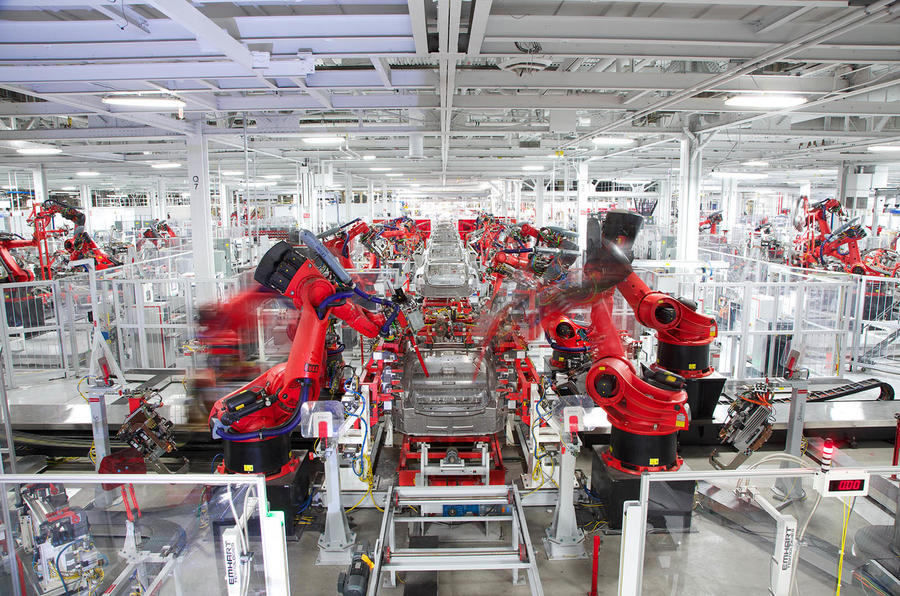

Tesla has upped the pressure on its workforce in order to meet its production targets, particularly so in the dying days of the second quarter, when 5000 cars a week was the company’s aim.

Reuters reports that 12-hour shifts are now being used, while a policy to warn workers a week in advance of weekend shifts - which are now mandatory - has been withdrawn.

Quoting an anonymous source from Tesla’s factory in Fremont, California, US, Reuters reports that the all-hands-on-deck approach taken to pushing the Model 3 to 5000 units per week by the end of the second quarter put the Model S production line 800 cars behind schedule at the paint stage.

“They’ve been throwing Model 3s ahead of the Model S to get painted to try to assure that they make their goal of 5000", a production worker said. "The paint department can’t handle the volume.

“They [Model 3 production] were borrowing people from our line all day to cover their breaks so the line would continue to move.”

Tesla reportedly disputed this claim.

CEO Elon Musk’s supervision of the production line led to tensions rising, as he snapped at engineers if production slowed or a problem was encountered with the machines, according to a factory worker.

Tesla’s production problems with the Model 3 have been well documented, calling into question the company’s capability of producing the number of cars for which it has taken deposits.

Last month, Musk tweeted that the company had set up a temporary production line to help achieve Model 3 production goals. This is reported to account for around one-fifth of Model 3 production.

Despite the negative press around the “production hell” of the Model 3, the 5000-a-week target for the end of the second quarter was met, although critics are questioning whether this is sustainable, given the increasing pressure put on the Fremont factory and its employees.

Read more:

Tesla Model 3 to make European debut at Goodwood

US Tesla Model 3 customers asked for $2500 confirmation deposit

Join the debate

Add your comment

Too little, too late?

Are the employees rushing the assembly process?

Are the cars being fully quality checked before delivery to customers?

Quality usually suffers when things are rushed. Problems can be missed. Mistakes can occur when employees are tired.

Tesla will probably find that some of the staff will find alternative employment elsewhere. Then Tesla will have to reduce working hours - leading to lower rates of production. Mr Musk will have to hire more staff - pushing costs up significantly.

Tesla is in trouble. Will they survive? I have no idea.

Over-worked

No workforce can work like this continuously without making mistakes... Yes the facilities will improve, and that should ease the stress, but when it comes down to it Tesla are still throwing mountains of money at the problem and ruining the thin margins the Model 3 was meant to be working to. Thin margins don't allow for new buildings, or new facilities, or overtime for multiple trim halls, or weekend working, or any of the things needed to magic up additional production capacity. With a company that was already struggling heavily at maintaining quality output, increasing production volumes in this way is really not what they should be doing.

Realistically, Tesla wasn't quite ready for this car. They should probably have gone with the Model Y, and increased production volumes in a less cliff-edge way. Either that, or limited pre-orders on the Model 3 to a volume that they could manage, but I suspect that without the circa $500million interest-free loan from dedicated fans, they probably wouldn't have even made it this far.

Go Tesla!!

Still think Elon Musk is a genius?, wonder if he’s paying overtime?, sounds like the Swan anology doesn’t it?