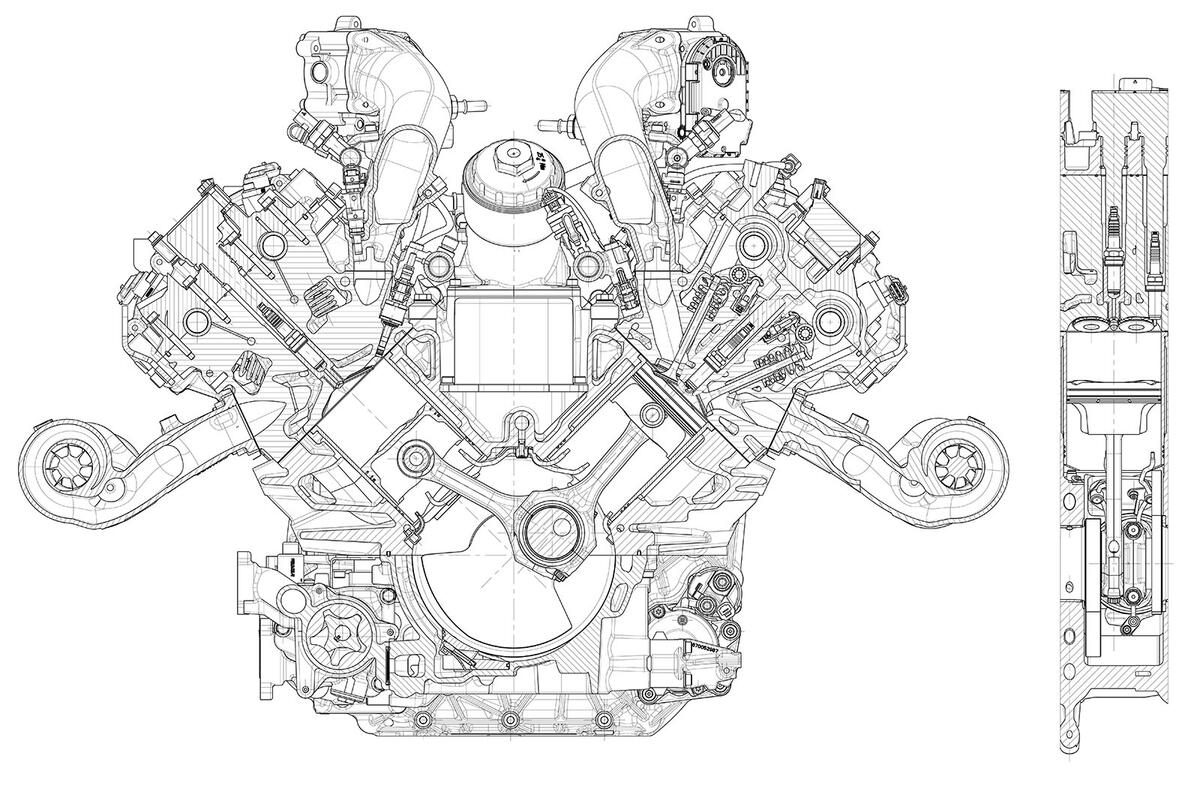

Following two announcements of stonking new supercar engines earlier this year, for the Aston Martin Valkyrie and Gordon Murray Automotive T50, Maserati has made it a hat-trick. Called the Nettuno, its engine is a 621bhp twin-turbocharged 3.0-litre V6 producing 538lb ft torque, and it’s far from conventional, with an all-new pre-chamber combustion system so far used only in Formula 1. The Nettuno will make its debut at the launch of the new Maserati MC20 supercar in September.

