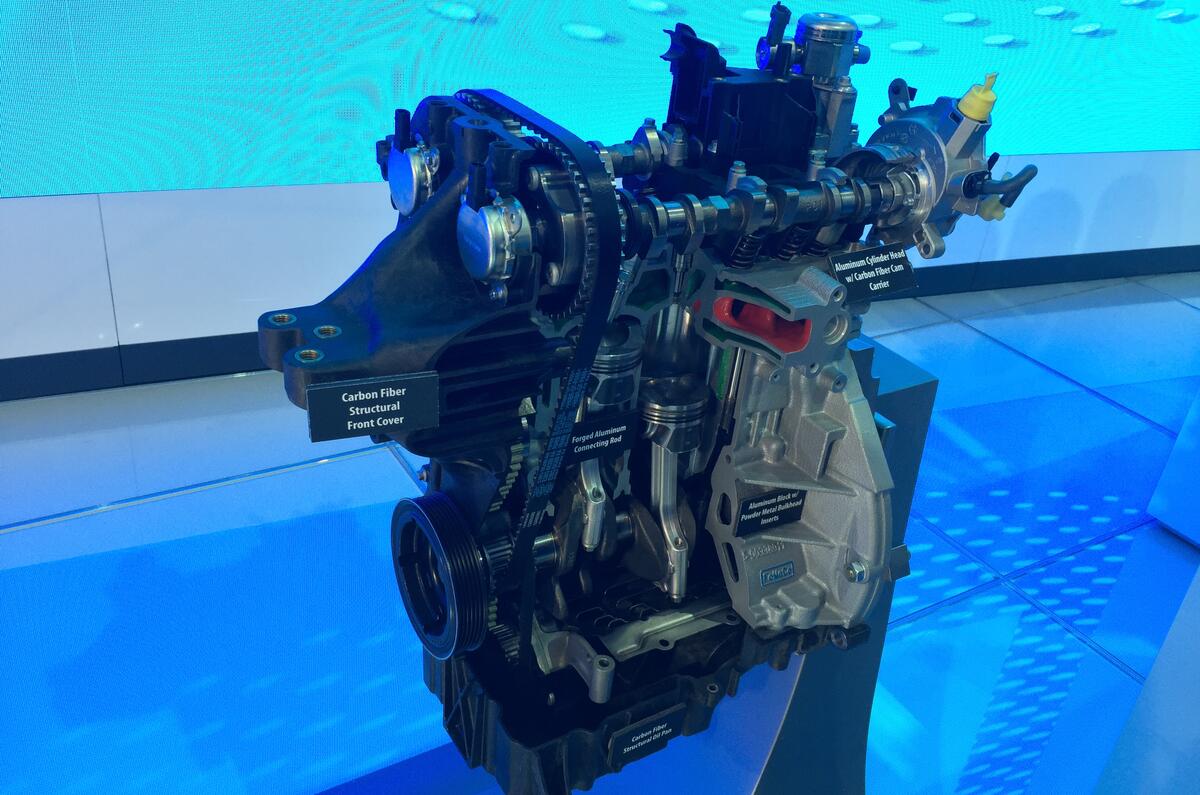

Ford has unveiled a lightweight concept version of its 1.0-litre Ecoboost engine at the Detroit motor show.

In addition to the concept, Ford has also confirmed that it is investigating cylinder deactivation technology for the 1.0-litre engine, allowing it to run on two cylinders.

The lightweight Ecoboost concept has been in development for a year. Five of its major components have been changed, resulting in an overall weight reduction of 15.5% versus the standard Ecoboost engine.

The block, cylinder head, connecting rods, front cover and oil pan are all revised on the conceptin order to help achieve the weight reduction. The block weighs 40% less, at 14kg, thanks to new materials, structure and assembly techniques, the cylinder head is half made from carbonfibre, the connecting rods are made from forged aluminium and carbonfibre is used for the front cover and oil pan, which improves NVH as well as saving weight.

Ford is also investigating cylinder activation technology on the engine, which would shut down the middle cylinder.

Andreas Schamel, director of powertrain research and advanced engineering, said an engine smaller than three cylinders would have too many compromises, but shutting down one cylinder in a three-cylinder engine would improve the economy and fun-to-drive characteristics without any trade off.

Join the debate

Add your comment

Iron

Not just weight

vw