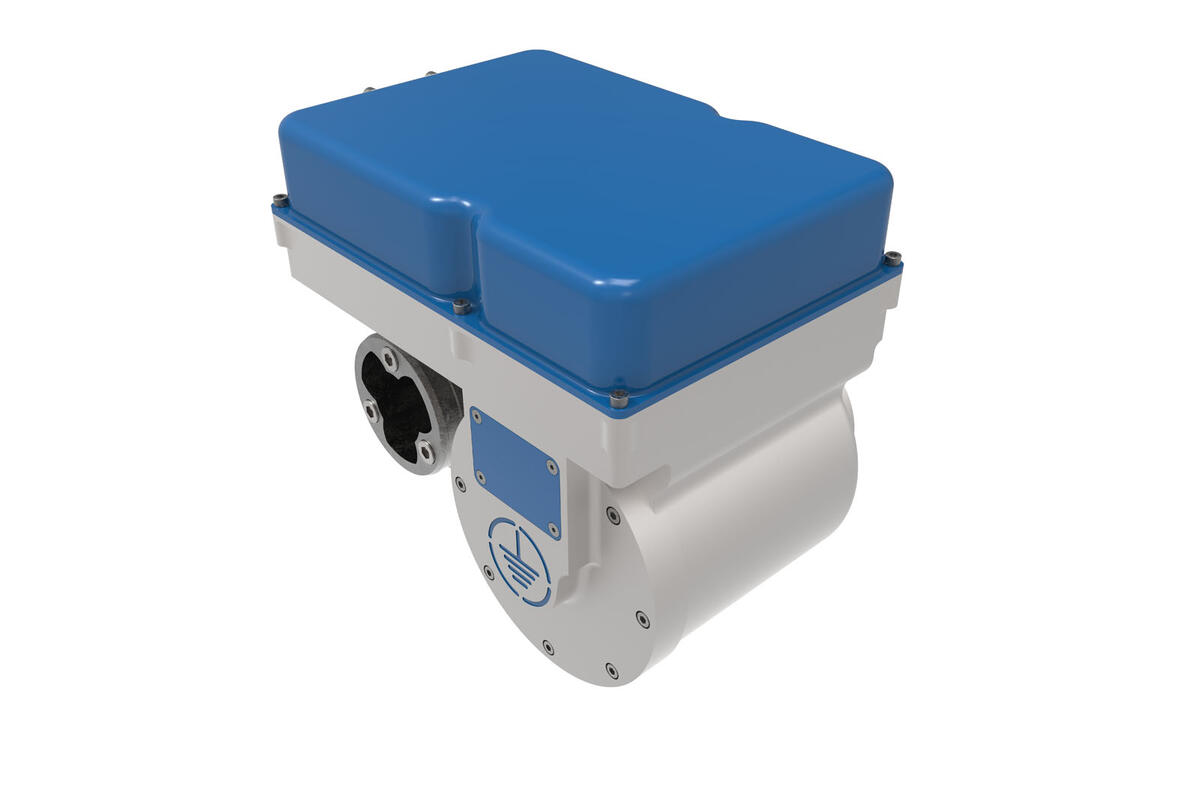

UK-based engineering firm Equipmake is developing what it claims is “the world’s most power-dense permanent magnet electric motor”.

Designed in collaboration with 3D printing specialist Hieta, the so-called Ampere motor will weigh less than 10kg but provide a peak output of 295bhp. For reference, the Jaguar I-Pace’s two electric motors weigh around 40kg each and produce 197bhp.

The Ampere’s 27bhp per kg output gives it a better power density rating than any conventional electric motor on sale.

The unit’s lightness is due mostly to minimal use of metal in its construction, and an innovative 3D-printed casing that is as thin as possible. An added benefit of this construction method is enhanced thermal efficiency, which means the motor can spin faster for longer without overheating.

Despite its impressive performance, the Ampere will command a relatively low list price, given its resource-light construction.

The motor’s development has been funded by the Government’s Innovate UK programme, which gives financial support to UK-based projects.

Working prototypes are expected to be in operation within the next 12 months.

Read more

How Equipmake is revolutionising electric car propulsion

Swindon Powertrain creates compact ‘crate’ electric motor

Under the skin: this new EV motor is small but mighty - like the firm behind it

Join the debate

Add your comment

Isn't 3D printed plastic

Isn't 3D printed plastic relatively low melting temperature? I would be worried about 300bhp coming out a unit with a lightweight casing made of a plastic that gets soft with heat.

Instead of bust pistons you could see magnets flying out from under the bonnet!

The Apprentice wrote:

No these will be metal printed from powder.

10 to 1

10 to 1 hyundai and kia will form a partnership just like theyve done with nearly every EV ide/company/startup

Good news

I am a realist and understand some of the negative points raised about this, but that's all stuff that might go wrong - the story itself is something to be proud of.

Well done to them and hope everything goes well with taking it forward - now all we've got to do is sort out a more practical power source than heavy / environment damaging / expensive / cumbersome batteries :)