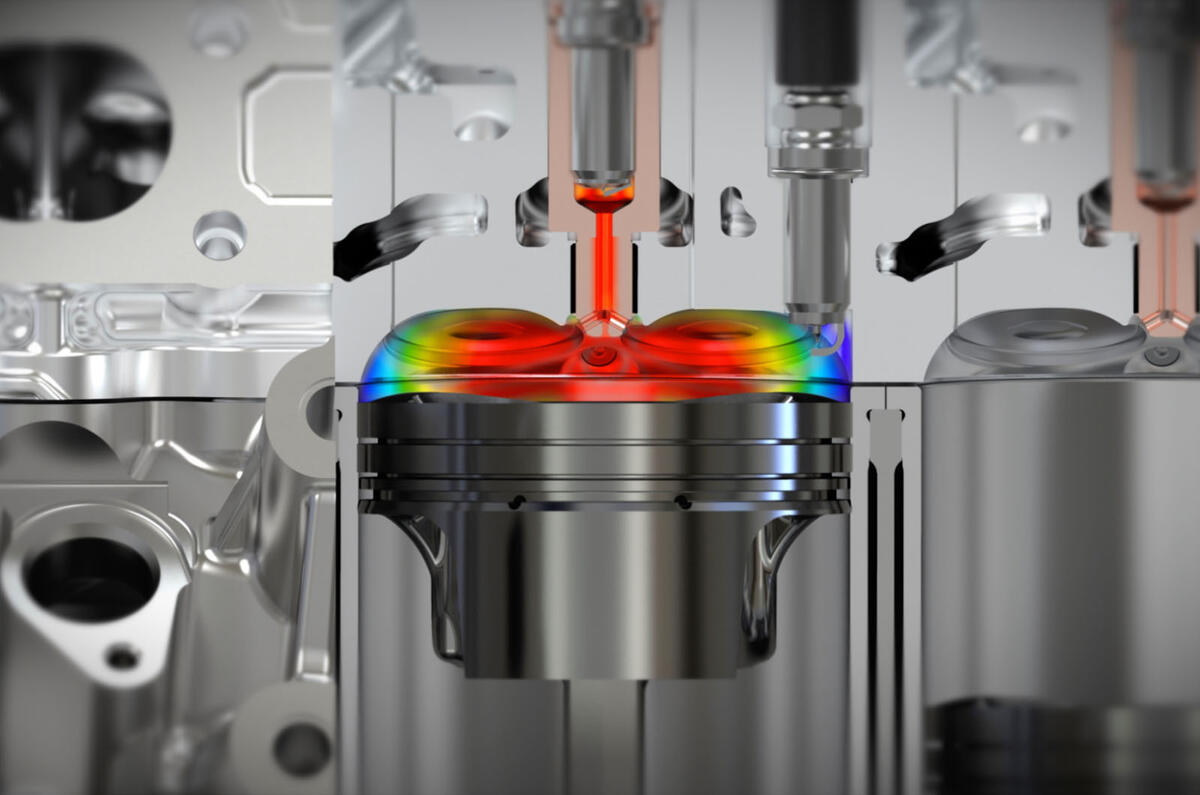

The concept is similar to but mechanically simpler than the Mahle Jet Ignition prechamber concept that we looked at in the 8 January issue. The idea is that rather than compressing and firing a single charge of fuel and air in the combustion chamber as normal, some of the mixture is initially ignited in a small pre-chamber that sits above the combustion chamber and is connected to it by small nozzles.

The mixture in the pre-chamber is ignited by a spark plug mounted inside it, just as the piston is about to fully compress the main charge of fuel. As the charge in the pre-chamber ignites, jets of flame shoot out from the pre-chamber nozzles into the main charge, igniting it. The advantage is that the fuel-air mixture is ignited at multiple points rather than at the single site of a spark plug.

The Mahle system is ‘active’, with two direct injectors: one to fill the pre-chamber and the other to inject the main charge. The Maserati system takes its cue from the Compound Vortex Controlled Combustion system used in the Honda Civic in the 1970s.

Maserati uses one high-pressure (350bar) direct injector per cylinder to deliver the main charge into the main combustion chamber as the piston is on its upward stroke. Some of the charge is forced through the nozzles into the pre-chamber as the piston rises, to be ignited by a spark plug.

When that happens, high-pressure jets of fuel-air mixture are driven through the nozzles back into the main combustion chamber to ignite the main charge in the same way as the active system. Igniting the charge at multiple points raises the knock threshold (the point at which the fuel and air explodes rather than burns), allowing higher boost pressures to generate more power.

When that happens, high-pressure jets of fuel-air mixture are driven through the nozzles back into the main combustion chamber to ignite the main charge in the same way as the active system. Igniting the charge at multiple points raises the knock threshold (the point at which the fuel and air explodes rather than burns), allowing higher boost pressures to generate more power.

Join the debate

Add your comment

It may well be "developed and built in house" but key measurements, engine block, 92mm stroke, ancillary parts, are all in common with the Alfa Romeo 2.9 which in turn is 3/4 of a 388's V8. Bore is increased by 1.5mm, which explains the slightly bigger capacity. The carbonfibre tub is a larger and improved version of the 4c's, with much improved and more sophisticated geometry (instead of the dreadful McPherson of the 4C's rear). What a great car this will be.

Marvellous

No all we have to do is make a 200bhp plus per liter engine work OK when it's sat in traffic and the turbo charger is left to heat soak etc, these types of "power blasted" engines are suited to race cars not daily drivers as several manufacturers have found out. All this business about pre-chambers and nozzle pressures and such like is all well and good however what are the load bearing parts of the engine made from? have they been strengthened to cope with the strain?...likely not, another turbocharged car that'll be good for 3-5 years and then need scrapping but the manufacturers don't care once it's been bought by a leasing company or on finance and is no longer their responsibility..after 3-5 years.

405line wrote:

You sound jaded.

I reckon a brand new highly boosted V6 from one of the grandest marques featuring innovative combusion chamber technology sounds pretty damned exciting, personally!

Poor editing

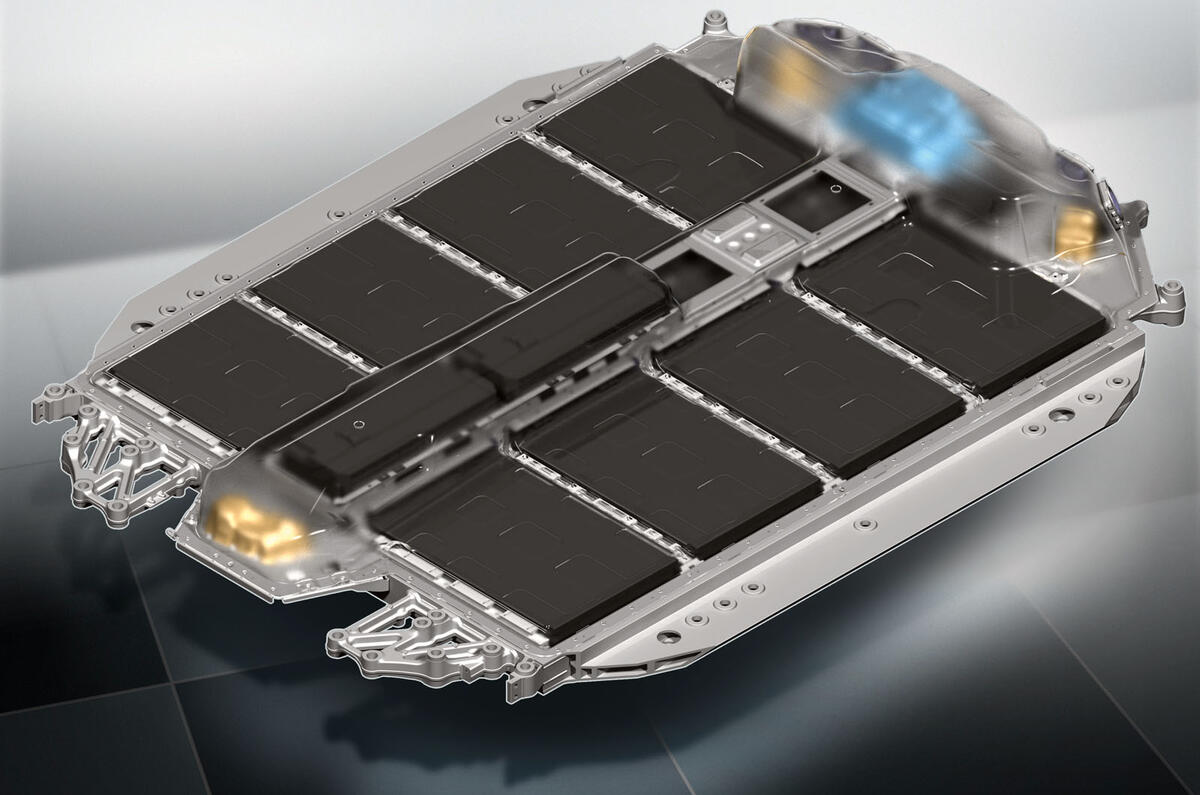

What has the last paragraph and preceding photo got to do with the Maserati engine?